Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Typical Properties

- Note

- ¹ Measured with Melt Indexer

- ² Measured with DSC, both heating and cooling speeds of 10°C/min

- ³ Measured with Micromeritics Gas Pycnometer at 23°C

- * The above figures are representative values and are not guaranteed.

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (190°C, 2160g)¹ | max. 5 | g/10min | — |

| Melting Point ² | 120 | °C | — |

| Glass Transition Temperature (Tg) ² | 29 | °C | — |

| Crystallization Temperature ² | 74 | °C | — |

| Density ³ | 1.22 | g/cm³ | — |

Regulatory & Compliance

Technical Details & Test Data

- Example of Processing

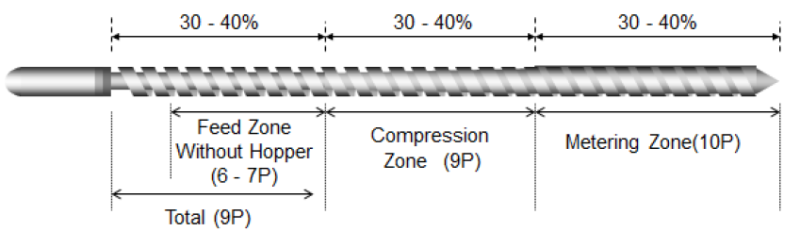

Recommendable Screw Design:

(a) L/D of Extruder: 24 - 30

(b) Screw Design: Full - flight type is recommendableUnnecessary mixing may generate gels

Too long feed-section cannot discharge the gas to air

(c) Compression Ratio: 3.0 - 3.5

- Too small C.R. causes insufficient melting.

- Too large C.R. causes excessive heat-generated.

(d) Plating

- Chrome Plating ; Easy and Reasonable

- Nickel Alloy Plating ; Flat Surface, but High Cost

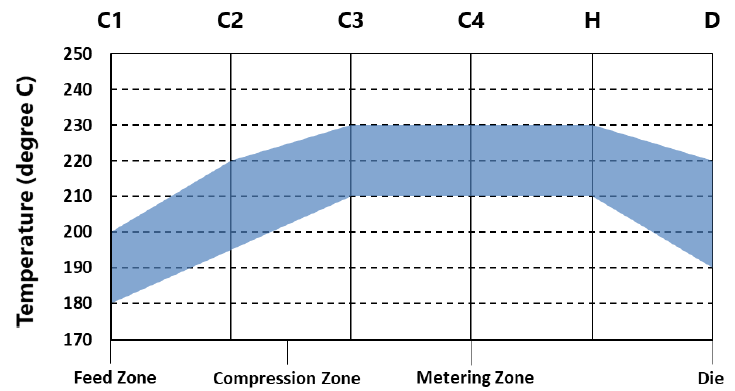

Processing Temperature:

Notes:BTR8002P extrusion temperature is recommended to be at least at 210°C or above. Lower temperature profile may cause worse film appearance.

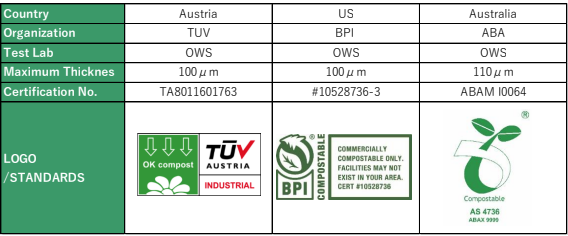

- Compostability

BTR8002P is certified with the following regulation.

Storage & Handling

- Storage Condition

It is recommended to store BTR8002P at as low temperature below 5°C as possible because there is a risk of the MFR rapid increasing and/or decreasing over time in case it is stored at over 5°C. It is also recommended to seal the bag as soon as possible after opening and/or using to prevent moisture absorption of pellet. The moisture absorption of pellet may lead to MFR rapid increasing over time.

BTR8002P is intended for indirect food contact only. Quality assurance and hygiene for cosmetics and pharmaceutical applications are not considered.

BTR8002P would be ignited by heat storage if BTR8002P is kept high temperature for a long time. When storing or disposing of the molded BTR8002P, please kindly cool it to 50°C or less.