Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Food Ingredients Functions

- Technologies

Features & Benefits

- Labeling Claims

- Food Ingredients Features

- Product Features

- Excellent texture, color and volume.

- Consistency is greatly improved due to improved dough tolerance.

- Excellent fresh keeping qualities and buns have "short eating" qualities.

- For steam buns, works well in both chilled and frozen.

- Compensation for variations in raw materials (e.g., flour quality).

- Improved dough machinability by gluten complexing.

- Good fermentation tolerance, ability to correct dough fermentation mistakes.

- Greater tolerance to production abuse of dough by providing a drier, less sticky dough. This reduces tearing and facilitates processing.

- Improved hydration rate of the flour and other ingredients.

- Improved finished bun characteristics:

- Finer crumb grain.

- Silkier, smoother texture.

- Moist and pleasant mouthfeel.

- Frozen and chilled steam bun.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Formulation Considerations

- Dough conditioners - No additional emulsifiers are needed. MASEMUL® EB 1006 is specially developed to be full solution.

- Yeast - Addition of extra yeast, 1.0-1.5% when the blends used for other type of flour type is changed to whole meal.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Outcome and Results

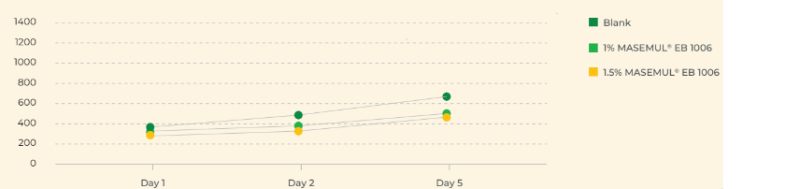

By using this MASEMUL® EB 1006, volume, softness, cell structure, shelf life and eating parameters are similar to any other type of process in baked or steamed bun.

Chinese Steam Bun with MASEMUL® EB 1006

Baked Bun:

Days Blank 1% MASEMUL® EB 1006 Day 1 386.5 346.6 316.6 Day 2 441.6 395.4 356.6 Day 5 652.4 510.3 471.3 Change in hardness of breads with different dosage MASEMUL® EB 1006 over storage periods of 5 days