Knowde Enhanced TDS

Identification & Functionality

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Features and Major Physical Properties of Product

- *1 - The board was cut using an NC machine. The surface roughness of the cut section was measured through the use of a non-contact three-dimensional surface roughness tester. The surface roughness is the average absolute value of irregularities; and the lower the value, the smoother the surface.

- *2 - The milling resistance during cutting through the use of an NC machine driven with 4-component dynamometer under the following conditions was measured: Edge: through-away tip of carbide tool with a diameter of 16 mm, Revolution rate: 5,000 rpm, Feed speed: 2,000 mm/min, Cut depth: 3 mm

- *3 - The board was cut continuously for 10 m using an NC machine under the following conditions: Edge: normal cutting edge of high-speed steel with a diameter of 10 mm, Revolution rate: 10,000 rpm, Feed speed: 100 mm/min, Pick: 1 mm, Cut depth: 3 mm The degree of abrasion of the cutter edge after cutting was visually evaluated with a stereomicroscope (magnification: 50).

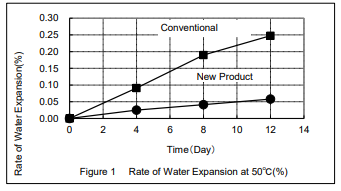

- *4 - A test piece of 50 (w) × 50 (d) × 120 (h) mm measured height after kept for 12 hours at 25 ℃ in air, and soaked for a few days in water at 50 ℃.Then kept for 12 hours in water at 25 ℃, and mesured height. Rate of water expansion was calculated using its two heights.

Rate of Water Expansion at 50℃(%)

- Features

- Lower rates of moisture expansion, This is less than one-quarter that of a conventional product.

- Improving deflection temperature to 95°C

- Maintaining other performance of conventional product

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Abrasion of Cutter Edge | 1 | mm | — |

| Hardness | 64 | Shore D | — |

| Coefficient of Linear Thermal Expansion | 47 | 10^-6/°C | TMA |

| Deflection Temperature Under Load | 95 | °C | — |

| Density (at 25°C) | 750 | Kg/m3 | ASTM D792 |

| Flexural Strength | 25 | MPa | JIS K 6911 |

| Impact Strength | 5.7 | kJ/m2 | — |

| Milling Resistance | 80 | N | — |

| Rate of Water Expansion (50℃) % | 0.06 | % | — |

| Surface Roughness(Ra) | 4 | μm | — |