Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Attributes

- Provides excellent EMI/RFI shielding over a broad range of frequencies

- Non-flammable and no noxious odors

- Ships as a non-DG by air

- Low VOC content

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Clean-up

- Clean the spray system and equipment with tap water after use.

- Selective Coating

- For higher volume applications, paint can be applied via selective coating equipment. Use a system with constant fluid recirculation to keep the particles from settling in the lines. A fluid nozzle ranging from 1.2 mm –1.4 mm diameter and 5–10 psi fluid pressure is recommended depending on nozzle size.

- Manual Spray Guns

Use a standard fluid nozzle gun to spray the paint. The settings listed below are recommendations; however, performance will vary with different brands:

LVMP HVLP Nozzle tip diameter 1.2–1.4 mm 1.2–1.4 mm Inlet pressure 5–15 psi 5–15 psi Air flow 10–15 SCFM 8.3 SCFM Air cap 5–10 psi 5–10 psi - Recommended Preparation

- Plastic—Clean the substrate with Isopropyl Alcohol, MG #824, so the surface is free of oils, dust, and other residues. Drywall—For new drywall, apply directly on top of the drywall primer, after the primer has properly cured. When applying on top of existing paint, first wash the wall with a solution of T.S.P. diluted with water at a 1:10 ratio, to ensure good adhesion.

- Paint Roller

- This product may be applied with a standard paint roller. Thinning is not required.

Properties

- Physical Properties

- Typical Properties

- Cured Properties

- Uncured Properties

- Cure Instructions

- Allow to dry at room temperature for 24 hours, or after letting sit for 20 minutes, cure the paint in an oven for 3 hours @ 65 ˚C.

| Value | Units | Test Method / Conditions | |

| Density | 1.5 | g/mL | — |

| Value | Units | Test Method / Conditions | |

| Calculated VOC | 37 | g/L | — |

| Cure Times (at 22 ˚C) | 24 | Hours | — |

| Cure Times (at 65 ˚C) | 3 | Hours | — |

| Minimum Film Thickness | 15 | μm | — |

| Recoat Time (Drywall) | 5 | Minutes | — |

| Recoat Time (Plastic) | 20 | Minutes | — |

| Recommended Film Thickness | 25 | μm | — |

| Theoretical Coverage (at 2 mil, based on 100% transfer efficiency) | 32665 | cm2/L | — |

| Viscosity (at 25 ˚C) | 195 | cP | — |

| Value | Units | Test Method / Conditions | |

| Resistivity | 7.5 x 10⁻⁵ | Ω·cm | — |

| Salt Fog (at 35 °C, 95 °F, 96 h) | Excellent | — | — |

| Service Temperature Range | -40 to 120 | ˚C | — |

| Surface Resistance (at 50 μm) | 0.002 | Ω/sq | — |

| Value | Units | Test Method / Conditions | |

| Solids Content | 60 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

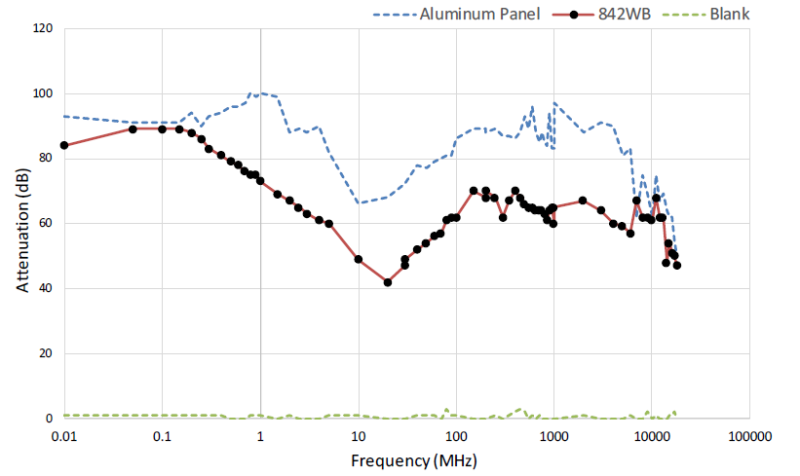

- Shielding Attenuation

Test performed with a two-coat thickness.

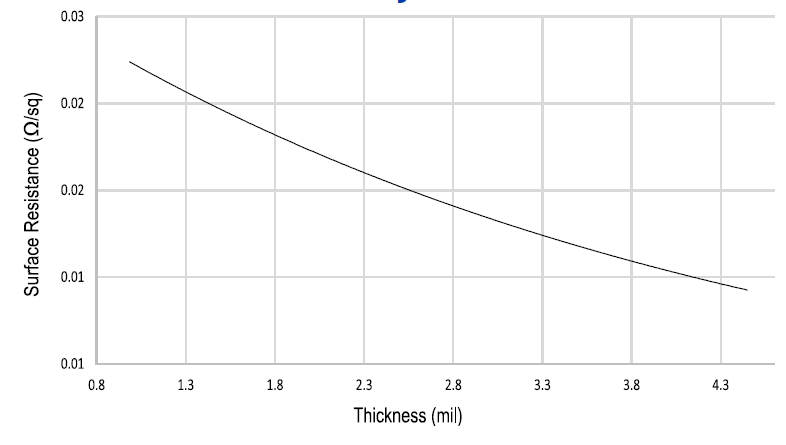

Test performed with a two-coat thickness.Surface Resistance by Paint Thickness

Packaging & Availability

- Available Packaging

Cat. No. Packaging Net Vol. Net Wt. 842WB-15ML Jar 12 mL 17.9 g 842WB-150ML Bottle 150 mL 224 g 842WB-850ML Can 850 mL 1.27 kg 842WB-3.78L Can 3.60 L 5.39 kg

Storage & Handling

- Shelf Life

- 3 Years

- Storage and Handling

- Store between 16 and 27 ˚C in a dry area, away from sunlight (see SDS). If exposed to freezing temperatures during storage or transport, keep product at room temperature for at least two days and ensure it is fully homogeneous prior to use.