Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Guar Gum

- Food Additive Number

- E 412, INS 412

- Technologies

Features & Benefits

- Food Ingredients Features

- Product Highlights

- Edicol® brings about stabilization, often in combination with other hydrocolloids, by modifying and controlling the behavior of water in a food or feed. Edicol® may act as the primary or supporting stabilizer ingredient. In various frozen dairy and non-dairy products like ice-creams, ice-milk, ice candies, sherbets, milk shakes etc., Edicol®, either alone or in combination with other hydrocolloids like Carrageenan and Locust bean gum is used to prevent the formation of ice crystals during freeze-thaw cycles, to impart a smooth and creamier texture to the product, to increase overrun and improve chewiness. Edicol® prevents quick meltdown and increases shelf life.

- In cottage cheese dressings, Edicol® promotes curd integrity by lubricity and binds the free water to yield a homogeneous stable product. In soft cheese products, processed cheese spreads and dips, the use of Edicol® helps eliminate syneresis and improve texture and flavor due to better control of moisture and fat/oil migration. Edicol® also increases yield, aids drainage and imparts a soft, compact and tender texture to recovered curd.

- In various baked goods, the use of Edicol® promotes a dough having excellent film properties, particularly in low gluten flours. Baked goods like rolls and breads with Edicol® have an improved shelf life due to better moisture retention, softer textures and higher, loaf volume on baking. Cake and biscuit dough's benefit by incorporating Edicol® leading to better softness, better mold release and less crumbling during slicing. In dry cake mixes, Edicol® offers several advantages it aids one step mixing, gives shorter batter mix time, yields improved internal structure, prolongs shelf life, improves application of icings and frostings and permits freezing of the cake.

- The use of Edicol® in juices, nectars and syrups helps in the homogenous dispersion of pulp during filling and storage. Edicol® also leads to improved mouthfeel in these products. In fruit based beverages, Edicol® helps in solids suspension and can be effectively combined with emulsifiers to prevent separation of flavor oils in the container.

- Features

- Edicol® is one of the most cost effective and efficient water soluble polymers known. It forms highly viscous solutions at low concentrations. It exhibits Non-Newtonian rheological properties and yields acid reversible gels with Borax. Due to the unique properties of this gum, it finds wide application in foods, pet-foods and feeds.

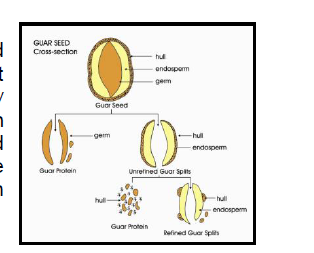

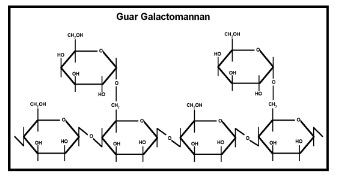

- Edicol® is a plant seed hydrocolloid - a cold and hot water soluble galactomannan polysaccharide derived from the seeds of the Guar plant 'Cyamopsis Tetragonalobus". Chemically, it is composed of a beta 1-4 linked linear mannose backbone chain with single galactose side unit on approximately every other mannose unit, in a 1-6 alpha linkage. The molecular structure reveals that it is a rigid rod-like polymer due to the beta linkage between the monomer units. The mannose to galactose ratio has been estimated at 1.8:1 to 2:1. Recent studies indicate that the galactose side units may not follow a regular spacing pattern, but in fact, may appear in "clusters" and on either side of the mannose backbone and the molecular weight of Guar Gum has been estimated as high as 1.8 - 2.5 million. Depolymerised Edicol® products have significantly lower molecular weights. Usually, viscosities can be directly related to the molecular weight.

- In general, it is the high galactose (to mannose) molar ratio that accounts for the excellent cold water solubility of Edicol®. An important feature of Edicol® structure to be noted is the cis-position of the adjacent hydroxyl groups on the C2 and C3 in the mannose and C3 and C4 in the case of galactose. This is an important factor since these adjacent hydroxyl groups reinforce each other in hydrogen bonding reactions.

