Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CAS No.

- 7631-86-9

- Technologies

- Product Families

Features & Benefits

- Product Overview

Antiblocking agents are essential additives in the production of plastic films. These additives help facilitate film winding operations and improve the handling properties of films during subsequent processing. Under the brand names SPHERILEX® 30 AB and SPHERILEX® 60 AB, Evonik has introduced two grades of precipitated silica to the antiblock market. These products are produced by a new, patented manufacturing process that simultaneously allows spherical particle shape, controlled particle size, and narrow particle size distribution to be achieved. This unique combination of product properties offers significant benefits, especially for application as an antiblocking agent in blown and cast films including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polyamide (PA).

SPHERILEX® 60 AB was developed for standard films based on PE and PP, whereas SPHERILEX® 30 AB is specially designed for very thin films and biaxially oriented film applications.

- Main benefits of SPHERILEX® Antiblocking Agents

- Spherical particle morphology

- Narrow particle size distribution

- Low coefficient of friction (COF) of films

- High film transparency

- Excellent performance in combination with a slip agent (low oil absorption)

- Easy dispersibility and high masterbatch loading

- Low abrasion of processing equipment

- Product Benefits

Low Coefficient of Friction, high transparency, good dispersibility, low absorption of additives.

Properties

- Physico-Chemical Properties

| Value | Units | Test Method / Conditions | |

| Wet Screen Residue (min. 25µm) | max. 0.01 | % | ISO 187-18 |

| Specific Surface Area (N₂) Multipoint | 100 | m²/g | ISO 9277 |

| SiO₂ Content | min. 97 | % | ISO 3262-19 |

| Sieve Residue (min. 25 µm) | max. 100 | ppm | Mocker Apparatus, ISO 787-18 |

| pH Value (in 5% water) | 7.5 | — | ISO 787-9 |

| Particle Size (D50) | 4 | µm | Laser Diffraction, ISO 13320 |

| Loss on Drying (at 105°C, 2 Hours) | max. 2 | % | ISO 787-2 |

| Linseed Oil Absorption (at 105°C, 2 Hours) | 80 | ml/100g | ISO 787-5 |

| ISO Brightness | min. 95 | % | ISO 2470 |

| Dynamic Void Volume (DVV) (at 10 MPa) | 70 | cc/100g | Internal Method |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

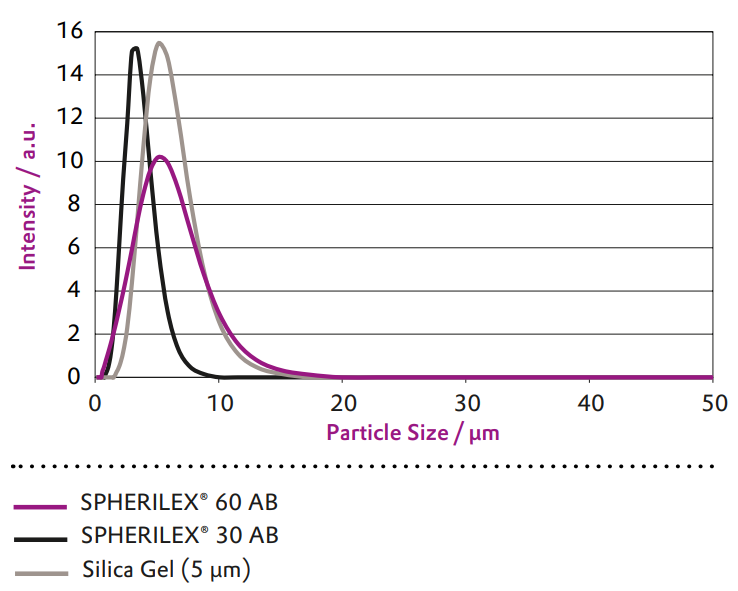

- Particle Size Distribution

Figure 1 : Particle size distribution (HORIBA) of SPHERILEX® 30 AB and SPHERILEX® 60 AB compared with a 5 µm silica gel

