Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Features

• Versatile, high-strength prepreg system

• Curable at temperatures as low as 80°C (176°F)

• Can be processed with vacuum-only processing

• Suitable tack for most hand layup and automated placement

• Low viscnsity — Ideal for prepreg from 30 to 3Wgsm

• Lloyd's Register Certified

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Purpose

ThinPreg 736LT is commonly used in vacuum bagging, autoclave processes and could be applied to other pressure molding processes.

ThinPreg 736LT is a controlled viscosity system especially suitable for low-flow processing conditions (vacuum bag pressure and minimum cure temperature). ThinPreg 736LT has a very high compressive and interlaminar shear strength. It's suitable for both light weight panels and heavily loaded components for example in high end marine applications.

ThinPreg 736LT can be used for sandwich structures with honeycomb, foam and balsa cores, in conjunction with NTPT's GF736 Adhesive Film or for monolithic parts. NTPT prepreg products are often used with automated tape laying machines (ATL). Our products are formatted.

Regulatory & Compliance

- Quality Standards

Technical Details & Test Data

- Rheology

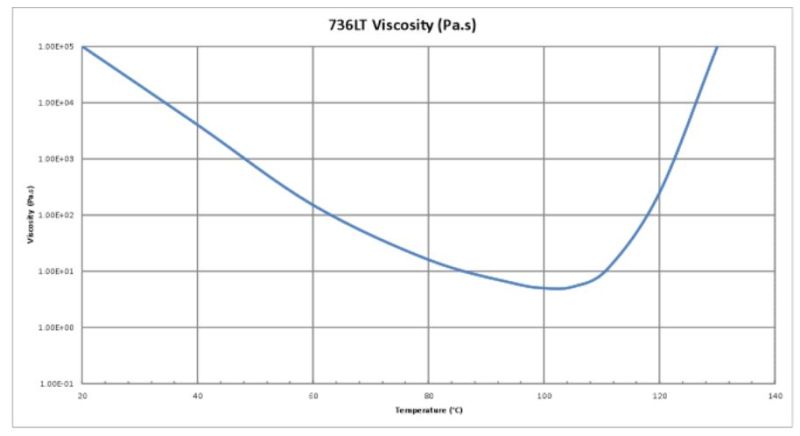

ThinPreg™ 736LT resin viscosity profile conducted at 1°C/minute (1.8°F/minute).

Minimum viscosity: 5Pa.s at 100°C (212°F).