- Edicol® is a non-ionic, white to cream white powder, soluble in hot and cold water, but insoluble in most organic solvents. It is commercially used in foods, pet-foods and feeds for its excellent ability to control rheology by economic water phase management. It is neutral in taste, but may have a

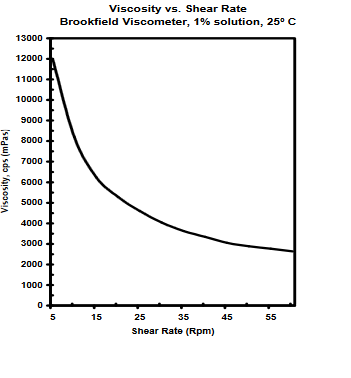

slight characteristic “grassy or beany” odor. - Edicol® forms highly viscous colloidal dispersions when hydrated in cold water. These solutions exhibit non- Newtonian, pseudo-plastic rheological properties. Aqueous solution viscosities decrease with increasing rates of shear.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Applications

- Edicol® brings about stabilization, often in combination with other hydrocolloids, by modifying and controlling the behavior of water in a food or feed. Edicol® may act as the primary or supporting stabilizer ingredient. In various frozen dairy and non-dairy products like ice-creams, ice-milk, ice candies, sherbets, milk shakes etc., Edicol®, either alone or in combination with other hydrocolloids like Carrageenan and Locust bean gum is used to prevent the formation of ice crystals during freeze-thaw cycles, to impart a smooth and creamier texture to the product, to increase overrun and improve chewiness. Edicol® prevents quick meltdown and increases shelf life.

- In cottage cheese dressings, Edicol® promotes curd integrity by lubricity and binds the free water to yield a homogeneous stable product. In soft cheese products, processed cheese spreads and dips, the use of Edicol® helps eliminate syneresis and improve texture and flavor due to better control of moisture and fat/oil migration. Edicol® also increases yield, aids drainage and imparts a soft, compact and tender texture to recovered curd.

- In various baked goods, the use of Edicol® promotes a dough having excellent film properties, particularly in low gluten flours. Baked goods like rolls and breads with Edicol® have an improved shelf life due to better moisture retention, softer textures and higher, loaf volume on baking. Cake and biscuit dough's benefit by incorporating Edicol® leading to better softness, better mold release and less crumbling during slicing. In dry cake mixes, Edicol® offers several advantages it aids one step mixing, gives shorter batter mix time, yields improved internal structure, prolongs shelf life, improves application of icings and frostings and permits freezing of the cake.

- The use of Edicol® in juices, nectars and syrups helps in the homogenous dispersion of pulp during filling and storage. Edicol® also leads to improved mouthfeel in these products. In fruit based beverages, Edicol® helps in solids suspension and can be effectively combined with emulsifiers to prevent separation of flavor oils in the container.

- In canned foods and canned pet-foods, Edicol® is widely used as a viscosifier, processing aid and protective colloids. Edicol® offers the advantages of less wastage due to splattering during the working process, easier pumping of finished product to filling equipment, less splashing and therefore more accurate control during can filling and a homogeneous dispersion of solids in the liquid phase throughout the filling process. The finished goods augmented with Edicol® exhibit good storage stability as there is no migration of fat, and the water and solids are maintained in a good emulsion state. In canned pet-foods, removal of the product from the can is also easier due to the friction reducing properties that Edicol® imparts. A partial replacement of starch and flour with Edicol® in canned foods helps to reduce sterilization and cooling time since it acts as a protective colloid to reduce starch retrogradation.

- Edicol® is used as an effective viscosifier in soups, sauces and gravies, either alone or in comb nation with Xanthan gum and is complimentary to the use of starches. Edicol® helps provide a uniform viscosity to the product over a wide temperature range and imports good cling to sauces and gravies.

- In pourable salad dressings, Edicol® is often used with Xanthan gum and Propylene Glycol Alginate. Edicol® helps to enhance the mouthfeel, gives controlled pourability, suspension of solids and improved cling. Due to Edicol® excellent cold and hot water solubility, it can be very effectively used in instant products like soup and sauce mixes, instant drinks and desserts.

- Edicol® is also used in various restructured or fabricated foods for better water retention and paste workability and integrity before the final structuring of the fabricated food. Edicol® is also used as an additive in food extrusion applications due to its excellent water holding and friction reducing capabilities.

- Edicol® is also used in the preparation of noodles and pasta products; in pickles and relishes and in canned seafood. Fish feed formulations incorporate Edicol® in the dry-mix which aids in the making of an excellent homogeneous fish feed paste when reconstituted with water and fresh minced fish. Edicol® is also used as a binder in feed pellets.

- Edicol®, besides its major function of water retention, viscosifying and thickening is also finding increased use in foods as a source of natural water-soluble fiber; to improve mouthfeel and texture in low fat/no fat foods (specially in combination with certain starches and other hydrocolloids like microcrystalline cellulose); in slimming aids and dietetic foods; in products requiring “all natural” labeling; as a binder, film former and protective colloids; as a stabilizer in sour dairy products.