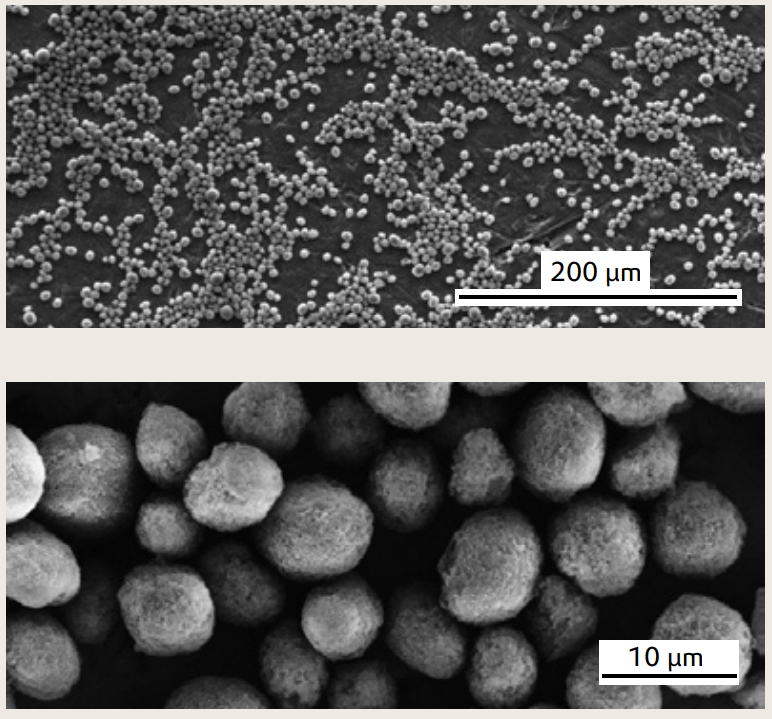

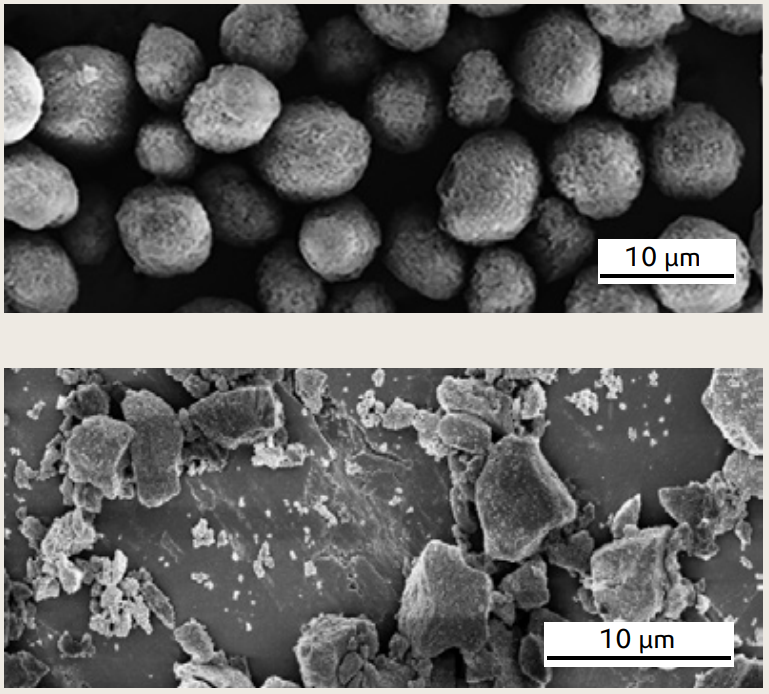

Figure 2: SEM micrographs of SPHERILEX® 60 AB at different magnifications

Figure 3: SEM comparison of SPHERILEX® 60 AB and silica gel

Figure 1 shows the particle size distribution of the new SPHERILEX® grades along with the silica gel reference. The spherical particle morphology can be seen in a SEM micrograph (Figure 2) and in comparison to a silica gel in Figure 3.

