Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

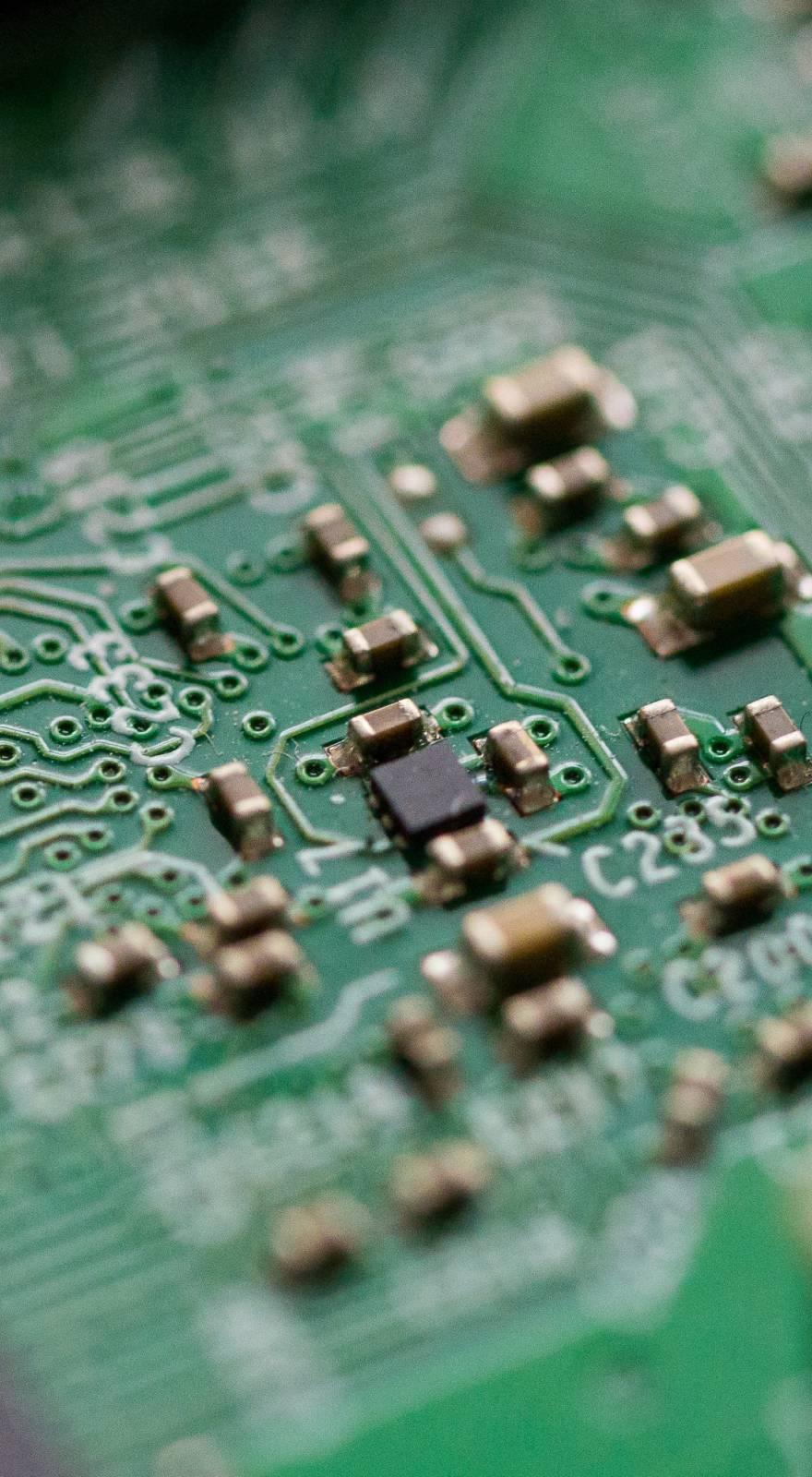

• Designed for moisture and corrosion protection of printed circuit boards and electronic components

• Is UV (ultra violet) light detectable for easy identification of coating and quality control

• Low surface energy allows lubricating oils, silicones, photoresist solutions, etc. to bead and drain freely from coated surfaces

• Helps provide repellency and antiwetting properties against liquids – water, hydrocarbons, silicones and photoresists

• Helps protect against corrosive gasses and vapors in addition to liquids

• The polymer can endure up to 175°C for 24 hours and maintain repellency

• Essentially insoluble in solvents such as heptanes, toluene and water

• Adheres to a variety of materials (metals, glass, ceramics, polymers, composites, laminates)

