Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Fluids & Lubricants Functions

- Industrial Additives Functions

Features & Benefits

- Fluids & Lubricants Features

- Industrial Additives Features

- Product Features

Low foaming extreme pressure lubricant.

Applications & Uses

- Markets

- Applications

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Applications

- Lubricants

- Corrosion inhibitors

- Detergents

- Metalworking fluids and wetting agents

Properties

- Physical Form

- Appearance

- Clear to yellow liquid

- Dispersible in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Activity | 95.0 | % | — |

| Flash Point | min. 212 | °F | — |

| Pour Point | 15.0 | ºC | — |

| Acid Number (1ˢᵗ infl.) | 190.0 - 210.0 | — | BRI-PEACID |

| Phosphoric Acid | max. 3 | % | BRI-PEACID |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Performance Data

- Foaming test:

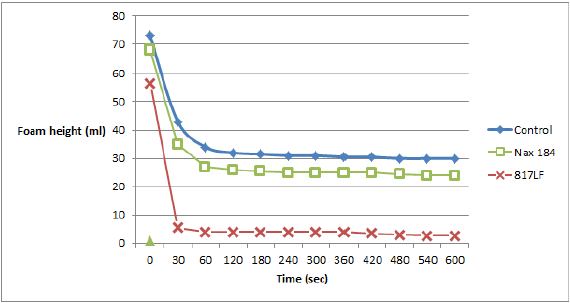

As the graph llustrates, Naxonac 817LF has the best low foaming ability compared to the Control (a well-known metalworking fluids additive) and our other metalworking phosphate ester additives (Naxonac® 184). The low foaming trend was similar in different types of metalworking fluid formulations. The foam test was carried out at 0.125% concentration (neat ester) or 5% as metalworking fluid formulation. This is a hand shake foam test where the foam height is measured over 10 min.

Figure 1: Foam test result for Naxonac® 817LF

- Iron chip corrosion test:

MWF formulations containing Naxonac® 817LF behaved the same as other phosphate ester based metalworking fluid. Their formulations passed the 24hr iron chip corrosion test (ASTM D4627) in soluble oil, semi synthetic and synthetic metalworking fluid (MWF) formulations at 5% concentration in 100ppm hard water.

- Aluminum corrosion test:

This product also showed no aluminum staining in a 24 hour period in most metalworking formulations at 5% concentration in the pH range of 8.8-9.2 at room temperature.

- Lubricity test:

The lubricity test was obtained from testing on a Microtap Tauro 120T instrument on aluminum 6061-T6. This test measures the average torque over the specified portion of the metal cut. The lower the torque, the better the metalworking formulation; which generally means the higher the efficiency of the additive in the formulation. Naxonac® 817LF was tested against the Control (a commercial product) and Naxonac® 184 in soluble oil, semi-synthetic and synthetic metalworking formulas. The results of the testing done at 5% concentrations are presented below.

Packaging & Availability

- Packaging Type

- Packaging Information

- 55 gallon drum

- 275 gallon tote

Storage & Handling

- Storage Information

Store covered in a dry, well ventilated area. Keep container tightly closed when not in use. Prevent from freezing. Store material above 20ºC.