Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Characteristics

- One coat finishes.

- Excellent UV resistance.

- Superdurable powder.

- Suitable for most exterior environments.

- 15 years guaranteed performance on correctly pre-treated aluminum.

- Tgic free.

- Good flow out.

Applications & Uses

- Markets

- Applications

- Application Method

- Applications

- Specially developed for use on extruded architectural aluminum, including window and door frames, and extruded panel work on commercial buildings

- Application Data

- Application Corona/Tribo (Can be applied by tribo guns if product code has “T” for the 6th character).

- Curing - 190°C, 10 minutes recommended.

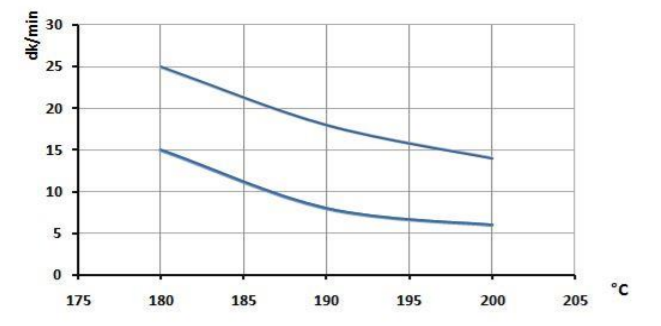

Metal Temperature (°C) Time (minutes) 190 15 - 25 200 8 - 18 210 6 - 14 - Theoretical cons. 9-12 m2/kg. Practical spreading rates will vary due to such factors as method and conditions of application, specific gravity, surface profile and texture.

- Application Guide

Surface Preparation:

All surfaces should be degreased and pretreated for optimal performance.

Suitable pretreatment includes:- Aluminum Yellow chromate or green chromate/phosphate

- Ferrous metals Zinc phosphate or Iron phosphate

- Zinc Coated Metals Zinc phosphate or chromate

Application Procedure and Equipment:

- PS60 series powder coatings charging properties are optimized when powder is free-flowing and moisture-free. Aged or compacted powder may require preconditioning for several minutes to fluidise evenly.

- If storage room temperature is lower than the application area, powder coatings, which are hygroscopic, should be acclimated in unopened containers prior to adding into the spray hopper. For optimum performance, It should be applied and stored at air-conditioning area. Storage temperatures should be kept below 30°C.

- Powder should not be stored in hoppers for long periods of time. If moisture condensation occurs, fluidize powder to dry-out or replace moisture-laden powder with virgin powder.

- Powder coatings are finely ground particulates. Respirators or dust masks should be used by workers exposed to powder in order to avoid dust inhalation.

- Compressed air to the gun must be oil and moisture free.

- Silicone should not be used in application area.

- For box feeders, ensure probe is fully inserted in powder and operated as per manufacturer’s recommendations.

- Contact points should be maintained to ensure metal-to-metal ground.

- Apply by electrostatic spray. Relative humidity should be 50-60% for corona system, lower than 40% for tribo system.

- Cure as per recommendations outlined above.

- Reclaim-to-virgin ratios should be carefully monitored to maintain spray consistency.

- Sieving powder before adding to hopper eliminates potential clumping or foreign matter.

- Test for cure of the coating by impact test.

- Care and Maintenance

- PS60 should be regularly washed with warm water and mild liquid detergent, followed by a fresh water rinse to maintain the attractive appearance of the powder cured film.

- The use of abrasive cleaners is not recommended, nor is the use of active organic solvents.

- Precautions and Limitations

- As a result of possible wide application variations and stoving conditions, PS60 may show variation, between İBA Kimya Powder Coatings prepared samples and production applied material. Therefore, it is the applicator and/or their customer’s responsibility to ensure the product conforms to their requirements.

- For optimum performance ensures recommended dry film thickness is obtained.

- Due to water release during curing process, pin hole problem can be seen above 100 μm.

Properties

- Typical Properties

- Product Properties

- UV Resistance - Very good UV resistance.

- Flow out - Very good

- Surface - Gloss GL

| Value | Units | Test Method / Conditions | |

| Specific Gravity (Low with Dark Colours, High with Light Colours) | 1.2 - 1.7 | gr/cm³ | — |

| Film Thickness (Recommended) | 60 - 80 | μm | — |

Safety & Health

- Health and Safety

- The SDS is an integral part of using this product as it contains information on the potential health effect of exposure, personal protective equipment needed. It is recommended to contact to Sales and Customer Service Offices for further information.

Packaging & Availability

- Packaging Type

Storage & Handling

- Shelf Life

- 24 months (max. 30°C and max. 50% RH)

- Transport and Storage

- Packaging - 15-20-25 kgs. Heavy polyethylene bag in a corrugated carton

- Shipment - Not dangerous goods. No special transport requirements.

- Storage Conditions - Storage temperatures should be kept below 30°C and 50% relative humidity. Powder should be stored in closed containers.