Properties

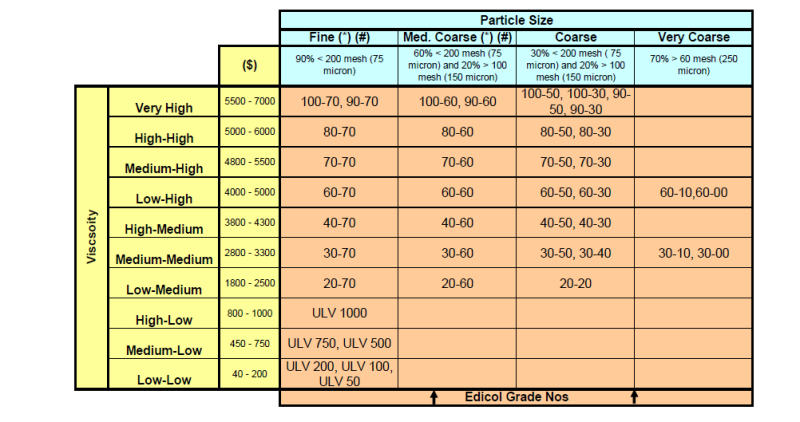

- Particle Size

- ($) = Typical 1% Brookfield Viscosity, cps (mPas), 24 hrs, 25° C.

- (*) Product available with good dry flow properties under nomeclature 'F' added to grade name

- (#) Product available with anti-dust properties under nomeclature 'A' added to grade name

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Product Information

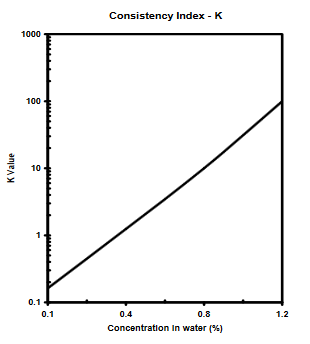

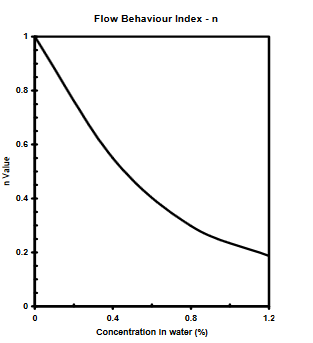

Edicol® aqueous dispersions, like most hydrocolloids, obey the power law: ĸ n

Where stress, = y,shear rate, ĸ = consistency modulus, n = flow behavior index.

- The lower the value of n, the greater the shear thinning effect (loss of viscosity on increasing shear). For an ideal Newtonian fluid, the viscosity is independent of shear and therefore n = 1. Numerous studies have shown that solutions with a high "n" value tend to feel slimy in the mouth. Therefore, when high viscosities and a good, clean mouth-feel are desirable, hydrocolloids like Edicol® with low “n” values are the gums of choice.

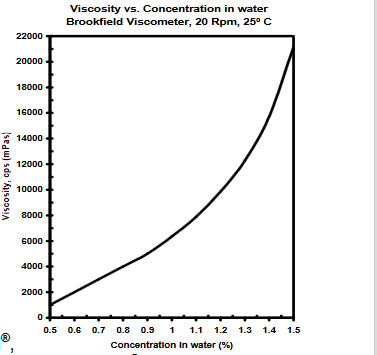

- Edicol® solution viscosities increase exponentially with increasing concentration of Edicol® in water In addition to shear rates and polymer concentration, Edicol® solution viscosities are also influenced by previous shear history, temperature, pH and the presence of salts and other solids. The time required for Edicol® to completely hydrate in water, and reach peak viscosities depends upon the grade of Edicol®, the dispersion and stirring equipment used, the pH and temperature. Edicol® viscosities will tend to irreversibly reduce if the dispersion is sheared at very high speeds for extended periods. Such a reduction is more pronounced at a elevated temperatures and extremes of pH

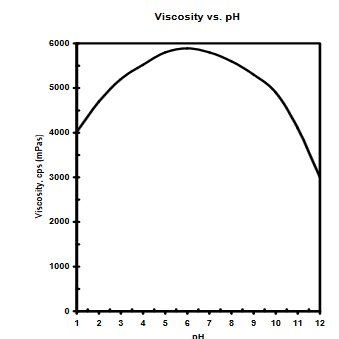

- Edicol® is stable over a wide pH range. Due to the non- ionic nature of the product, almost constant viscosity is maintained in the pH range of 3-10. The optimum pH range for hydration of Edicol® is 5.5-6 5.

