Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

- 2:1 mix ratio

- 45 minute working time

- 24 hour cure at room temperature

- Constant service temperature of -50 to 120 °C

- Low exotherm

- Excellent dielectric properties

- Recommended Preparation

- Clean the substrate with Isopropyl Alcohol, MG #824, so the surface is free of oils, dust, and other residues.

Applications & Uses

- Applications

Properties

- Typical Properties

- Cured Properties

- Uncured Properties

- Water Absorption

Approximate sample size: 12.8 mm width, 12.5 mm thickness, and 4.8 g. Cured 1 hour @ 65 ˚C.

1 Week 2 Weeks 4 Weeks Water 0% 0.1% 1.4% Salt Water 10% 0.08% 0.3% 0.5% - Note

- *Based on 100 g sample. Varies by volume and geometry.

- Cure Instructions

Allow to cure at room temperature for 24 hours, or cure in an oven at one of these time/temperature options:

Temperature 65 °C 80 °C Time 1 h 45 min Moisture contamination with polyurethanes can create large bubbles on the surface and a lumpy appearance. For consistent curing results, ensure that the resin (part A) is dry before use and the mixture is kept dry during cure. If moisture contamination of part A is suspected, follow the steps below:

- Pre-heat part A at 65 °C for 2 hours. Mix the heated resin with the appropriate amount of hardener (do not allow the resin to cool as this may create condensation that wets the resin).

- Mix the 2 components together and cure in an enclosure that has a constant stream of nitrogen gas flowing through to keep the environment dry.

| Value | Units | Test Method / Conditions | |

| Mix Ratio | 2:1 | Volume | — |

| Mix Ratio | 1.7:1 | Weight | — |

| Working Time | 45 | minute | — |

| Value | Units | Test Method / Conditions | |

| Breakdown Voltage | 50900 | V | — |

| Compressive Strength | 253 | N/mm2 | — |

| CTE (After Tg) | 210 | ppm/˚C | — |

| CTE (Prior Tg) | 83 | ppm/˚C | — |

| Dielectric Strength | 407 | V/mil | — |

| Glass Transition Temperature (Tg) | 44 | °C | — |

| Hardness D | 80 | — | — |

| Intermittent Temperature | 130 | ˚C | — |

| Lap Shear (Aluminum) | 7.5 | N/mm2 | — |

| Lap Shear (Stainless Steel) | 4.9 | N/mm2 | — |

| Resistivity | 1.9 x 10¹³ | Ω·cm | — |

| Service Temperature Range | -50 to 120 | ˚C | — |

| Tensile Strength | 10 | N/mm2 | — |

| Thermal Conductivity (at 25˚C) | 0.3 | W/(m·K) | — |

| Value | Units | Test Method / Conditions | |

| Mixed Density | 1.1 | g/mL | — |

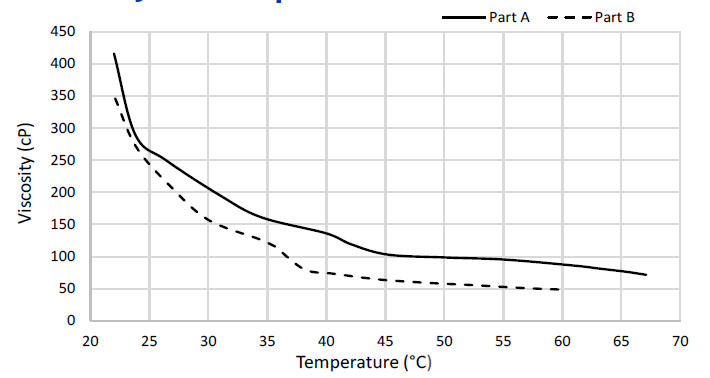

| Viscosity (at 25 ˚C) ⁽ᵇ⁾ | 220 | cP | — |

| Viscosity (at 25 ˚C) ⁽ᵃ⁾ | 320 | cP | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Mixing

- (Optional) Pre-heat part A to improve surface quality.

- Scrape settled material free from the bottom and sides of the part A container; stir the contents until homogenous.

- Measure 2 parts by volume of the pre-stirred part A, and pour into the mixing container. Ensure all contents are transferred by scraping the container.

- Measure 1 part by volume of the part B, and pour into the mixing container. Ensure all contents are transferred by scraping the container

- Thoroughly mix parts A and B together.

- (Optional) Put in a vacuum chamber at 25 inHg.

- Pour the mixture into a container holding the components to be protected.

- Blanket both parts with nitrogen if the material is not used up to prevent moisture.

- Close the part A and B containers tightly between uses.

Mixing >500 g at a time decreases working life and can lead to a flash cure. Limit the size of hand-mixed batches. For large production volumes, contact MG Chemicals Technical Support for assistance.

- Viscosity vs. Temperature

Packaging & Availability

- Available Packaging

Cat. No. Packaging Net Vol. Net Wt. 8810-375ML 2 Bottle kit 375 mL 428 g 8810-2.55L 3 Can kit 2.55 L 2.91 kg 8810-60L 3 Pail kit 60 L 68.6 kg

Storage & Handling

- Shelf Life

- 2 Years

- Storage and Handling

- Store between 16 and 30 ˚C in a dry area, away from sunlight (see SDS). Minimize the time that the container is kept opened and purge with nitrogen before closing if the material is not used up at once.