Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Agrochemical Functions

- Technologies

- Product Families

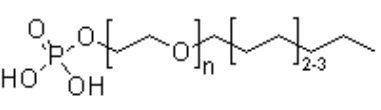

- Chemical Structure

Features & Benefits

- Labeling Claims

- Agrochemicals Features

Properties

- Physical Form

- Appearance

- Clear viscous liquid (at 25°C)

- Soluble in

- Water

- Insoluble in

- Mineral oil

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH (5% in water, at 20°C) | max. 2.0 | - | - |

| Viscosity (at 60°C) | 200.0 | mPa.s | - |

| Density (at 25°C) | 1.2 | g/cm³ | - |

| Active Content | min. 97.5 | % | - |

| Flash Point | min. 93 | °C | - |

| Color | max. 8 | Gardner | - |

Regulatory & Compliance

Safety & Health

- Safety Precautions

Normal safety precautions (e.g., gloves and safety goggles) should be employed when handling STEPFAC™ 810. Contact with eyes, nose or prolonged contact with skin should be avoided. Wash thoroughly after handling STEPFAC™ 810

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace safety practices should be used to control these exposures.

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage and Handling Conditions

Non-Bulk Storage Recommendations: STEPFAC™ 810 should be stored in closed containers and kept in a cool, dry place between 15°C and 40°C (59°F and 104°F) away from incompatible materials (see Section 10 of the SDS). Avoid overheating or freezing. If material is frozen it should be heated gently and stirred to ensure it is homogeneous before use.