Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features and Benefits

Crestamold® matched tooling systems offer a fast and effective way to produce molds for the manufacture of rail components. Our low-profile laminating and infusion resins minimize shrinkage to improve the dimensional accuracy of molds combined with gelcoat and skincoat products to deliver a high quality and robust mold surface.

Mold Manufacture

Crestamold® Resin

Crestamold® Rapid Tooling Resin (RTR) 4010PA is a rapid tooling resin which incorporates outstanding handling properties, lower viscosity, improved shrinkage control and is catalyzed with standard MEKP catalyst. It enables faster mold making and eliminates surface distortion.

Crestamold® Skin Coat

Crestamold® Skin Coats VE679PA and VE690PA are pre-accelerated thixotropic DCPD modified vinylester resins that have been developed as a skin coat in tooling applications. They have excellent blister resistance and reduced print through.

Crestamold® Gelcoat

Crestamold® Gelcoat 15PA is a superior performance vinylester tooling gelcoat for making molds designed to have a long service lifetime and retain high gloss levels after multiple pulls. It is easy to apply and achieves good coverage. There is no gassing of the gelcoat ensuring a very low porosity surface and it cures with a standard MEKP catalyst. Available in both spray and brush.

Plug Manufacture

Crystic® Primecoat

Crystic® Primecoat is a high build, polyester coating material which allows the rapid surfacing of patterns constructed from materials such as wood, MDF and GRP. It can be applied wet-on-wet up to a thickness of 1.5mm in one operation without sagging or draining from vertical surfaces.

Crestafix® Fairing Compound

A water resistant, low-density polyester-based fairing compound, Crestafix® F26 has excellent adhesion to cured fiber-reinforced polyester and vinylester laminates. The material sands easily, gives a hard finish after a full cure, yet is not brittle and has good impact strength. Crestafix® F26 is a suitable base for all marine finishes such as polyester, urethane and epoxy paints.

Crestamould® Sealer

Laminating with polyester resin on top of polystirene foams has never been possible despite various impractical methods of protection from preventing the stirene foam from dissolving when in contact with polyester resin. Crestamould® B21 sealing resin solves this problem – just one coat applied by brush will seal the surface and laminating with polyester resins can begin two hours after application.

Crystic® Glosscoat

Crystic® Glosscoat is a polyester coating designed to be applied over prepared Crestamould® Primecoat to give a glossier and more durable surface. The material hardens rapidly and can be easily sanded to a smooth surface which can be polished to high gloss.

Crestamould® Tooling Paste

Designed for milling of large plugs or direct limited production molds with CNC multiple axis machines, Crestamould® T29 is a modified polyester compound, available in sprayable or extrudable versions.

Applications & Uses

- Applications

- Applications

Crestamould® VE 679PA was developed for use as a skin coat in marine and tooling applications when used with a minimum of one layer of 300gm/450gm CSM glass.

- Formulation

Crestamould® VE 679PA must be thoroughly stirred and allowed to attain workshop temperature (18° - 20°C ) before use. It needs only the addition of a catalyst to start the curing reaction. Either Butanox LPT or Butanox M50 catalyst can be used, which should be added at 2% into the resin. The geltime of Crestamould® VE 679PA can be approximately determined from the table below.

- Pot Life

Temperature Pot Life in Minutes Using 2% Butanox LPT Pot Life in Minutes Using 2% Butanox M50

15°C 50 minutes 50 minutes 20°C 28 minutes 34 minutes 25°C 18 minutes 23 minutes

Properties

- Color

- Typical Liquid Resin Properties

- Resin Properties - Unfilled Casting (Cured)

- Note

* Curing Schedule - 24hrs @ 20°C, 16hrs @ 40°C.

† Curing Schedule - 24hrs @ 20°C, 5 hrs @ 80°C, 3 hrs @ 120°C.

