Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Info

As an electrical encapsulant /sealant B-4682 offers very high shock isolation and protection of sensitive electronics from loads derived from extreme thermal cycling, (- 65°C to 150°C)

as well as mechanical shock and vibration. B-4682 has been successful in military aircraft applications for sealing exterior electronic sensors.

B-4682 handles harsh environments and is particularly effective against moisture, salt water, acids, alkalies, oils, fuels and detergents. The highly flexible (200% elongation)

properties of B-4682 permits assembly of materials with extreme dissimilar thermal expansion properties to survive thermal cycling. Likewise mechanical vibration, shock

and impact are easily absorbed by B-4682.

B-4682 is particularly useful for assembly of low surface energy substrates such as Delrin to itself and an almost unlimited list of other materials, while offering an

excellent balance between material strength, peel, shear and tensile bond strengths, chemical resistance, and environmental resistance. This product works very well as a

waterblock sealant for cable and transducer terminations that withstands years of

submersion in deep-sea and other harsh chemical environments.

Operational temperatures are from -65°C to 150°C, above which it will soften considerably, but not flow as it is a crosslinked epoxy system. B-4682 is very easy to use with low HAZMAT impact as a 100% solids epoxy system— no plasticizers that bloom to the surface and no solvents causing VOC problems. The product is also availble in a thixotropic silcate filled version B-4682TH which can be applied to vertical surfaces without sagging, or in paste or electrically conductive form.

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Cure Method

- Curing Guide

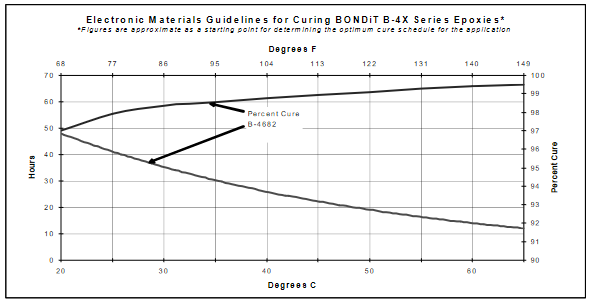

A wide range of curing regimes may be employed: ambient set in 6 hours, tack free in 20 hours, and 95% cure in 2 days; will cure 98% in 4 hours at 200°F.

Mix part A with part B, 1:1 ratio by volume or weight. Degassing is optional. Pot life is typically 90 minutes, at ambient temperature. Optional: Surface prep

by abrading or grit blasting substrates with #100 AlOx followed by degrease and/or alcohol wipe will increase adhesion. Apply B-4682 by roller or brush.- Electronic Encapsulant For Extreme Environments

This highly flexible potting material protects electronic sensors from high impact mechanical and thermal shock, and extreme thermal cycling and vibration with excellent chemical resistance

- Easy Use

Two-part, primerless, highly flexible epoxy, ambient and thermal cure. Low HAZMAT impact. Excellent sealant for electronic and electrical encapsulation for harsh environments.

- Harsh Environments

- "

Marine,Civil Engineering, Industrial, Downhole oil, Underwater, Mining, Industrial,, Automotive.

"

Technical Details & Test Data

- B-4X Series Epoxy Product Comparison Guide

Product Elongation Tensile Strength Durometer Key property B-4682 200% to

300%Low

Not prone to creep and

much stiffer compared

to B-46 while still elastic.45

A-ShoreHigh tack (but less compared to B-46),

bonds low surface energy substrates

without surface prep such as Delrin.

Very good shock resistance. Good

electrical properties. Suitable for very

low temperature adhesive and potting

applications- Bonds Dissimilar Materials

An adhesive for bonding un-treatedun-treatedun-treatedun-treatedun-treated dissimilar materials such as plastics including UHMW, HDPE, PP, PET, PEEK, PPS, PBT, Acetal, PTFE (Teflon), ETFE (Tefzel), PVC, PVCF, PVDF, ABS, ECTFE, polyamide, polyimide, rubber and urethane compounds on metal, glass, composites, cement, wood and celluose.

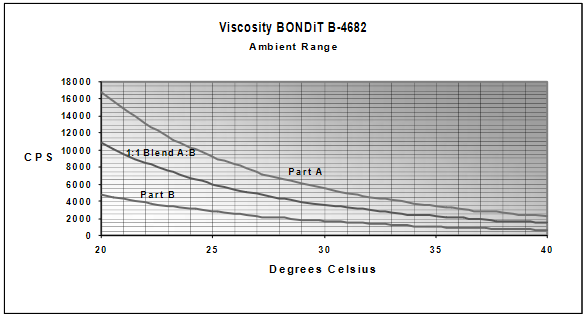

- Viscosity Bondit B-4682

Storage & Handling

- Storage

The usable shelf life of unopened containers of BONDiTTM B-4682 resin is one year, and should be stored in cool, dry place. When not in use, containers should be kept tightly closed. BONDiTTM B-4682 is available in side-by-side handheld and pneumatic actuated gun cartridges, quarts, gallons, pails and drums. Custom packaging, such as premixed and degassed frozen cartriges, is also available.