• Thermally and electrically stable with good dielectric properties

• Easy to apply – dries quickly without the need for post-application curing

• Excellent surface wetting, especially under low standoff SMT components

• Allows solder-through repairability

• Non-flammable, non-ozone-depleting, and low in toxicity

• Low in global warming potential (GWP), RoHS compliant and and contains less than 5% volatile organic components (VOCs)*

Applications & Uses

- Markets

- Application Area

- Application Method

- Applications

Helps provide:

• Moisture, chemical and corrosion protection for printed circuit boards and their components

• An easy and cost-effective alternative to conformal coatings

• Anti-wetting, anti-stiction, anti-migration and anti-corrosion properties in many diverse applications

Can serve as:

• Anti-migration coating for displays, spindle motors or lubricated electronic parts

• Anti-corrosion coating for a variety of materials and components

Application techniques

Coating can be applied by spray, dip, brush or selectively deposited as per the safety and handling requirements. Water should be kept out of coating bath as contact will interfere with coating deposition. Surfaces to be coated should be clean and dry before application. Masking may not be required for larger connector types, but testing is always suggested. The solvent will evaporate quickly, and the fluorinated polymer film will dry in minutes.Application Options Spray, dip, brush and selective dispenseDilution Can be diluted with 3M™ Novec™ 7200 Engineered FluidDrying/Curing Dries at room temperature; can be handled in under two minutesRemovability 3M™ Novec™ 72DA Engineered Fluid (preferred) or removable with Novec 7200 Engineered Fluid

Properties

- Physical Form

- Appearance

- Transparent. Yellow-Orange. Liquid Solution, Transparent. Light Yellow to Orange (Depending on Thickness).

- Typical Physical Properties

- Solder-Through Repairability (Thermal Decomposition Products)

Yes (see SDS for thermal decomposition products)

- Solvent

3M™ Novec™ 7200 Engineered Fluid and <5% of PGMEA

| Value | Units | Test Method / Conditions | |

| Solids (Fluorinated Polymer) | 4.0 | wt% | — |

| Density (23°C) | 1.41 | g/ml | — |

| Viscosity | 1.75 | cP | — |

| Boiling Point | 78.0 | °C | ASTM D1120-94 |

| Flash Point (Per Closed Cup Method) | None | — | — |

| Coating Thickness (Depending on Application Method) | 0.1 - 4.0 | microns | — |

| Solvent and Chemical Resistance | Resists a variety of solvents and chemicals. Dissolves in acetone. | — | — |

| Glass Transition Temperature (Tg) | 53.0 | °C | — |

| Thermal Stability of Dry Film Repellent to Chlorinated Silicone Oil After 24 hours) | 175.0 | °C | MIL-B-81744A |

| Contact Angles (Static, Dip Coated/Dried on Glass Substrate, Water) | 105.0 | ° | — |

| Contact Angles (Static, Dip Coated/Dried on Glass Substrate, Hexadecane) | 65.0 | ° | — |

| Refractive Index | 1.38 | — | — |

| Non-Flammable | Meets UL 94 V-0 | — | — |

| Coefficient of Thermal Expansion - TMA | 88.0 | μm/(m·°C) | — |

| Thermal Conductivity | 0.1 | W/m*K | — |

| Dielectric Constant (30% RH, 1kHz) | 3.2 | — | ASTM D150 |

| Dissipation Factor (30% RH, 1kHz) | 0.001 | — | ASTM D150 |

| Dielectric Breakdown Strength (20°C, 30% RH) | 2500.0 | V/mil | ASTM D149 |

Safety & Health

- Environmental

Low in toxicity, low in GWP, non-ozone depleting, non-flammable, low VOC,* RoHS compliant, contains no chlorine or bromine

Packaging & Availability

- Construction

Solids Solvent Color Container Size 4.0 wt% fluorinated polymer 3M™ Novec™ 7200 Engineered Fluid and <5% of PGMEA Yellow-Orange 1 gal (11 lbs/5kg)

Storage & Handling

- Shelf Life

Two years from date of manufacture in original unopened package

- Storage and Shelf Life

To avoid thermal decomposition, the coating solution should not be heated above 150°C (302°F), and the dried fluorinated polymer should not be heated to temperatures above 225°C (437°F), which, in general, is lower than the onset of thermal degradation under TGA test conditions. When stored under conditions of 16- 27°C (60-80°F) and less than 60% R.H. in the original, unopened container, the shelf life is certified for two years from the date of manufacture. Before using this product, please read the current product Safety Data Sheet (available through your 3M sales or technical service representative or at www.3M.com/Novec) and the precautionary statement on the product package. Follow all applicable precautions and directions. Always practice smart and safe industrial hygiene practices. Do not spray apply without proper ventilation and/or personal protective equipment (PPE).