Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Benefits of Plastic Coolant Lines

Coolant line systems made of plastics offer many advantages over conventional metal systems or elastomer hoses. They are lighter, thinner because of their strength, and easier to thermoform. In contrast to metal lines, they are not susceptible to corrosion and resist vibration cracking. They are easily and quickly joined by means of quick connectors, making them more economical than both conventional systems. Compared to elastomer hoses, the outer polyamide layer also provides low tempera-ture impact strength, and stone impact resistance.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Production

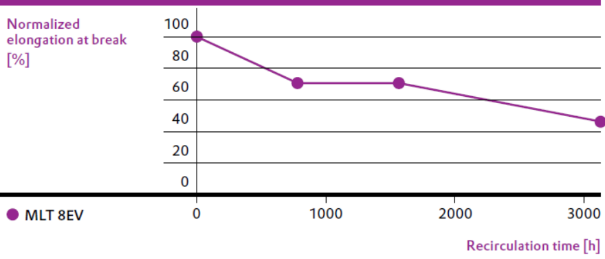

Tubing of the MLT 8EV can be manufactured by conventional coextrusion technology at line speeds normally used for monowall tubing. The assembly of MLT 8EV with the various components is done with the same techniques used for monowall tubing. The mechanical properties are nearly comparable to the long-proven polyamide 12 monowall tubing. With an outer layer of VESTAMID® polyamide 12 and a special polypropylene inner layer the system offers high hydrolysis resistance against coolant liquids and urea solutions, good cold impact performance and significantly weight savings compared to less innovative concepts (metal/ rubber hoses).

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Stress at Yield (virgin) | 22 | MPa | ISO 527 |

| Strain at Break (Virgin) | min. 150 | % | ISO 527 |

| Modulus of Elasticity (Virgin) | 750 | MPa | ISO 527 |

| Cold Impact Resistance (-40°C, Virgin) | 0/10 | failures/specimen | SAE J2260 |

| Burst Pressure (Virgin) | 23 | N/mm² | DIN 53578 |

| Stress at Yield (after Re-circulation) | 29 | MPa | ISO 527 |

| Strain at Break (After Re-circulation) | min. 150 | % | ISO 527 |

| Modulus of Elasticity (After Re-circulation) | 780 | MPa | ISO 527 |

| Cold Impact Resistance (-40°C, after Re-circulation) | 0/10 | failures/specimen | SAE J2260 |

| Burst Pressure (after Re-circulation) | 30 | N/mm² | DIN 53578 |

Technical Details & Test Data

- Test Data