** Curing Schedule - 24hrs @ 20°C, 3hrs @ 80°C .

| Value | Units | Test Method / Conditions | |

| Viscosity (at 25°C, 37.35 s⁻¹) | 3.5 | Poise | BS or BS EN ISO test method |

| Viscosity (at 25°C, 4500 s⁻¹) | 2.3 | Poise | BS or BS EN ISO test method |

| Specific Gravity (at 25°C) | 1.065 | g/cm³ | BS or BS EN ISO test method |

| Stability (in dark at 25°C) | 6 | Months | BS or BS EN ISO test method |

| Gel Time (at 25°C, using 2% Butanox LPT) | 18 | Minutes | BS or BS EN ISO test method |

| Gel Time (at 25°C, using 2% Butanox M50) | 23 | Minutes | BS or BS EN ISO test method |

| Value | Units | Test Method / Conditions | |

| Barcol Hardness (GYZJ 934 - 1)* | 23 | — | BS or BS EN ISO test method |

| Deflection Temperature (under load 1.80 MPa)* | 60 | ºC | BS or BS EN ISO test method |

| Water Absorption (24h, at 23°C)* | 10 | mg | BS or BS EN ISO test method |

| Tensile Strength* | 60 | MPa | BS or BS EN ISO test method |

| Tensile Modulus* | 2.7 | GPa | BS or BS EN ISO test method |

| Elongation (at break)* | 4.3 | % | BS or BS EN ISO test method |

| Specific Gravity (at 25°C)* | 1.161 | g/cm³ | BS or BS EN ISO test method |

| Barcol Hardness (GYZJ 934 - 1)** | 35 | — | BS or BS EN ISO test method |

| Deflection Temperature under load (1.80 MPa)† | 94 | ºC | BS or BS EN ISO test method |

| Water Absorption (24h, at 23°C)** | 15 | mg | BS or BS EN ISO test method |

| Tensile Strength** | 52 | MPa | BS or BS EN ISO test method |

| Tensile Modulus** | 3 | GPa | BS or BS EN ISO test method |

| Elongation (at break)** | 2.1 | % | BS or BS EN ISO test method |

| Specific Gravity (at 25°C)** | 1.158 | g/cm³ | BS or BS EN ISO test method |

Regulatory & Compliance

- Approvals

Crestamould® VE 679PA is approved by Lloyd’s Register of Shipping for use in the construction of craft under their survey.

