Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Characteristics

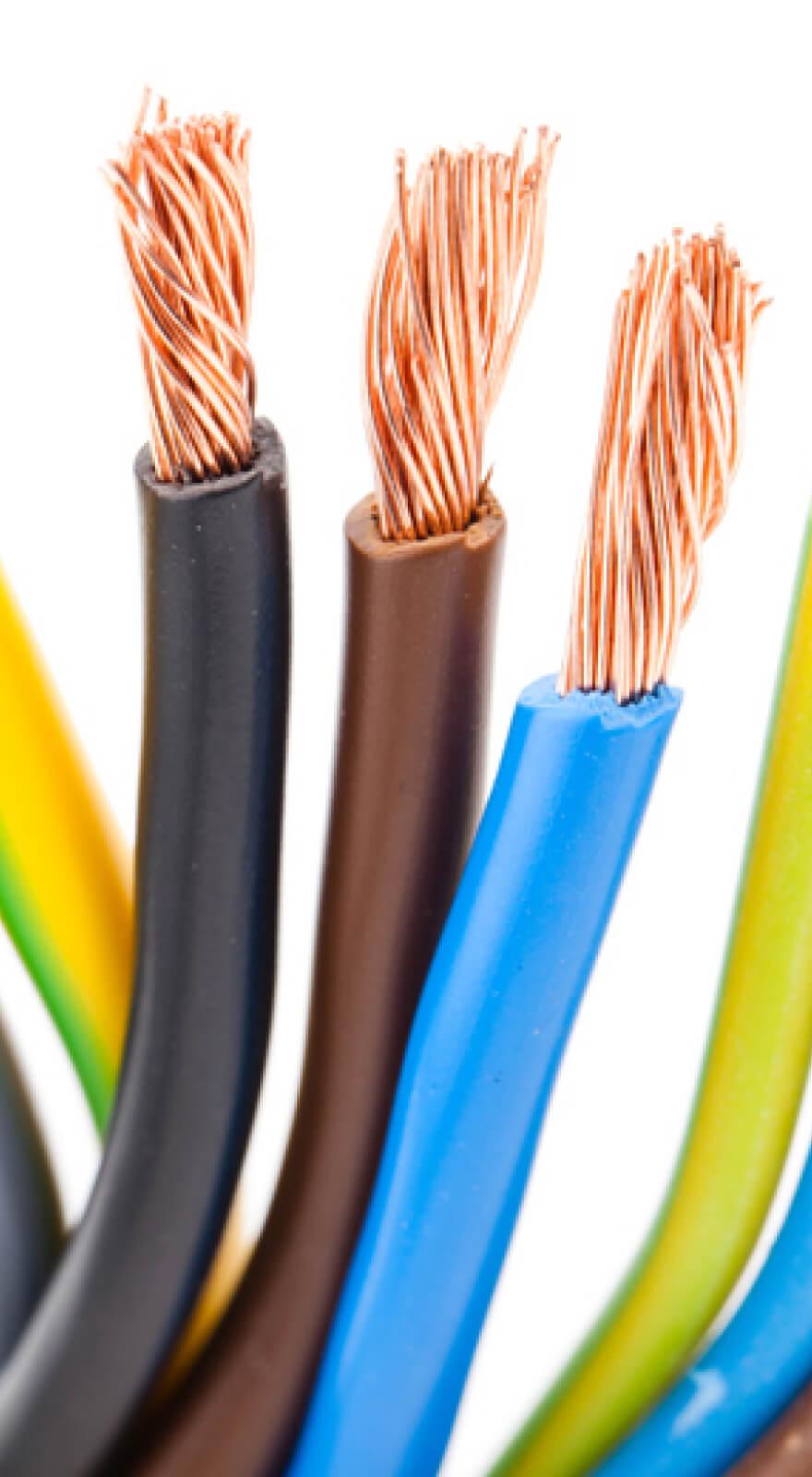

Low density, moisture curable polyethylene, for low voltage building wire, control cable, photovoltaic and cable tray applications (UL styles SIS, XHHW, XHHW-2, RHW, RHW-2, PV VW-1; ‘SUNRES’ and -40°C).

