Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Impact Properties

- Injection Molding

- Flame Characteristics

- Note

- ᵈ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding. Do NOT mix NORYL GTX* resin with other grades of NORYL* resins. Polystyrene and acrylic regrind are effective purging Materials. Use temperature range appropriate for particular purging resin. Regrind must also be dried. Maximum 25% regrind. Dry at recommended temperatures and times for optimum performance. Overdrying can cause loss of physical properties and/or create appearance defects. Do not exceed recommended basic drying time and temperature above or:\n4-8 hrs at 95°C (200°F), 10 hrs max\n6-12 hrs at 80°C (175°F), 16 hrs max\n8-16 hrs at 65°C (150°F), 24 hrs max\nAVOID air circulating tray ovens. Moisture levels in heated ambient air can exceed moisture level in the resin itself, causing moisture ABSORPTION not drying. Avoid melt temperature in excess of 300°C (575°F) and residence times over 6-8 minutes (may affect properties and/or appearance). Nozzle temperature controls assist in elimination of drool premature freeze-off. Shot sizes in excess of 50% barrel capacity can lead to difficulties in providing a consistent, homogenous plastic melt.

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Break, Type I, 5 mm/min) ¹¹ | 129 | MPa | ASTM D638 |

| Tensile Strain (Break, Type I, 5 mm/min) ¹¹ | 2.7 | % | ASTM D638 |

| Tensile Modulus (at 5 mm/min) ¹¹ | 10410 | MPa | ASTM D638 |

| Flexural Stress ¹¹ | 199 | MPa | ASTM D790 |

| Flexural Modulus ¹¹ | 9170 | MPa | ASTM D790 |

| Tensile Stress (Break, 5 mm/min) ¹¹ | 130 | MPa | ISO 527 |

| Tensile Strain (Break, 5 mm/min) ¹¹ | 2.6 | % | ISO 527 |

| Tensile Modulus (at 1 mm/min) ¹¹ | 10640 | MPa | ISO 527 |

| Flexural Stress (Yield, at 2 mm/min) ¹¹ | 203 | MPa | ISO 178 |

| Flexural Modulus (at 2 mm/min) ¹¹ | 9290 | MPa | ISO 178 |

| Value | Units | Test Method / Conditions | |

| Specific Gravity ¹¹ | 1.26 | — | ASTM D792 |

| Mold Shrinkage (flow, 3.2 mm) ᵍ ¹¹ | 0.1 - 0.3 | % | SABIC method |

| Mold Shrinkage (xflow, 3.2 mm) ᵍ ¹¹ | 0.2 - 0.5 | % | SABIC method |

| Melt Volume Rate (at 300°C, 5.0 kg) ¹¹ | 30 | cm³/10 min | ISO 1133 |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ | 123 | °C | ASTM D648 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, flow) ¹¹ | 0.000014 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) ¹¹ | 0.000081 | 1/°C | ASTM E831 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity ᵈ ¹¹ | 50000 - 5000000 | Ω.cm | ASTM D257 |

| Surface Resistivity ᵈ ¹¹ | 5000 - 500000 | Ω | ASTM D257 |

| Value | Units | Test Method / Conditions | |

| Charpy Impact (Unnotched, at 23°C) ¹¹ | 45 | kJ/m² | ISO 179/2C |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 591 | J/m | ASTM D4812 |

| Izod Impact (Notched, at 23°C) ¹¹ | 88 | J/m | ASTM D256 |

| Charpy Impact (Notched, at 23°C) ¹¹ | 9 | kJ/m² | ISO 179/2C |

| Value | Units | Test Method / Conditions | |

| Drying Temperature ⁷ | 90 - 110 | °C | — |

| Drying Time ⁷ | 3 - 5 | Hrs | — |

| Melt Temperature ⁷ | 280 - 320 | °C | — |

| Nozzle Temperature ⁷ | 280 - 320 | °C | — |

| Front - Zone 3 Temperature ⁷ | 280 - 320 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 280 - 320 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 250 - 280 | °C | — |

| Mold Temperature ⁷ | 90 - 120 | °C | — |

| Back Pressure ⁷ | 1 - 5 | MPa | — |

| Screw Speed ⁷ | 30 - 100 | rpm | — |

| Value | Units | Test Method / Conditions | |

| UL Recognized (94HB Flame Class Rating) ᵖ | 1 | mm | UL 94 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

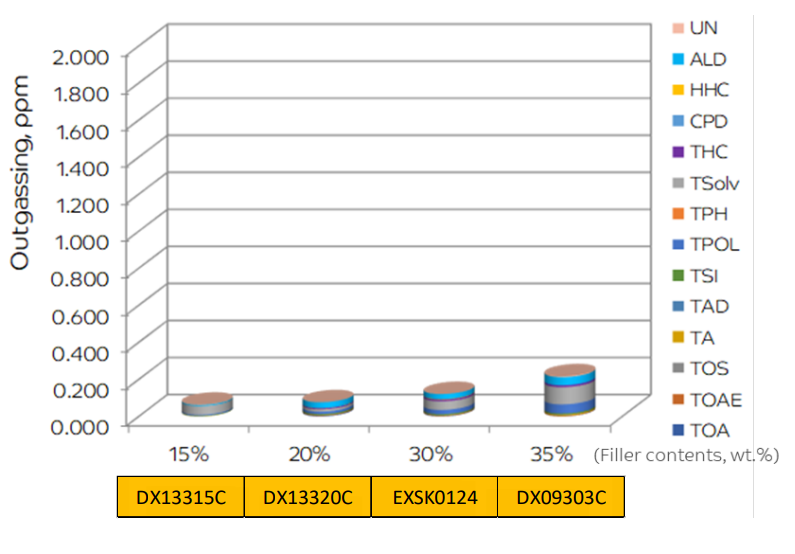

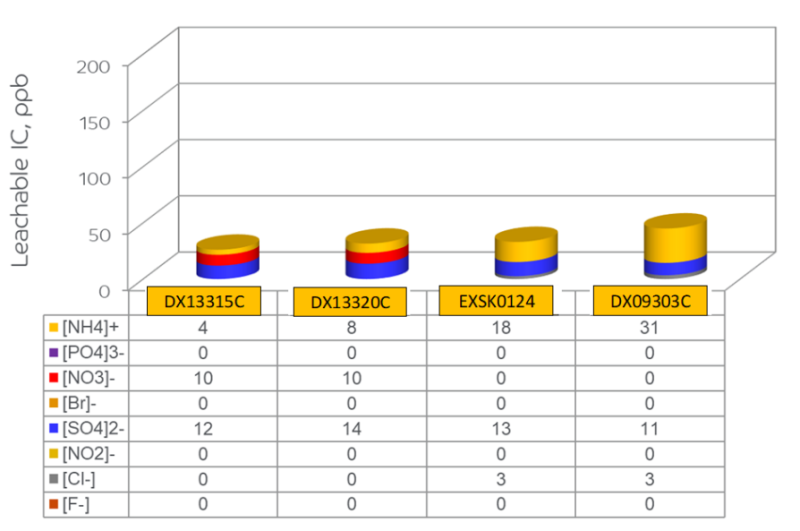

- Cleanliness Performance - Out Gassing, Leachable Ions

Fig 1: Total Outgassing

Fig 2: Leachable ions

Packaging & Availability

- Country Availability

- Regional Availability