Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

• Excellent adhesion in harsh weather conditions,

• Fluorescent UV to control of the layer of conformal coating deposit,

• Operating temperature range -55°C to + 150°C,

• Can be soldered through without fear of hightly toxic gasses being produced,

• Resistant to mold growth,

• Excellent dielectric properties,

• Very fast curing under UV exposure,

• Moisture cure for shadowed areas,

• No VOC,

• Space ground reduced compared with solvent bases,

• High speed process, increase of the productivity,

• Low viscosity for select coat machine (used on head SC200, SC280, SC300 and SC400).

• Approved UL94 V0 (QMJU2-E308681),

• Approved UL746E.

Applications & Uses

- Markets

- Application Area

- Cure Method

- Coating Type

- Applications

ABchimie746 E UV can be applied by brush, spray or selective coating machine: Spraying (two crossed layers) 60-80 microns Brushing 40-60 microns Selective coating machine 80-120 microns The relative humidity of at least 50% is recommended for the second polymerization mechanism. Before applying the printed circuit board must be clean, dry and free of moisture. PCBs are humidity sensor, it is important to remove it before coating application. A stage in an oven for 4 hours at 80 ° C is usually sufficient. The varnish ABchimie746E UV contains a fluorescent tracer which permit to check good varnish deposit, inspection of PCBs is facilitated. Fluorescence is more important the thickness applied is high.

Properties

- Physical Form

- Appearance

- Transparent, Transparent Yellow

- Typical Properties

- Cured Properties

- Varnish Removal Method

- Mechanical (micro-abrasion) Locally with stripper DVP

| Value | Units | Test Method / Conditions | |

| Base (Liquid) | Urethane Acrylate | — | — |

| Non-Volatile Residue (Liquid) | min. 97 | % | — |

| Viscosity (25°C, Liquid) | 50 - 100 | cSt | ASTM D4212 |

| Flash Point (Liquid) | min. 100 | °C | — |

| Film Thickness (Liquid) | 30 to 150 | microns | — |

| Value | Units | Test Method / Conditions | |

| Adhesion (Excellent) | Class 0 | ISO 2409 | — |

| Volume Resistivity | 1 x 10¹⁴ | Ohm / cm | — |

| Insulation Resistance (Ω) | 10¹² | Ω | EN 61086 |

| Dieletric Strength | 60.0 | kV/mm | — |

| CTI (DIN EN 60112) | min. 600 | — | — |

| Glass Transition Temperature (Tg) | 16.0 | °C | — |

| CTE (T < Tg) | 200.0 | ppm/°C | — |

| CTE (T > Tg) | 250.0 | ppm/°C | — |

| VRT + Humidity (93%HR / -10°C, 5°C/mn) | 65.0 | °C | IEC 60068-2-38 |

| Thermal Shock (30mn/30mn, 50 Cycles) | - 65 to +125 | °C | — |

| Voltage | min. 1750 | V DC | NF EN 61086 |

| Temperature Range | - 55 to + 150 | °C | — |

| Auto-Extinguishing | UL94 V0 | — | — |

Regulatory & Compliance

- Certifications & Compliance

- Regulations

ABchimie746E UV is compliance with REACH and RoHS regulations.

Technical Details & Test Data

- Preparation of The PCB

PCBs must be free of moisture and perfectly clean (no dust, grease, wax…). Adhesion of the coatings is depending. All traces of flux are eliminated because they can become corrosive and create malfunction of the circuit.

