Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Plastics & Elastomers Functions

- CAS No.

- 15520-10-2

- EC No.

- 239-556-6

- Product Families

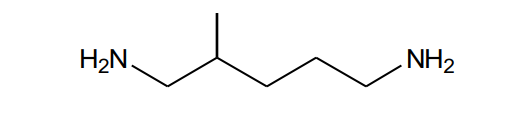

- Molecular Structure

Features & Benefits

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Adhesive & Sealant Type

- Coating Type

- Fluids & Lubricants End Use

- Plastics & Elastomers Processing Methods

- Epoxy Curatives

Epoxy resins cured with Dytek® amines have excellent properties for use in coatings, civil engineering, adhesives, marine, and composite applications.

Features Typical Applications - Low viscosity vs. IPDA

- Chemical resistance

- Highest Tg of all Dytek® Amines

- Tank linings with chemical exposure

- High temperature applications

- Wind turbine blades

- High-performance composite parts

- Applications & Uses

- Polyamide plastics, films, and fibers

- Polyamide adhesive and ink resins

- Corrosion inhibitor

- Epoxy curing agents

- Water treatment chemicals

- Metalworking Fluids

- Isocyanates

- Chain extenders (Polyurethanes)

- Epoxy Applications

Industrial and Marine Coatings:

DYTEK® A amine provides good metal adhesion, chemical & corrosion resistance, and toughness for demanding industrial and marine applications.

Decorative Coatings:

DYTEK® A amine imparts a high gloss, low blush, uniform finish and improves UV stability compared to alternative amines.

Low Temperature Curative:

DYTEK® A amine’s low viscosity and fast cure rate make it an excellent choice for low temperature application and curing.

Accelerator:

When used with slower curatives like polyether- or cyclo-aliphatic amines, small amounts of DYTEK® A amine can reduce gel time while maintaining key mechanical properties of final product.

- Polyurethane and Polyurea

DYTEK® A amine is used as a chain extender in polyurethane applications. Differential reactivity due to the methyl substituent influences cross-linking and crystallinity.

DYTEK® A amine derivatives such as secondary amines, aspartic esters, ketoimines and aldimines can be used as curatives in polyurea systems.

The diisocyanate from DYTEK® A amine can impart unique properties to elastomer and sealant formulations.

- Hot Melt Adhesives

DYTEK® A amine can be used as an alternative to hexamethylene diamine to lower melting point, improve thermal stability and flexibility, and allow for more open time. Aldimine derivatives can be used in moisture-cured polyurethane reactive hot melts.

- Other Applications

Neutralizing or Buffering Agent:

Typically does not produce insoluble salts.

Metalworking Fluids:

Suppresses iron and amine discoloration, improves corrosion resistance and provides effective pH control, extends life by reducing formation of dark color and sediment.

- High Performance Polyamides

DYTEK® A amine acts as a crystallinity disruptor, making polymers more amorphous and slower to crystallize. Potential benefits include lower melting point, improved surface appearance, reduced gelling, reduced melt and quench temperatures, reduced water absorption, improved dye uptake, and increased abrasion resistance.

In addition, DYTEK® A amine may allow for more versatility in polymer composition such as reducing the amount of isophthalic acid needed to maintain transparency or reducing total cost by allowing use of lower cost acids, such as terephthalic acid.

Properties

- Physical Form

- Appearance

- Clear and free of suspended materials

- Miscible In

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| 2-Ethyltetramethylenediamine Content | 0.3 | wt% | — |

| Refractive Index (25°C, nD) | 1.4588 | — | — |

| 2-Methylpentamethylenediamine Content | 99 | wt% | — |

| Amine Equivalent Weight | 58 | — | — |

| Amine Value | 967 | mgKOH/g | — |

| Boiling Point | 192 (378) | °C (°F) | — |

| Color | 2 | APHA | — |

| Critical Pressure (Pc) | 35.3 | atm | — |

| Critical Temperature (Tc) | 383 | °C | — |

| Critical Vapourization (Vc) | 424 | mL/g·mol | — |

| Flash Point | 83 (181) | °C (°F) | Closed Cup |

| Freezing Range | -56 to -60 (-68 to -76) | °C (°F) | — |

| H-Equivalent Weight | 29 | — | — |

| Hansen Solubility Parameters (H-Bonding) | 5.5 | — | — |

| Hansen Solubility Parameters (Nonpolar) | 8.2 | — | — |

| Hansen Solubility Parameters (Overall) | 10.4 | — | — |

| Hansen Solubility Parameters (Polar) | 3.1 | — | — |

| Heat of Combustion (∆Hc) | 9100 | cal/g | — |

| Heat of Vaporization (∆Hv at 193°C) | 92.8 | cal/g | — |

| Methylcyclopentanediamine Content | 0.6 | wt% | — |

| Molecular Weight | 116.2 | — | — |

| Partition Coefficient (Kow) | 0.8 | — | — |

| pH (5% Aqueous Solution at 25°C) | 12.1 | — | — |

| pKa1 (at 25°C (77°F)) | 11.2 | — | — |

| pKa2 (25°C (77°F)) | 10 | — | — |

| Specific Gravity (at 25°C (77°F)) | 0.86 | — | — |

| Surface Tension (at 24°C (77°F)) | 34.9 | dyn/cm | — |

| Viscosity (at 22.6°C (73°F)) | 2.63 | cP | — |

Technical Details & Test Data

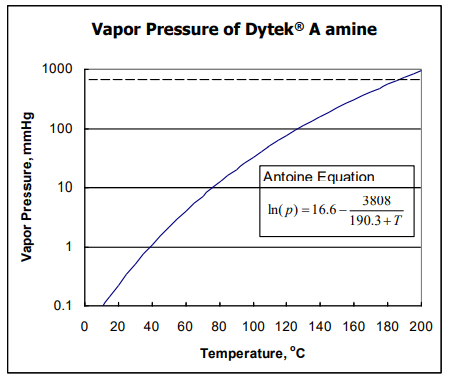

- Vapor Pressure of Dytek® A amine

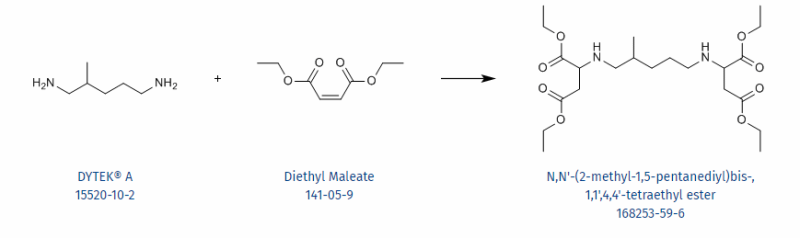

- Aspartic Esters

Packaging & Availability

- Packaging Information

Railcar Net Weight : 140,000/63,500 (lbs/kg) Tank truck Net Weight : 42,000/19,000 (lbs/kg) ISO containers Net Weight : 40,000/18,100 (lbs/kg) Steel Drums Net Weight : 375/170 (lbs/kg) Store DYTEK® A amine under nitrogen padding. Extended storage of DYTEK® A amine in unlined carbon steel vessels may cause color formation. Teflon® fluoropolymer or graphite is preferred for gaskets and packings.