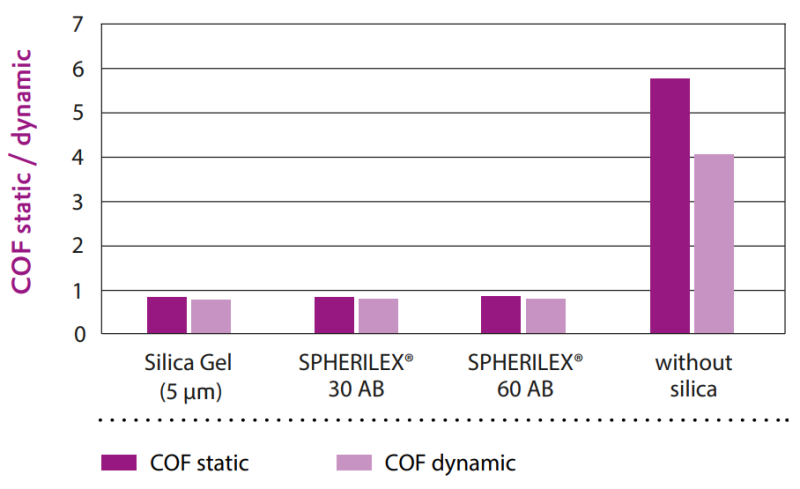

- Application Example in PP Cast Film

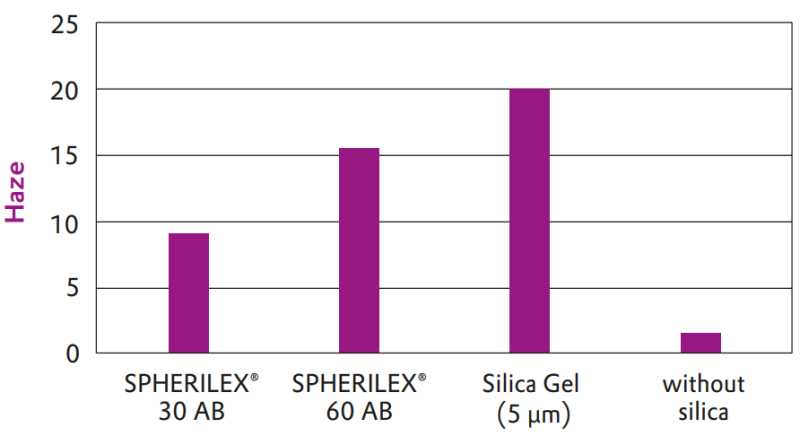

Figure 1: Coefficient of friction in PP cast film, 30 µm / addition of 0.2 % silica + 0.1 % slip agent

Figure 2: Haze in PP cast film, 30 µm / 0.2 % silica + 0.1 % slip agent

Figures 1 and 2 demonstrate the high level of performance of SPHERILEX® 30 AB and SPHERILEX® 60 AB as antiblocking agents. They achieve excellent antiblocking performance (low COF) and high film clarity (low haze). They also have low interaction with other polymer additives and therefore perform very well in combination with a slip agent. They are easy to disperse in thermoplastic compounding processes, which facilitates high masterbatch loadings.

- Application Example in LDPE Blown Film

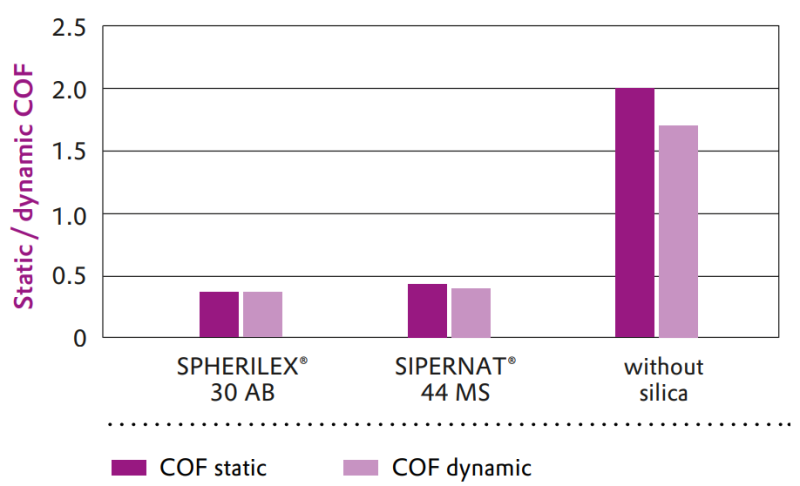

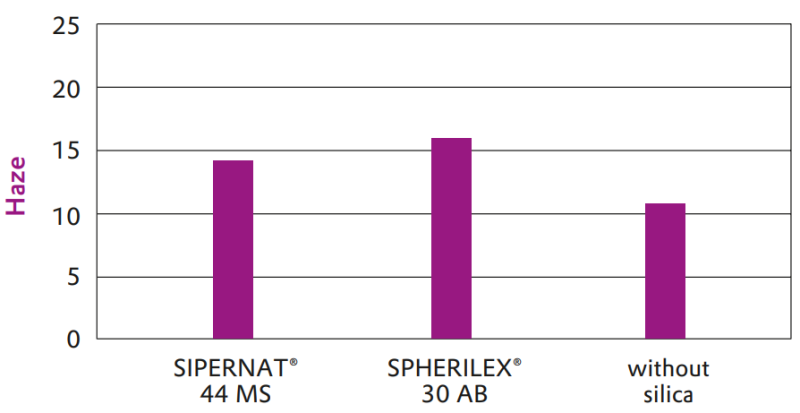

Figure 1: Coefficient of friction in LDPE blown film, 25 µm / addition of 0.15 % silica + 0.05 % slip agent

Figure 2: Haze in LDPE blown film, 25 µm / 0.15 % silica + 0.05 % slip agent

Figure 1 and 2 show that SPHERILEX® 30 AB matches the very favorable performance of zeolite based antiblocking agent SIPERNAT® 44 MS, both for the coefficient of friction as well as clarity of the PE film. The very low moisture content is an additional benefit for SPHERILEX® 30 AB.

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 24 months

- Storage Conditions

Our silica products are inert and extremely stable chemically. However, due to their high specific surface area, they can absorb moisture and volatile organic compounds from the surrounding atmosphere. Therefore, we recommend storing the products in sealed containers in a dry, cool place, and removed from volatile organic substances. Even if a product is stored under these conditions, after a longer period it can still pick up ambient moisture over time, which could lead to its exceeding the specified moisture content. For this reason, our recommended use-by date is 24 months after date of manufacture. Product more than 24 months old should be tested for moisture content before use in order to make certain that it is still suitable for the intended application.