Knowde Enhanced TDS

Identification & Functionality

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Highlights

- Broad compatibility with various surfactant systems

- Easy-to-use liquid form for lower processing costs

- Effective over a wide pH range - 3.5 to 8.5 - and provides increased suspending, stabilizing and thickening benefits through "back-acid" formulating

- Enhances pearlization appearance to improve the visual appeal of pearlizing additives in surfactant-based systems

- Imparts effective thickening, desirable flow characteristics, and permits the formulation of high clarity systems of shampoos, body washes, and other cleansing products

- Provides exceptional suspending and stabilizing properties in surfactant-based systems, even low viscosity formulations

- Similar performance to Carbopol® Aqua SF polymers

- Smooth honey-like flow

- Provides a light, soft sensory on skin

- Silicone and ZPT suspension at low use level

- Good foam volume and creamy foam texture

Applications & Uses

- Markets

- Applications

- Application Format

- Bath & Shower Applications

- Hair Care Applications

- Personal Hygiene Applications

- Use Level

- 9 - 16% (supplied as primary rheology modifier), min. 5 % (supplied as secondary rheology modifier), 1 - 3.5% (Active)

Properties

- Physical Form

- Appearance

- White Liquid

- Odor

- Acrid

- Typical Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Natural Origin Content | 85 | % | ISO 16128 |

| Renewable Carbon Index | max. 0.5 | — | — |

| Value | Units | Test Method / Conditions | |

| Solids Content | 19 - 23 | % | TP-BRK-068 |

| Viscosity (at 25°C) | max. 500 | cP | TP-00042 |

| Ethyl Acrylate | max. 1 | ppm | STP-827 |

| pH (at 25°C) | 2.2 - 4.5 | — | TP-92-B |

Technical Details & Test Data

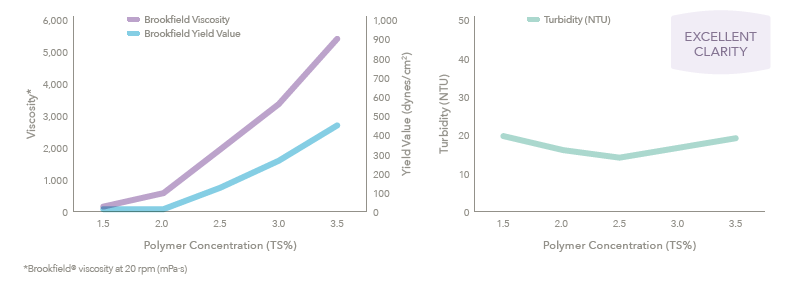

- Performance in Sulfated System

Traditional Sulfated Chasis:

11.2% active Sodium Laureth Sulfate, 2.3% TS Cocamidopropyl Betaine at pH 6.5

Result : Increasing concentration has a positive response for viscosity and yield while maintaining excellent clarity

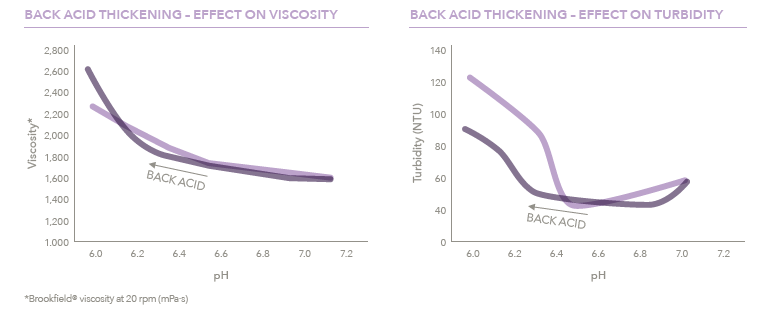

Back-Acid Thickening Technique:

11.2% active Sodium Laureth Sulfate, 2.3% TS Cocamidopropyl Betaine, 2.5% TS Carbopol® Fusion S-20 polymer at pH 6.5

Result : Slightly higher viscosity, and increased clarity with back acid pH adjustment

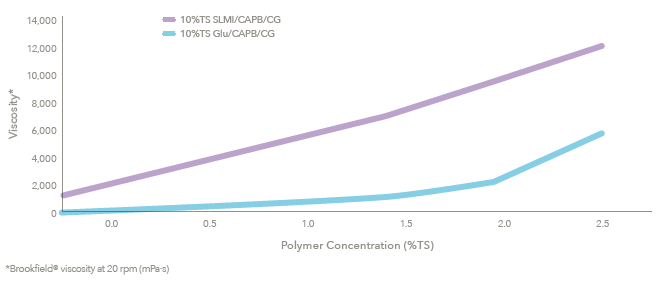

- Performance in Sulfate-Free System

Sulfate - Free Chasis Isoethionate and Glutamate:

5.0% active Sodium Lauroyl Methyl Isethionate, 3.0% active Cocamidopropyl Betaine, 2.0% active Coco-glucoside at pH 5.5-6.0