Applications & Uses

- Markets

- Applications

- Cure Method

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Physical Properties

- Mechanical Properties

- Fire & Smoke Properties

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (at 190°C / 2.16kg) | 1 | g/10min | ASTM D1238 |

| Value | Units | Test Method / Conditions | |

| Dielectric Breakdown (After Glancing Impact0 | 21 | kV | UL 2556 |

| Elongation Under Load (Hot Elongation Test: 15 min / 150°C, 0.2 N/mm² Load) | 45 | % | SACO AEI DWI-QA-4007 based on ICEA T-28-562 |

| Crushing Test | 1360 | lbs | UL 1581 / UL 2556 |

| Deformation | 9 | % | — |

| Degree of Cross-linking | 60 | % | ASTM D2765 |

| Dielectric Constant (1MHz - 100MHz Range) | 2.56 | — | ASTM D150 |

| Elongation at Break | 300 | % | UL 2556 |

| Elongation at Break (After Gasoline: 30 Days at 23°C) | 320 | % | UL 2556 |

| Elongation at Break (After Oil: 60 Days at 75°C) | 290 | % | UL 2556 |

| Elongation at Break (After Thermal Aging: 7 Days at 121°C) | 300 | % | UL 2556 |

| Dielectric Breakdown (Initial) | 30 | kV | UL1581 |

| Low Temperature Brittleness Point (LTBP) | max. -60 | °C | ASTM D746 |

| Relative Permittivity (SIC) (at 90°C) | 3.1 | % | UL 1581 / UL 2556 |

| Specific Gravity (at 23°C) | 1.3 | g/cm³ | ASTM D792 |

| Tensile Strength at Break | 1930 | psi | UL1581 |

| Tensile Strength at Break (After Gasoline: 30 Days at 23°C) | 1790 | psi | UL1581 |

| Tensile Strength at Break (After Oil: 60 Days at 75°C) | 1815 | psi | UL1581 |

| Tensile Strength at Break (After Thermal Aging: 7 Days at 121°C) | 1950 | psi | UL1581 |

| Value | Units | Test Method / Conditions | |

| FV-2 / VW-1 Flame Test | Pass | % | UL 1581 / UL 2556 |

| Limiting Oxygen Index | 27 | % | ASTM D2863 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Processing

The pre-grafted base PEXIDAN® A-3001 must be added with type CAT-083FR-UV flame retardant catalyst masterbatch in the proportion 50:50 by weight. We strongly suggest dosing the two components directly in the throat of the extruder using a gravimetric or loss-in-weight feeder. In order to prevent scorching the grafted compound and the catalyst masterbatch must be stored separately and mixed just prior to consumption.

PEXIDAN® V/T-2UV can be processed with PE single screw extruders having proper temperature control and a good mixing screw (2.5:1 ratio at least).

The following temperature profile is suggested:Barrel Zones Head Die Celsius 154°-171°C 185°C 185°C Fahrenheit 310°-340°F 365°F 365°F These conditions may depend on the equipment being used. It is recommended using conveyors and tools shaped in order to prevent stagnation in the head. In case of prolonged shutdown, purge the extruder with LDPE.

- Curing

Curing can be done by immersion in hot water at 70°-95°C, or by exposure to low pressure steam. In all cases curing time depends on wall thickness, temperature, relative humidity and quantity of wire on the reel.

- Color Masterbatches

A wide range of commonly used color masterbatches based on LDPE are available. A use level of 1.5% by weight should give an acceptable color but this will be dependent upon the concentrate itself. Levels of concentrates should be kept to a minimum because they can detract from performance. It is recommended that the catalyst and color masterbatches be dried prior to usage 4-6 hours at 60°C (150°F) using a desiccant dryer. When using color masterbatch in an outdoor (SUNRES) application, it is important to select a masterbatch that will remain color-fast and not fade when outdoor weathered, that is a masterbatch in which the pigment is UV stable. SACO recommends consulting your color masterbatch supplier for guidance.

Packaging & Availability

- Packaging Type

- Packaging

The physical form of both PEXIDAN® A-3001 and CAT-083FR is free flowing pellets, available in 1500 lb (680 kg) and 2000 lb (907 kg) gaylords respectively, or in 300 lb (136 kg) fiber drums.

Storage & Handling

- Storage & Shelf Life

Due to the moisture sensitivity of PEXIDAN®, SACO AEI Polymers suggests that the following points should be considered when storing the materials:

Other precautions are:- Packaging should remain sealed

- Avoid temperature above 30C

- Avoid storage outside and in direct sunlight

- Use within 8 hours of opening packaging