Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Characteristics

The products with 110MB80 are characterized by low density and low smoke generation. Polyolefin with 110MB80 will not lead to the phenomenon of water-sliding surface during the process of extrusion due to its ammonium polyphosphate- free system with higher thermal stability, excellent dispersion and good performance in flame retarding. 110MB80 is mainly used in polyolefin sheet material, glass fiber reinforced polypropylene, inner decoration materials and flame retarding materials for motor cars

- Advantages

- 110MB80 is halogen-free, low smoke, low toxicity and eco-friendly.

- For the high processing temperature of 110MB80, it will not lead to the phenomenon of water-slidingsurface.

- For its high content of phosphorus, 110MB80 has excellent performance in solid-phase flame retarding used in polyolefin product.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Recommanded Dosage

Resin PP PP+GF (15%) PP+GF (20%) PP+GF (25%) PP+LGF (40%) PP+LGF (50%) PP+LGF (60%)

Dosage of 110 MB80 % 30 30~32 30~32 ≥32 ~23 ~23 ~23 UL 94(1.5mm) V-0 Pass Pass Pass Pass LOI 35 29 29.5 30

Properties

- Flame Rating

- Physical Form

- Appearance

- White particle

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Particle size | 1.5 ~ 5.0 | mm | — |

| FR Content | Approx. 80 | %(w/w) | — |

| Density | 1.25 ~ 1.27 | g/cm3 | — |

| Water content | max. 0.5 | %(w/w) | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

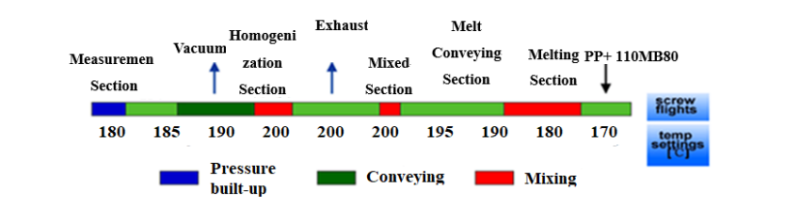

- Extrusion Process (Twin Screw Extruder)

Notes

- The decomposition temperature of 110MB80 in nitrogen is 280 ℃, thus the processing temperature of twin screw extruder can be adjusted higher accordingly. Sieves can be put on the head of machine. Maintaining vacuum of the twin screw extruder during the processing is also needed.

- The substances which affect flame retardant performance: phthalocyanine green that contains Cl-1 toner will make the flame retardant loss effect. Carbon black would have a bad effect on the flame retarding performance, so more flame retardant is required.

- Acid-resistant processing machines have to be used for extrusion and molding since 110MB80 is acidic in nature.

- 110MB80 work in non-fiber-reinforced system, adding anti-dripping agents could achieve better results.

Packaging & Availability

- Packaging

25kg/package.

Storage & Handling

- Storage

Transported as the common chemicals.