Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

- Adhesion to a wide variety of substrates

- Fast cure at room temperature

- No mix application

- High shear and peel strength

- Good impact strength

- High temperature resistance

Applications & Uses

- Markets

- Cure Method

- Additional Information

This product is not recommended for use in contact with strong oxidizing materials. This product may affect some thermoplastics and users must check compatibility of the product with such substrates.

Information regarding the safe handling of this material may be obtained from the Safety Data Sheet.

Users are reminded that all materials, whether innocuous or not, should be handled in accordance with the principles of good industrial hygiene.- Surface Preparation

Surfaces should be clean, dry and grease-free before applying the adhesive. Permabond Cleaner A is recommended for the degreasing of most surfaces. Some metals such as aluminum, copper and its alloys will benefit from light abrasion with emery cloth (or similar), to remove the oxide layer.

- Directions for Use

- Surfaces must be clean, dry and grease-free. Apply Initiator 41 to one surface (if using initiator to reduce cure time).

- Apply adhesive to the other surface.

- Assemble the components using sufficient force to spread the adhesive thinly. Parts should be bonded immediately and within a maximum of two hours of applying the Initiator.

- Maintain pressure until handling strength is achieved. The time required will vary according to the joint design, gap and surfaces being bonded.

- Allow 24 hours for adhesive to fully cure. Accelerated cure times may be achieved by heating.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Physical Properties of Uncured Adhesive

Chemical composition Urethane methacrylate

Appearance Orange/red viscous liquid

Viscosity at 25°C 20rpm: 25,000 – 50,000 mPa.s (cP)

2.5rpm: 90,000 – 150,000 mPa.s (cP)Specific gravity 1.1 - Typical Curing Properties

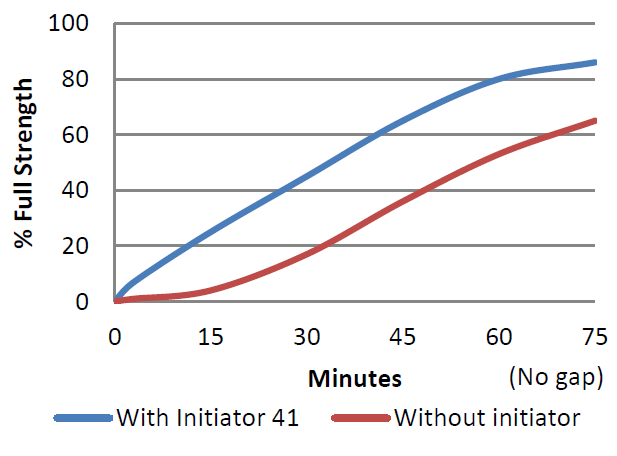

Maximum gap fill 0.5 mm (0.02 in) Fixture time (zinc) at 23°C* 5-10 mins (no initiator)

20-30 secs (with Initiator 41)Handling time (zinc)* 15-20 mins (no initiator)

1-3 mins (with Initiator 41)(0.3 N/mm² shear strength is achieved) at 23°C

Working strength (zinc)* at 23°C60-120 mins (no initiator)

30-60 mins (with Initiator 41)Full cure at 23°C 24 hours - Typical Performance of Cured Adhesive

Shear strength (ISO4587)* Steel: 14-20 N/mm (2000-3000 psi)

Zinc: 10-15 N/mm (1450-2200 psi)Shear strength (steel to ferrite) using Initiator 41 After 3 minutes: 4 N/mm² (600 psi)

After 24 hours: >14 N/mm² (>2000 psi) (substrate failure)Peel strength (aluminum) (ISO 4578) 45-65 N/25mm (10-14 PIW) Tensile strength (ISO37) 30N/mm² (4350 psi) Impact strength (ASTM D-950) 10-15 kJ/m² Coefficient of thermal expansion (ASTM D-696) 80 x 10-6 1/K Thermal conductivity (ASTM C-177) 0.1 W/(m.K) Dielectric constant (ASTM D-150) 4.6 Dielectric strength (ASTM D-149) 30-50 kV/mm Volume resistivity (ASTM D-257) 2 x 1013 Ohm.cm - Environmental Resistance

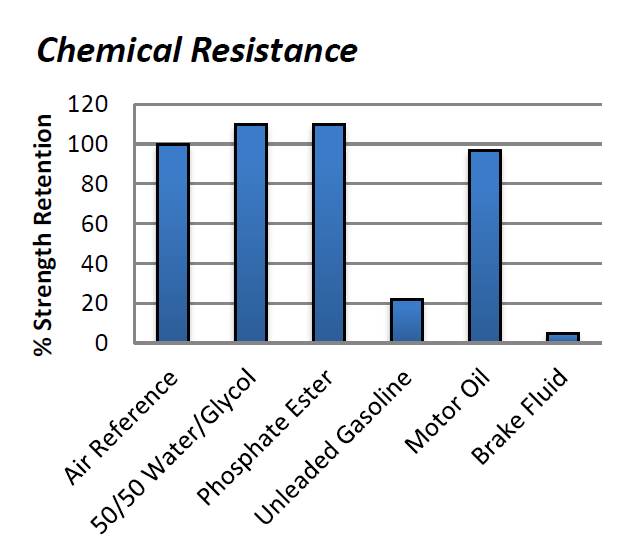

All values were generated on as received steel lap shears as described in ISO4587. Adhesive was cured at room temperature for 48 hours prior to environmental exposure. Test pieces were assembled with no induced gap and subjected to continuous exposure for 1000 hours at the testing temperature and then the shear strength was tested at room temperature.

1000 hours % strength retention 95°C 110% * 120°C 118% * 150°C 132% * 175°C 127% * 205°C 97% - Strength Development

Graph shows typical strength development of bonded components at 23°C. Curing at higher or lower temperatures may affect cure speed.

Graph shows typical strength development of bonded components at 23°C. Curing at higher or lower temperatures may affect cure speed.- Hot Strength

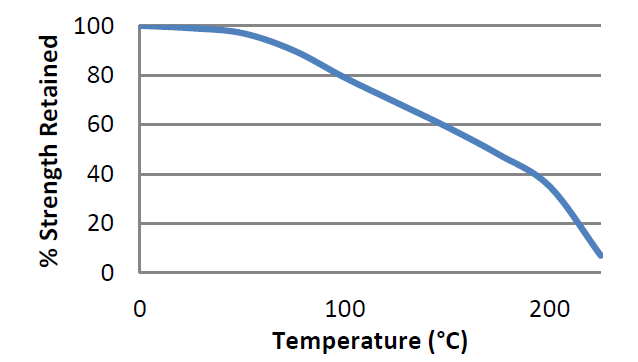

“Hot strength” shear strength tests performed on mild steel. Fully cured specimens conditioned to pull temperature for 30 minutes before testing at temperature.

TA437 can withstand higher temperatures for brief periods (such as for paint baking and wave soldering processes) providing the joint is not unduly stressed. The minimum temperature the cured adhesive can be exposed to is -55°C (-65°F) depending on the materials being bonded.- Chemical Resistance

Specimens were immersed for 30 days at 85ºC and tested at room temperature.