Cleaning

To clean equipment or clean uncured varnish ABchimie746E UV, we recommend using SND or DNS solvent.- Curing Conditions

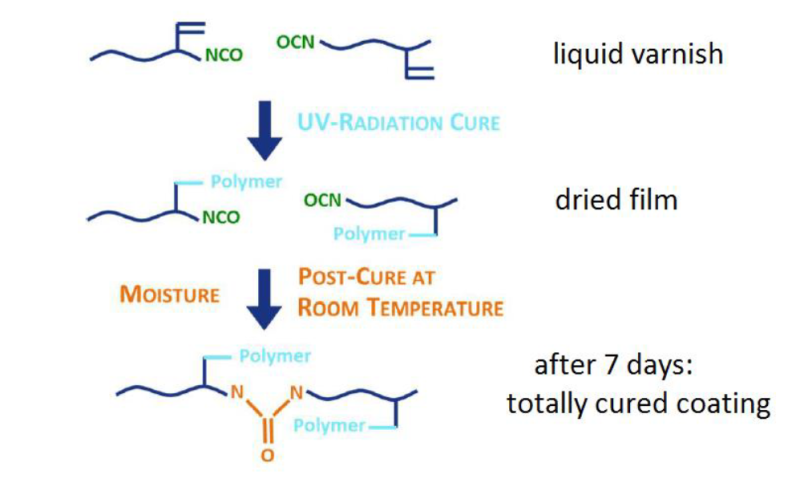

ABchimie746E UV cures with UV rays and moisture for the second cure mechanism.

UV Curing :

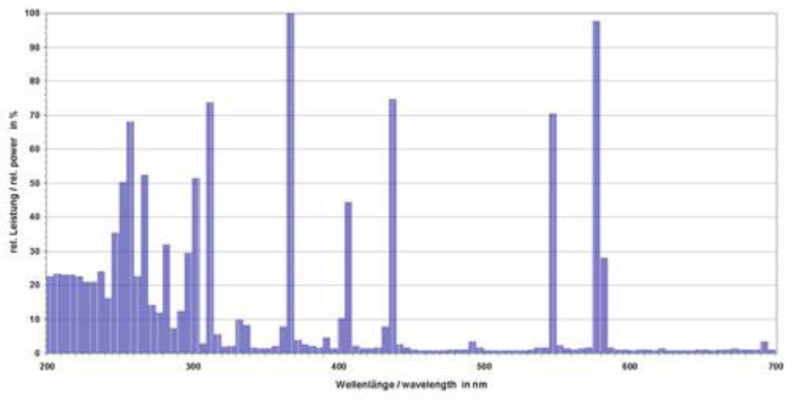

It is important to use the appropriate UV equipment, as well as the parameters recommended to obtain the optimal properties of the ABchimie 746E UV conformal coating. The advised equipment is a mercury lamp.

Emission spectrum of mercury lamp (UV between 200 and 400nm)

Minimum UVA dose : 700mJ/cm² (100μm)

A slight residual tack du to the oxygen in the air can appear. It disappears a few minutes after passing under the lamp.

The UV dose given is a minimum to guarantee a good curing of varnish. A higher dose of UV or a overexposure will not damaged the product.

Moisture cure:

Ambient temperature, 50% minimum relative moisture

Curing mechanism :

Packaging & Availability

- Packaging

Packaging References ABchimie746E UV 1 liter ABchimie746E UV 01L5 liters ABchimie746E UV 05LABchimie746E UV LED (curing with LED radiations) 1 liter ABchimie746E UV LED 01L5 liters ABchimie746E UV LED 05LCleaner Bulk 5 liters SND 05 L Bulk 5 liters DNS 05 L

Storage & Handling

- Storage and Shelf Life

Storage temperature: 5 to 30°C

A temporary lower or higher temperature (maximum 40°C) during few days (transport) doesn’t distort varnish properties.

ABchimie746E UV must be stored in an opaque container, sealed away from excessive heat. The varnish ABchimie746E UV cures under UV action, it musn’t be exposed to any light source.

This varnish also crosslinking with moisture, make sure there is no moisture in the deposition process and in cans open. After opening a bottle, it is recommended to purge these cans started with a dry inert gas (nitrogen) to prevent polymerization of the coating during storage.

Date by use: 12 months after the date of manufacturing