Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Product Highlights

Crystic199 is an isophthalic polyester resin. It is recommended for use in high performance applications, such as the aircraft industry, where superior thermal and electrical properties are required. Fully cured laminates made with Crystic 199 have excellent chemical and heat resistance. They can withstand long periods (1 year) at temperatures up to 150ºC, and shorter periods at temperatures up to 200ºC, with no serious loss of properties.

Applications & Uses

- Markets

- Composites End Use

- Formulation Guidelines

Crystic199 can be used in both hot and cold curing formulations.

Hot Curing

The recommended catalyst is Perkadox CH50X (or equivalent) which should be added at 2 % into the resin. The catalyst must be thoroughly dispersed into the resin, and the catalyzed mix will remain usable for approximately 6 days at workshop temperature (18ºC - 20ºC). Cure will take place at temperatures between 80 ºC and 130 ºC, but for most applications 120 ºC will be satisfactory. For optimum heat resistant properties, the laminate should be cured at a temperature of 80 ºC – 100 ºC for half an hour to one hour, and then post cured.

Cold Curing- Crystic® 199 should be allowed to attain workshop temperature (18ºC-25ºC) before use. It requires the addition of a catalyst and an accelerator to start the curing reaction.

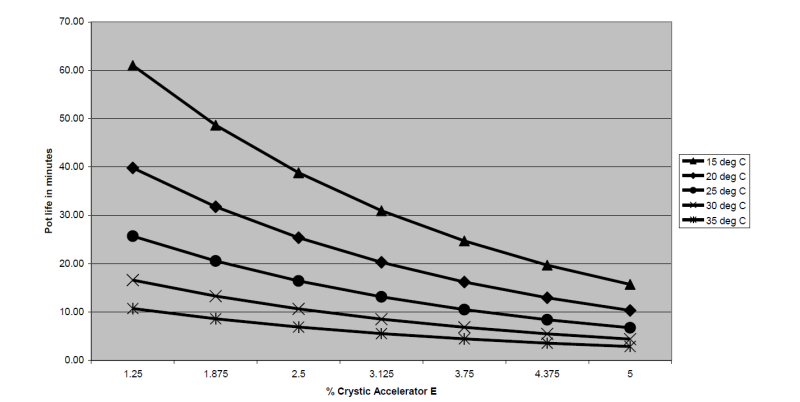

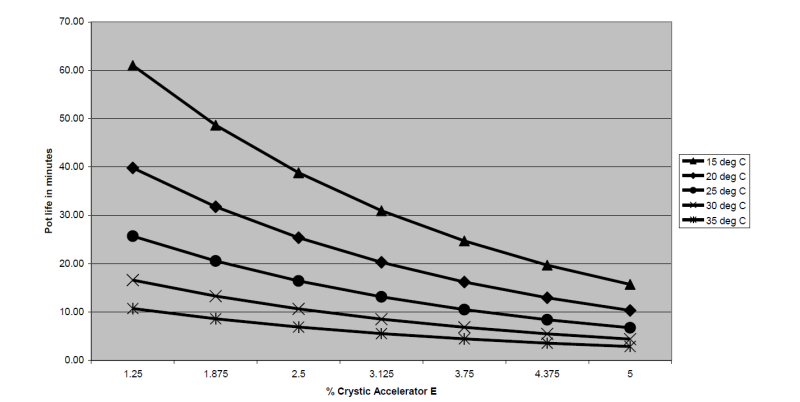

- The recommended catalyst is Andonox® KP9. The catalyst should be added at 2% into the resin, and thoroughly dispersed. This mix will remain usable for approximately 8 hours at workshop temperature (18ºC - 25ºC). Shortly before use, the correct amount of Crystic® Accelerator E should be stirred into the catalysed resin. The amount of Crystic® Accelerator E can be approximately determined from the chart below:

Crystic 199 - Geltimes at varying temperatures with 2% Andonox KP9

- Pot Life

Crystic199 can be used in both hot and cold curing formulations.

Hot Curing

The recommended catalyst is Perkadox CH50X (or equivalent) which should be added at 2 % into the resin. The catalyst must be thoroughly dispersed into the resin, and the catalyzed mix will remain usable for approximately 6 days at workshop temperature (18ºC - 20ºC). Cure will take place at temperatures between 80 ºC and 130 ºC, but for most applications 120 ºC will be satisfactory. For optimum heat resistant properties, the laminate should be cured at a temperature of 80 ºC – 100 ºC for half an hour to one hour, and then post cured.

Cold Curing- Crystic® 199 should be allowed to attain workshop temperature (18ºC-25ºC) before use. It requires the addition of a catalyst and an accelerator to start the curing reaction.

- The recommended catalyst is Andonox® KP9. The catalyst should be added at 2% into the resin, and thoroughly dispersed. This mix will remain usable for approximately 8 hours at workshop temperature (18ºC - 25ºC). Shortly before use, the correct amount of Crystic® Accelerator E should be stirred into the catalyzed resin. The amount of Crystic® Accelerator E can be approximately determined from the chart below:

Crystic 199 - Geltimes at varying temperatures with 2% Andonox KP9

Properties

- Color

- Typical Properties

- Typical Cast Unfilled Resin Properties

- Note

*Curing schedule - 24hrs @ 20ºC, 3hrs @ 80ºC

†Curing schedule - 24hrs @ 20ºC, 5hrs @ 80ºC, 3hrs @120ºC

| Value | Units | Test Method / Conditions | |

| Acid Value | 27 | mg KOH/g | BS 2782 |

| Viscosity (at 25°C, 37.35 s⁻¹) | 700 | Centipoise | BS 2782 |

| Specific Gravity (at 25°C) | 1.1 | — | BS 2782 |

| Stability (with storage recommendations) | 9 | Months | BS 2782 |

| Volatile Content | 37 | % | BS 2782 |

| Value | Units | Test Method / Conditions | |

| Gel Time (at 25°C, using 2% Andonox® KP9, 2% Crystic® Accelerator E) | 20 | Minutes | BS 2782 |

| Barcol Hardness (Model GYZ 934-1) | 48 | — | BS 2782 |

| Water Absorption (24h, at 23°C) | 29 | mg | BS 2782 |

| Deflection Temperature (under load 1.80 MPa) †* | 119 | ºC | BS 2782 |

| Elongation (at break) | 1.7 | % | BS 2782 |

| Tensile Strength | 55 | MPa | BS 2782 |

| Tensile Modulus | 3300 | MPa | BS 2782 |

| Specific Gravity (at 25°C) | 1.19 | — | BS 2782 |

| Refractive Index (n 20/d) | 1.554 | — | BS 2782 |

| Dielectric Loss (tan δ at 1000Hz) | 0.005 | — | BS 2782 |

| Dielectric Constant (at 1000Hz) | 3.1 | — | BS 2782 |

Regulatory & Compliance

- Approvals

Crystic 199 meets the requirements of BS 3532 : 1990 Type C, and is approved to DTD 5537 and 5549, Class MC and EC.

Technical Details & Test Data

- Additives

The post curing temperature will depend on the temperature which the laminate is to withstand. It should be increased in increments of 20ºC to the final operating temperature, with a minimum of five hours post curing time at each 20ºC increase.

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging

Crystic® 199 is supplied in 25kg kegs, 225kg drums, and 1125kg intermediate bulk containers. Bulk supplies can be delivered by road tanker.

Storage & Handling

- Storage

Crystic® 199 should be stored between 5°C and 25°C in the original, unopened container in a dry, well ventilated place. Protect from freezing and direct sunlight. Avoid contact with oxidising agents. If stored outside of these recommendations, shelf life will be significantly reduced