Knowde Enhanced TDS

Identification & Functionality

- Base Oil Type

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- ZEROL® PAG Advantages

- Excellent miscibility in HFC R-134a.

- Superior lubricity compared to alternative synthetic technologies (e.g. polyol esters) and mineral oils.

- Exceptional Viscosity Index (VI) – The high VI of ZEROL PAG series lubricants enhances compressor life by ensuring efficient running over a wide operating temperature range. The high Viscosity Index may also allow the user to select a lower viscosity fluid than typically used, with associated power savings.

- Excellent chemical, thermal and hydrolytic stability, resulting in reduced downtime and lower maintenance costs.

- Formulating expertise – Shrieve ZEROL PAG lubricants contain optimized additive technology to provide additional corrosion protection within the a/c system, to further enhance the extreme pressure and antiwear performance of the PAG, and to maximize fluid life by ensuring against thermal or oxidative deterioration of the lubricant.

Applications & Uses

- Applications

- Application Area

Properties

- ISO Viscosity Grade

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (at 40°C) | 47.0 | cSt | — |

| Viscosity (at 100°C) | 10.0 | cSt | — |

| Viscosity Index | 178.0 | — | — |

| TAN | max. 0.10 | mgKOH/g | — |

| Flash Point (COC) | 238.0 | °C | ASTM D92 |

| Specific Gravity (at 20°C) | 1.034 | g/cc | — |

| Pour Point | -50.0 | °C | ASTM D97 |

| Moisture Content | max. 500 | ppm | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Sealed Glass Tube Data

The chemical, thermal and hydrolytic stability of ZEROL PAG lubricants has been evaluated using ASHRAE 97 sealed glass tube testing.

Testing was conducted under standard conditions of 50/50 wt/wt R134a/lubricant with 1000ppm water at 175°C, for 14 days. The metal coupons (Fe/Al/Cu) remained clean, bright and free from corrosive or oxidative deposits with post-lubricant analysis confirming an absence of color degradation and low post-test TAN values.

Miscibility in R-134a

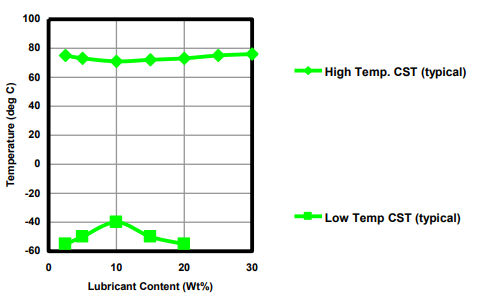

Miscibility of the lubricants in R-134a refrigerant has been evaluated in accordance with ASHRAE 86 miscibility procedure, to determine the Critical Solution Temperature (CST) as it varies with lubricant concentration in the refrigerant. The chart below shows a typical CST curve (using ZEROL PAG 46)

The ISO 46 ZEROL PAG oil shows a region of low temperature and high temperature immiscibility (below and above the respective curves), which is typical of PAGs. As the typical operating temperatures for mobile a/c systems are within the region of miscibility, the broad miscibility range ensures efficient and reliable compressor operation in R-134a systems without any adverse effects on oil return or compressor lubrication, as may typically be observed with less miscible lubricants.

Conclusion

Shrieve ZEROL PAG series are a high quality range of mobile a/c compressor lubricants, demonstrating performance levels superior to many existing commercial standards. Together with the premium range of ZEROL RFL lubricants, Shrieve PAG based lubricants offer outstanding performance to ensure maximum efficiency and reliability of mobile a/c systems.

- Technical Performance

Extreme Pressure (EP) Performance

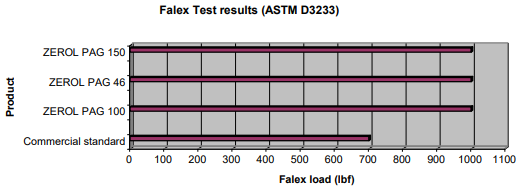

The chart on page 2 illustrates the results of extreme pressure lubricity tests conducted on the ZEROL PAG series lubricants using the FALEX test method ASTM D3233. Performance is compared to a standard commercially available PAG lubricant of the same ISO viscosity grade.

The results confirm the superior extreme pressure performance of ZEROL PAG lubricants. This test method provides a useful indicator of the ability of the oil to reduce compressor wear, reduce friction, improve system efficiency and lower maintenance costs.Technical Performance

Extreme Pressure Performance - Falex Test Results