Technical Details & Test Data

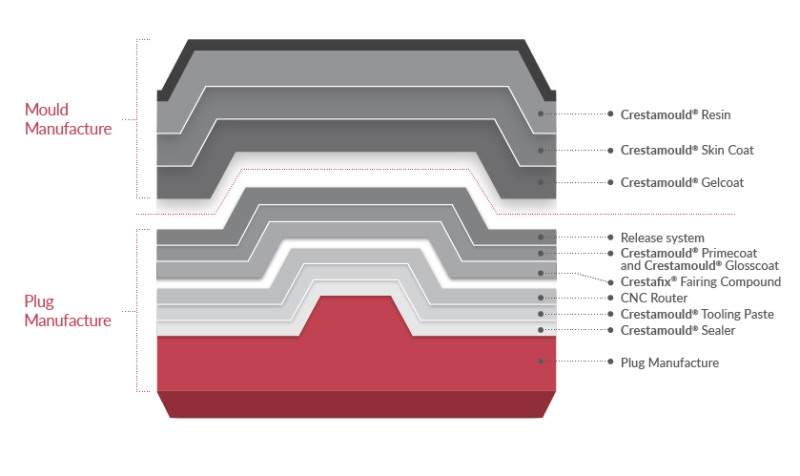

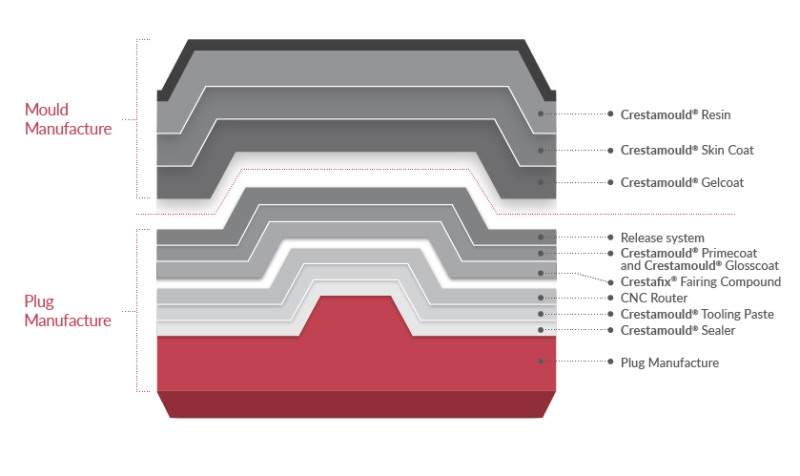

- Crestamould® Matched Tooling Systems

Crestamould® matched tooling systems offer a fast and effective way to produce moulds for the manufacture of rail components. Our low-profile laminating and infusion resins minimise shrinkage to improve the dimensional accuracy of moulds combined with gelcoat and skincoat products to deliver a high quality and robust mould surface.

Mould Manufacture

Crestamould® Resin

Crestamould® Rapid Tooling Resin (RTR) 4010PA is a rapid tooling resin which incorporates outstanding handling properties, lower viscosity, improved shrinkage control and is catalysed with standard MEKP catalyst. It enables faster mould making and eliminates surface distortion.

Crestamould® Skin Coat

Crestamould® Skin Coats VE679PA and VE690PA are pre-accelerated thixotropic DCPD modified vinylester resins that have been developed as a skin coat in tooling applications. They have excellent blister resistance and reduced print through.

Crestamould® Gelcoat

Crestamould® Gelcoat 15PA is a superior performance vinylester tooling gelcoat for making moulds designed to have a long service lifetime and retain high gloss levels after multiple pulls. It is easy to apply and achieves good coverage. There is no gassing of the gelcoat ensuring a very low porosity surface and it cures with a standard MEKP catalyst. Available in both spray and brush.

Plug Manufacture

Crystic® Primecoat

Crystic® Primecoat is a high build, polyester coating material which allows the rapid surfacing of patterns constructed from materials such as wood, MDF and GRP. It can be applied wet-on-wet up to a thickness of 1.5mm in one operation without sagging or draining from vertical surfaces.

Crestafix® Fairing Compound

A water resistant, low-density polyester-based fairing compound, Crestafix® F26 has excellent adhesion to cured fibre-reinforced polyester and vinylester laminates. The material sands easily, gives a hard finish after a full cure, yet is not brittle and has good impact strength. Crestafix® F26 is a suitable base for all marine finishes such as polyester, urethane and epoxy paints.

Crestamould® Sealer

Laminating with polyester resin on top of polystyrene foams has never been possible despite various impractical methods of protection from preventing the styrene foam from dissolving when in contact with polyester resin. Crestamould® B21 sealing resin solves this problem – just one coat applied by brush will seal the surface and laminating with polyester resins can begin two hours after application.

Crystic® Glosscoat

Crystic® Glosscoat is a polyester coating designed to be applied over prepared Crestamould® Primecoat to give a glossier and more durable surface. The material hardens rapidly and can be easily sanded to a smooth surface which can be polished to high gloss.

Crestamould® Tooling Paste

Designed for milling of large plugs or direct limited production moulds with CNC multiple axis machines, Crestamould® T29 is a modified polyester compound, available in sprayable or extrudable versions.

- Additives

The addition of pigment, fillers or other additives may adversely affect the resin properties. Users should consult Scott Bader’s Technical Service Department before making any such additions.

Packaging & Availability

- Packaging Information

Crestamould® VE 679PA is supplied in 25kg and 200kg steel containers.

Storage & Handling

- Storage Conditions

Crestamould® VE 679PA should be stored in the dark in suitable closed containers. It is recommended that the storage temperature should be less than 20°C where practical, but should not exceed 30°C. Ideally, containers should be opened only immediately prior to use.