2.0% active Glutamate, 5.0% active Cocamidopropyl Betaine, 3.0% active Coco-glucoside at pH 5.5-6.0Carbopol® fusion s-20 polymer concentration curve in sulfate-free systems

Result : Excellent viscosity response with Isethionate surfactants and good performance in difficult to thicken Glutamate chassis Increasing polymer level improves viscosity

- Skin Cleansing

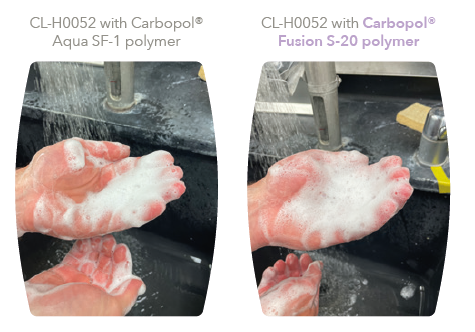

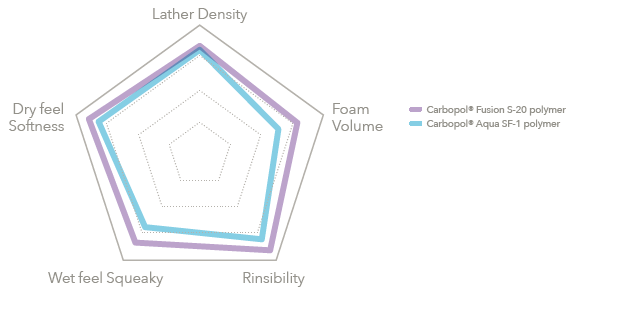

Foam Performance and Sensory:

Foam volume is visually better with Carbopol® Fusion S-20 polymer

Panelist Perceived Sensory:

Sensory is parity with Carbopol® Aqua SF-1 polymer

Clarity:

Sulfate-free Lavender Liquid Hand Soap CL-H0052

Improved visual clarity compared to Carbopol® Aqua SF-1 polymer in this chassis

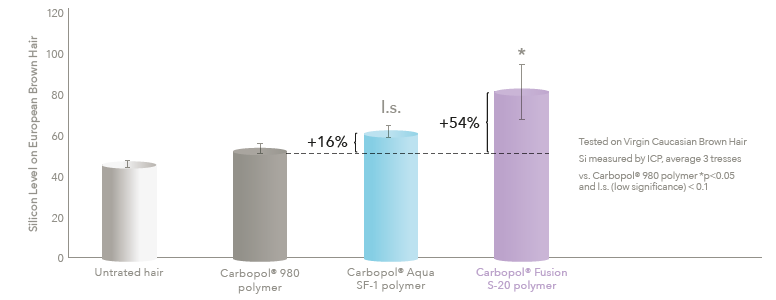

- Hair Care

LPS Silicone Deposition:

2-in-1 Conditioning Shampoo SH-0207B with LPS silicone

SH-0207B silicone on virgin caucasian brown hair - LPS silicone

Result : Formulations containing combination of cationic polymer and Carbopol® Fusion S-20 polymer can show some level of LPS silicone deposition

ZPT Stabilization:

Flake-free Anti-dandruff Conditioning Shampoo with ZPT SH-0204

Appropriate viscosity range, shampoo texture and ZPT suspension capabilities

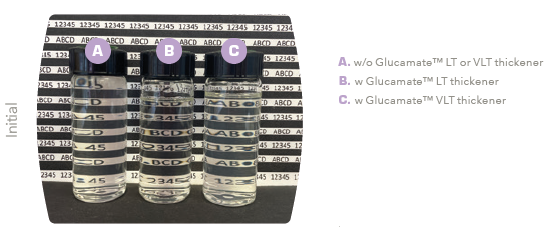

Synergistic Benefit with Glucamate™ Thickener:

Clear Antipollution Sulfate-free Shampoo with Charcoal Beads SH-0202

The addition of co-thickeners leads to increasing viscosity and good clarity, especially with Glucamate™ LT thickener in this chassis for better clarity

Packaging & Availability

- Packaging Information

Note that slight difference in volume and weight may occur between geographic regions based on packaging availability.

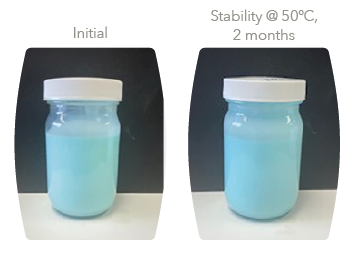

Storage & Handling

- Recommended Retest Period

Recommended retest period is 365 days from the date of manufacture.

- Storage Information

Store in a dry location. Do not store in open, unlabeled or mislabeled containers. Keep containers closed when not in use. Do not freeze. Mild, thorough mixing before use will help to ensure that the polymer is in its original homogenous state.