Minimum viscosity: 5Pa.s at 100°C (212°F).- Instructions for use

Cure cycles

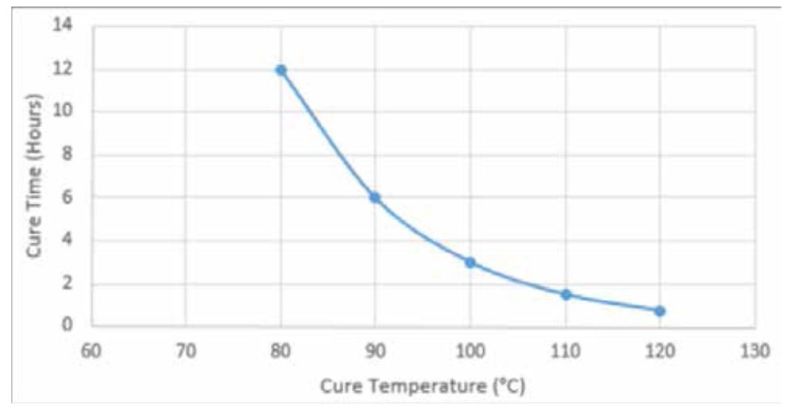

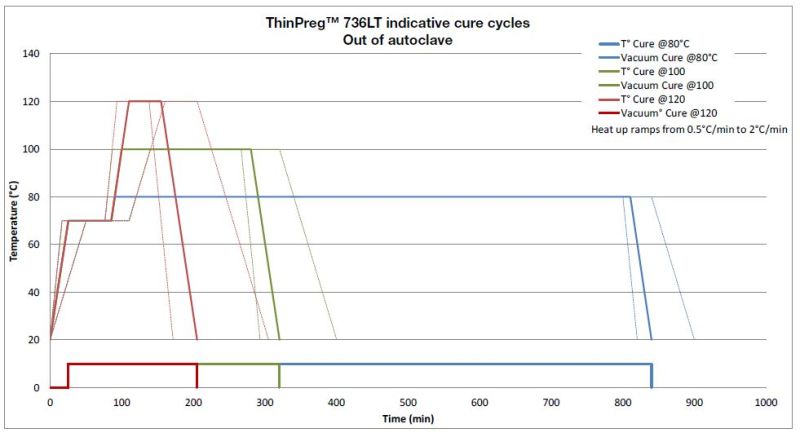

For a good balance of composite properties, the laminate can be cured at 80°C (176°F) for a minimum of 12 hours.ThinPreg™ 736LT may be cured at higher temperatures for a shorter time. At a cure temperature of 100°C (212°F) cure can be achieved in 3 hours or at 120°C (250°F) cure can be achieved in 45 minutes.

A laminate may be cured in stages if, for example, making a cored component. However, in a two stage cure, a minimum of 4 hours at 85°C (185°F) or 5 hours at 80°C (176°F) is recommended before debagging a skin, and it must be ensured that this skin is cured for the equivalent of at least 10 hours at 85°C (185°F) or 12 hours at 80°C

A laminate may be cured in stages if, for example, making a cored component. However, in a two stage cure, a minimum of 4 hours at 85°C (185°F) or 5 hours at 80°C (176°F) is recommended before debagging a skin, and it must be ensured that this skin is cured for the equivalent of at least 10 hours at 85°C (185°F) or 12 hours at 80°C

(176°F) before going into service. NTPT does not recommend curing ThinPreg™ 736LT under vacuum pressures of less than 0.85 bars. If a ramp rate of less than 0.3°C/min (0.5°F/min) is used, users should satisfy themselves that this allows adequate flow.

NTPT does not recommend curing ThinPreg™ 736LT under vacuum pressures of less than 0.85 bars. If a ramp rate of less than 0.3°C/min (0.5°F/min) is used, users should satisfy themselves that this allows adequate flow.A one hour dwell plateau at 70°C (158°F) with full vacuum pressure is recommended for air removal before going to full curing temperature.

Curing at 80°C: When curing at 80°C (176°F) it is important to ensure the temperature is monitored off the trailing thermocouple. 80°C (176°F) should be treated as the minimum cure temperature for 736LT; 70-75°C (158-167°F) will not generate adequate mechanical properties.

Material preparation:

When preparing the lay-up the prepreg should be removed from the freezer and allowed to thaw in a sealed bag. This may take 6 to 24 hours depending on roll size. This prevents atmospheric moisture from condensing on the prepreg which may cause voiding on cure. The mold surface should be release coated and must have been

tested for vacuum integrity prior to lay-up.Thin laminates:

When using very thin laminates (e.g. with a total laminate fiber weight of less than 300gm²), care needs to be taken to avoid extracting excessive amounts of resin during the cure process. To avoid this, a microporous release film can be used, and for particularly critical components, a prepreg peel ply should be used.

Safety & Health

- Health and safety

ThinPreg™ 736LT contains epoxy resins which can cause allergic reaction. When uncured, ThinPreg™ 736LT should be handled with appropriate gloves. When cured, a composite laminate made of ThinPreg™ 736LT should be cut, drilled or machined in a room equipped with an exhaust ventilation and filtration system, by operators wearing protective clothing and masks.

Packaging & Availability

- Product Format

ThinPreg™ 736LT Product Format Hand layup ATL Paper YES YES Polythene film YES NO Width (mm) 400 300 Available FAW (gsm) Custom 50 75 100 150 200 250 300

Storage & Handling

- Storage

Storage Temperature Value Unit -18°C 0°F 24 Months +18-22°C +64-72°C 60 days All prepreg materials should be stored in a freezer when not in use to maximize their useable life, since the low temperature reduces the reaction of resin and catalyst to virtually zero. However, even at -18°C (0°F), the temperature of most freezers, some reaction will still occur. In most cases after some years, the material will become unworkable.

When not in use ThinPreg™ 736LT products should be maintained at -18°C (0°F). To avoid condensation on their surfaces, allow rolls to reach room temperature before unwrapping.