Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

- Adhesion to a wide variety of substrates

- Full cure at room temperature

- Easy to apply

- Fast setting

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Cure Method

- Surface Preparation

Surfaces should be clean, dry and grease-free before applying the adhesive. Use a suitable solvent (such as acetone or isopropanol) for the degreasing of surfaces. Some metals such as aluminum, copper and its alloys will benefit from light abrasion with emery cloth (or similar), to remove the oxide layer.

- Directions for Use

1. Dual cartridges:

a) Insert the cartridge into the application gun and guide the plunger into the cartridge.

b) Remove the cartridge cap and dispense material until both sides are flowing.

c) Attach the static mixer to the end of the cartridge and begin dispensing the material.

2. Apply material to one of the substrates.

3. Join the parts. Parts must be joined within 3-4 minutes of mixing the two epoxy components.

4. Large quantities and/or higher temperature will decrease the usable life or pot life.

5. Apply pressure to the assembly by clamping for 8 minutes or until handling strength is obtained.

6. Full cure will be obtained after 24 hours at 25°C (77°F). Heat can be used to accelerate the curing process.

NB. Exercise caution when mixing large quantities due to exothermic reaction.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Physical Properties of Uncured Adhesive

ET500A ET500B Chemical composition Epoxy Resin Amine Hardener Appearance Colorless Colorless Viscosity at 25°C 12,000-18,000 mPa.s (cP) 15,000-30,000 mPa.s (cP)

Specific gravity 1.2 1.1 - Typical Curing Properties

Mix ratio by volume 1:1 Maximum gap fill 2 mm 0.08 in Usable / pot life at 23°C 3-4 mins Handling time at 23°C 5-8 mins Working strength at 23°C 30-60 mins Full cure at 23°C 24 hours - Typical Performance of Cured Adhesive

Shear strength (mild steel)* (ISO4587) 12-18 N/mm² (1700 - 2600 psi) Peel strength (aluminum) (ISO4578) 5-20 N/25mm (1-4 PIW) Hardness (ISO868) 70-80 Shore D Elongation at break (ISO37) <5% Glass transition temperature Tg 40-50°C (104-122°F) Dielectric strength 15-25 kV/ mm Thermal conductivity 0.22 W/(m.K) Water absorbtion (ISO62) 0.75% (24 hrs submersion at 23°C) - Strength Development

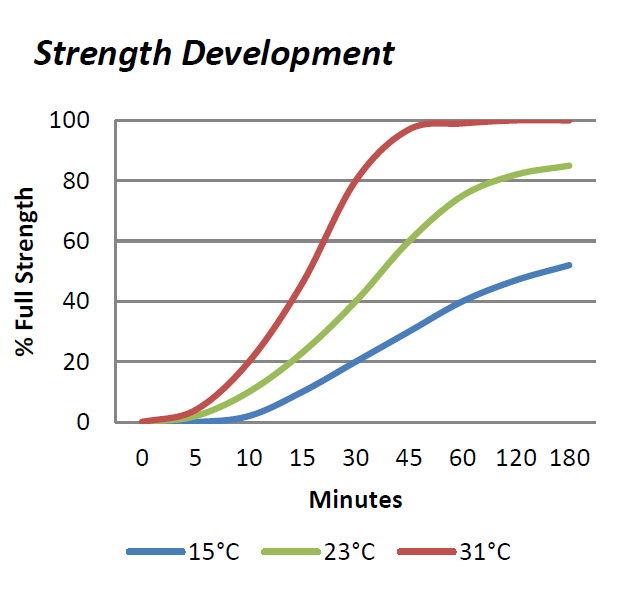

Graph shows typical strength development of bonded components. An increase of 8°C in temperature will halve the cure time. Lower temperatures will result in a slower cure time.

- Hot Strength

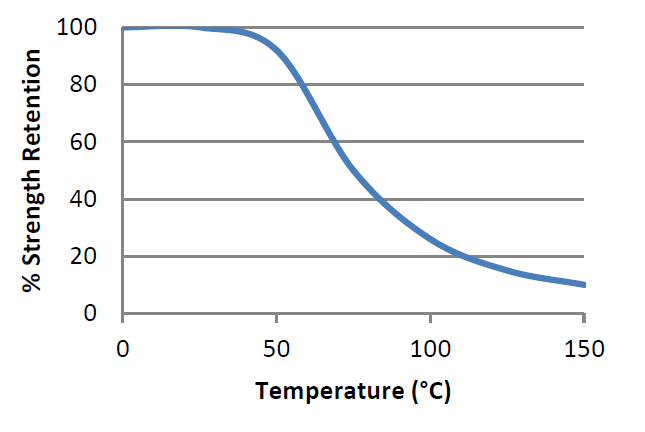

“Hot strength” shear strength tests performed on mild steel. Fully cured specimens conditioned to pull temperature for 30 minutes before testing at temperature.

ET500 can withstand higher temperatures for brief periods (such as for paint baking and wave soldering processes) providing the joint is not unduly stressed. The minimum temperature the cured adhesive can be exposed to is -40°C (-40°F) depending on the materials being bonded.

Storage & Handling

- Storage Temperature

5 to 25°C (41 to 77°F)