Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

- Adhesion to a wide variety of substrates

- Cures at room temperature

- Easy 1:1 mix ratio by volume

- Good resistance to impact and vibration

- Thixotropic, non-slump rheology

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Cure Method

- Additional Information

This product is not recommended for use in contact with strong oxidizing materials. This product may affect some thermoplastics and users must check compatibility of the product with such substrates.

Information regarding the safe handling of this material may be obtained from the Safety Data Sheet.

Users are reminded that all materials, whether innocuous or not, should be handled in accordance with the principles of good industrial hygiene.- Surface Preparation

Surfaces should be clean, dry and grease-free before applying the adhesive. Permabond Cleaner A is recommended for the degreasing of most surfaces. Some metals such as aluminum, copper and its alloys will benefit from light abrasion with emery cloth (or similar), to remove the oxide layer.

- Directions for Use

- Surfaces must be clean, dry and grease-free prior to bonding.

- Shake cartridge (or stir bulk material) before use if separation has occurred.

- Apply a thin bead of adhesive pre-mixed through a static mixer nozzle. (Alternatively bulk material can be dispensed via metered dispensing equipment).

- Assemble components and clamp.

- Maintain pressure until handling strength is achieved.

- Allow 4-5 days for adhesive to fully cure. Accelerated cure times may be achieved by heating.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Physical Properties of Uncured Adhesive

PT321 A PT321 B Chemical composition Polyurethane Isocyanate Appearance Black Cream Viscosity at 25°C 4000-8000 mPa.s (cP)

Thixotropic3000-6000 mPa.s (cP)

ThixotropicSpecific gravity 1.25 1.45 - Typical Curing Properties

Ratio of use 1 : 1 by volume Maximum gap fill 5 mm (0.2 in) Pot life 15-20 minutes Handling time (steel) ISO4587

(0.3 N/mm² shear strength is achieved)90-120 minutes Full cure at 23°C: 4-5 days

at 90°C: 30 minutes- Typical Performance of Cured Adhesive

Shear strength* (ISO4587) Zinc: 5-6 MPa (700-900 psi)

Steel: 12-18 MPa (1700-2600psi)

FRP Glass Epoxy: 5-7 N/mm² (700-1000psi)

FRP Glass Polyester: 12-14 N/mm² (1700-2000psi)

Carbon Fiber: 9-11 N/mm² (1300-1600psi)Tensile strength

ISO 3715-20 MPa (2200-2900 psi) Elongation at break

ISO 37<20% Hardness

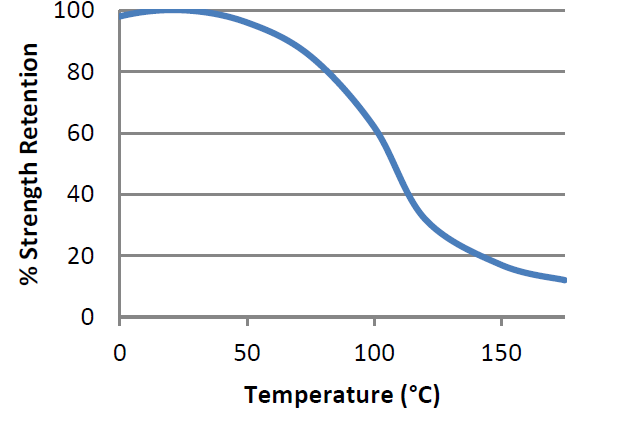

ISO 86860-75 Shore D Coefficient of thermal expansion (ASTM D-696) 85 x 10-6 1/K - Hot Strength

“Hot strength” shear strength tests performed on mild steel. Product fully cured at room temperature and conditioned to pull temperature for 30 minutes before testing.

“Hot strength” shear strength tests performed on mild steel. Product fully cured at room temperature and conditioned to pull temperature for 30 minutes before testing.

PT328 can withstand higher temperatures for brief periods providing the joint is not unduly stressed. The minimum temperature the cured adhesive can be exposed to is -40°C (-40°F) depending on the materials being bonded.

Packaging & Availability

- Other Products Available

Anaerobics

- Thread lockers

- Thread sealants

- Gasket makers

- Sealants / retainers

Cyanoacrylates

- Instant adhesives

- For rapid bonding of metals, plastics, rubber and many other materials

Epoxies

- Two-part room temperature cure adhesives

- Single-part heat cure adhesives

- Modified Technology (MT) flexible grades available

MS-Polymers

- Single-part, moisture-curing, flexible sealants

Polyurethanes

- Two-part room temperature curing adhesives

Toughened Acrylics

- Rapid curing, high strength structural adhesives

UV Light Cured Adhesives

- Glass / plastic bonding

- Optically clear

- Non-yellowing