Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Benefits

- Flame retarded (UL94V-0)

- Nucleated to allow high crystallinity and heat deflection temperature

- High Impact Strength

- High renewable content

- Developed for applications requiring fire resistance

- Durability comparable to flame retarded ABS

- Contains elastomeric impact modifier

- Floreon is a HALOGEN FREE alternative to Flame Retarded ABS

- Floreon’s base material (PLA) is ideally suited to chemical recycling.

- In pilot plant /kilo lab trials with the Biorenewables Development Center, Floreon were able to recover 100% of the lactic acid feedstock in a simple and fast reaction, removing ALL flame retardant and fillers by simple filtration.

- This feedstock can then be used to regenerate virgin polymer with no downcycling.

- Is commercially viable.

- Functions the same as traditional plastic.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Injection molding

- Consumer electronics

- Extrusion

- 3D Printing

- Electronics and electricals

- home appliances

- plug casings

Properties

- Flame Rating

- Physical Properties

- Mechanical Properties

- Thermal Properties

- Shrinkage

- Impact Properties

| Value | Units | Test Method / Conditions | |

| Melt Flow Index (at 190°C, 2.16 kg) | 10.0 | g/10 min | Internal method |

| Specific Gravity | 1.26 | g/cm³ | ISO 1133, ASTM D792 |

| Value | Units | Test Method / Conditions | |

| Tensile Strain (at break) | 9.9 | % | — |

| Tensile Strength (at yield) | 36.6 | MPa | — |

| Young’s Modulus (at 23°C) | 2.57 | GPa | ISO 527 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature | 175.0 | °C | DSC |

| Value | Units | Test Method / Conditions | |

| Shrinkage (Amorphous, at mould temperature 26°C) | 0.2 - 0.4 | % | ASTM D638 |

| Shrinkage (Amorphous, at mould temperature 120°C) | 1.7 - 1.8 | % | — |

| Value | Units | Test Method / Conditions | |

| Fire Resistance (0.8mm) | V0 | — | UL94V |

| Fire Resistance (3.2mm) | V0 | — | UL94V |

| HDT (Mould heated to 95°C) | 90.0 | °C | ISO 75-2/B |

| Heat Deflection Temperature | 55.0 | °C | Internal method |

| Notched Izod Impact Strength (at 23°C) | 5.03 | kJ/m² | ISO 180 |

Regulatory & Compliance

- Certifications & Compliance

- REACH Declaration

- Floreon is fully compliant with REACH regulations.

Technical Details & Test Data

- Processing Information

- Floreon Therma Tech compound can be processed on general purpose injection molding equipment and a screw designed to minimize shear and residence time will produce the best results.

- The material is typically injection molded using a melt temperature of 200°C with a mold temperature of 26°C. This grade can be extruded from as low a temperature as 170°C, but processing temperatures must never exceed 240°C.

- Melt temperature has a significant effect on mold flow with this grade and for thinner walled parts a melt temperature of 230°C may be required.

- Recommended Machine Settings Injection

Processing Temperature Profile :

Melt Temperature 200°C Feed Throat 20°C Feed Temperature 60°C Compression Section 165°C Metering Section 190°C Nozzle 190°C Mold 26°C - Drying

- Floreon resins must be dry before use in melt processing; a water content of less than 250 ppm is recommended, otherwise product performance will be significantly degraded.

- The solid resin will not be damaged by absorption of atmospheric moisture providing it is stored in a cool environment at temperatures not exceeding 25°C.

- As with unmodified PLA, Floreon resins should not be left in the barrel at high temperatures for extended periods of time (5 minutes and above) as this will degrade the material resulting in a significant drop in viscosity and resin integrity.

- Drying under vacuum at a maximum temperature of 90°C for 2 hours is recommended to ensure best results. The material can be dried above this temperature but some ‘clumping’ may occur, with pellets sticking together. This is reversible and the pellets can be separated on cooling with mild agitation.

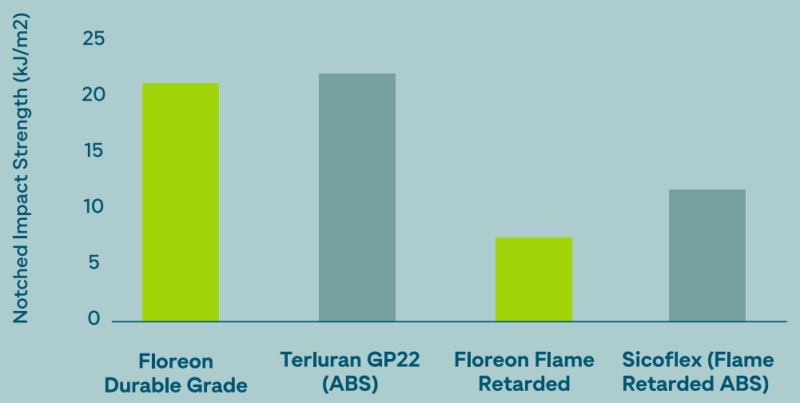

- Benchmarking of Floreon vs ABS

Floreon’s durable and flame retarded grades were tested alongside a high performance ABS and flame retarded ABS grade to provide a benchmark. Floreon is able to match the notched impact strength of ABS. Molded products have also passed all necessary drop testing.

Notched Impact Strength Comparison