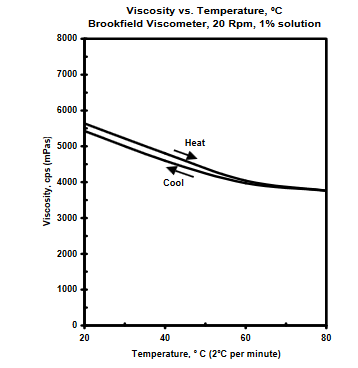

- The viscosities of aqueous Edicol® dispersions are not significantly affected by temperature. Hydration rates (rate of viscosity development) are influenced by short term heating. Edicol® will reach peak viscosities faster if the dispersion is heated to about 40ºC for short while. Beyond 40ºC and upto 80ºC, viscosities will decrease, but will recover on cooling, though this depends upon the holding time at the high temperature and the pH. For example, Edicol® solutions having a pH of 4-9 exhibit good thermal stability when heated to 80ºC and held for two hours and cooled again, but will thin irreversibly if the pH is held during this period at 3. Under normal conditions, Edicol® exhibits excellent freeze-thaw stability with insignificant syneresis in food products. Rheological properties of end products with Edicol® remain stable when refrigerated, stored at room temperatures or heated.

- Since Edicol® is non-ionic, good electrolyte compatibility is achieved over a broad ionic strength range. Very high concentrations of multivalent salts will affect hydration and may produce gels. Addition of other solids to Edicol® dispersions will affect the rheological behavior of the dispersion due to the competition for water between Edicol® and the other solids. The change in Edicol® dispersion behavior is affected by the concentration of other dissolved solids, but also whether such solids are added to the dispersion before, after or with Edicol® to the aqueous phase.

- Edicol® solutions will tolerate only small amounts of organic solvents. The polymer will precipitate out of solution and viscosities will reduce sharply when the weight % organic solvent in solution exceeds levels of 5%-10%.

- Edicol® is compatible with other gums, starches, hydrocolloids and gelling agents both natural and synthetic, normally used in foods, pet foods and feeds. Excellent viscosity synergism is achieved, without gel formation, with Xanthan gum in ratios of 50:50 to 90:10 (Edicol®: Xanthan). Unique stabilizer blends, both cost effective and functional can be achieved by combination of Edicol® with other hydrocolloids, gelling agents and emulsifiers to achieve the right mouth-feel and texture in the final food product.

- Like most natural galactomannans, Edicol® solutions are subject to degradation by microbial attack and hydrolysis. GRAS preservatives may be added to Edicol® solutions to extend solution shelf- life. Due to its high microbial purity, Edicol® has a long shelf- life in its dry form.

- Edicol® Guar Gums are available in a variety of viscosities, particle size distributions and hydration rates to suit every need. Detailed specification sheets are available on request. Specialized "tailor - made" products are possible.

- Edicol® are high purity Guar gums manufactured under strict hygienic condition and GMP’s. The manufacturing process from raw material to finished goods is fully automatic, incorporating complex pneumatic conveying and material handling system. Various safety features and HACCP during manufacturing and packaging ensure that Edicol® is free from foreign matter and impurities.

- Average standardized / blended batch sizes rang from 5,000 to 8,000 kilos (11,000 to 17,5000 Ibs), thus ensuring consistency and reproducibility from batch-to-batch. Every batch shipped to customers carries a certificate of analysis, including microbiological certification by our in-house microbiological quality control laboratories. Our well-equipped labs are capable of carrying out various tests and analytical procedures. No preservatives are added to Edicol®, including GRAS preservatives.

- Edicol® must be stored in a cool, dry place, away from heat and out of the sun. It is recommended to use all the contents from a Edicol® bag/ container, within a reasonable time, once opened. Due to the hygroscopic nature of the product, excessive humidity may lead to absorption of moisture and consequent microbial degradation if bags/ containers are left in an open state for long periods.

- In order to obtain lump-free, homogeneous solutions and aid dispersion, Edicol® should be dry blended with other ingredients used, such as sugar, starches etc. Such a pre-blend should be added to the vortex created by an agitator.

- Edicol® may also be slurried in certain miscible non-aqueous liquids (alcohol’s, glycol’s etc.) and poured into agitated water.

- Eductor systems may be used to make stock solutions, but care must be taken to pre-blend relatively free-flowing materials with Edicol® to aid in having a controlled and even rate of discharge form hoppers etc. On its own, Edicol® may have a tendency to bridge or form “rat-holes” in hoppers and bins.

- A high-speed mixing device is recommended to make Edicol® solutions. This ensures no formation of lumps, faster hydration and more homogeneous solutions. A holding period of upto 24 hours ensures that Edicol® solutions have completely hydrated and reached their peak viscosities. Heat upto 50ºC may be employed through a jacketed vessel to speed up the rate of Edicol® hydration in water.

Packaging & Availability

- Packaging Type

- Availability

Edicol® is available in 25 kgs or 50 lbs net, multi-wall paper (open mouth or valve filled) bags with a suitable liner or coated paper as a moisture barrier.