Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Food Ingredients Functions

- Ingredients

- Maltodextrin, Lactose, Transglutaminase

- Technologies

- Product Families

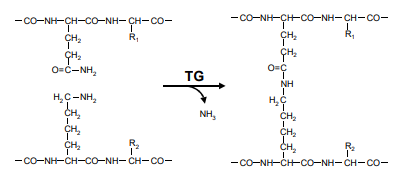

- Chemical Structure

- Origin

Non-pathogenic Streptoverticillium mobaraense (GRAS status)

Features & Benefits

- Food Ingredients Features

- Properties

- Increases yield

- Covalently links proteins

- Improves temperature resistance

- Improves Texture

Applications & Uses

- Markets

- Food & Nutrition Applications

- Applications

- Cheese

- Fresh Cheese

- Curd Cheese

- Yogurt

- Dosage

The typical dosage is 1-10 Unit per 1 g of milk protein to improve the texture of fresh cheese and yogurt. The addition of caseinate can improve the effect of the transglutaminase.

The optimal dosage depends greatly on process conditions and the quality of the raw material and may therefore deviate from the suggested dosage. Finding the optimal dosage for each individual process should be evaluated at actual production sites.

Properties

- Appearance

- Granulated powder

- Chemical Properties

- Typical Properties

- Microbiological Values

| Value | Units | Test Method / Conditions | |

| Arsenic Content | max. 3 | mg/kg | AAS |

| Cadmium Content | max. 0.5 | mg/kg | AAS |

| Lead Content | max. 10 | mg/kg | AAS |

| Loss on Drying | max. 14 | g/100g | drying oven; 3h 105°C |

| Mercury Content | max. 0.5 | mg/kg | AAS |

| Value | Units | Test Method / Conditions | |

| Transglutaminase | 450 - 500 | u/g | Hydroxamate Assay |

| Value | Units | Test Method / Conditions | |

| Escherichia coli | Negative | cfu/25g | M. Colif.-Agar 36°C/48h |

| Salmonella | Negative | cfu/25g | DIN EN ISO 6579 |

| Total Plate Count | max. 50000 | cfu/g | DIN EN ISO 4833 |

Regulatory & Compliance

- Certifications & Compliance

- Regulatory Information

Allergen Information: contains the allergen milk and lactose according to Regulation (EU) No 1169/2011, Annex II

Health Information: The products are suitable for human consumption if used accordingly to recommendations and officially allowed to be sold within Germany and the EU. The product is food grade and conforms with the current European food law.

GMO: This product is not a genetically modified organism (GMO), nor does it contain any GMO or any recombinant DNA.

All the non-enzymatic constituents of the product (e.g. carriers, stabilizing agents, free-flowing agents etc.) originate from non-genetically modified sources. Due to the ubiquitous presence of GMO organisms, absence of minor traces of GMO material cannot be guaranteed, but in any case, the content of unintentionally present GMO material will be below 0.9%, in accordance to Regulation (EC) No 1830/2003 and Regulation (EC) No1829/2003. The product is used as processing aid in food manufacturing processes, and therefore labeling is not required in the EU. National regulations must be observed.

Product suitability:

Yes No Vegetarian X Vegan X BSE/TSE Information: The mentioned product does not represent a BSE (Bovine Spongiform Encephalopathy) and/or TSE (Transmissible Spongiform Encephalopathy) risk. Irradiation: Neither the product nor its ingredients have been treated with ionizing radiation according to Directive 1999/2/EC and 1999/3/EC.

Nanoparticles: The product does not contain ingredients in the form of engineered nanomaterials as defined in Regulation (EU) 2015/2283.

Contamination/Residues: The product complies with: Regulation (EC) No 396/2005 and its amendments regarding maximum levels for pesticide residues in foodstuffs. Regulation (EC) No 1881/2006 and its amendments regarding especially maximum levels for heavy metals, mycotoxins, dioxins and PCB in foodstuffs.

Conformity of the Packaging: The packaging material complies with the provisions of Regulation (EC) No 1935/2004 and Regulation (EU) No 10/2011.

Technical Details & Test Data

- Enzyme Activity and Stability Data

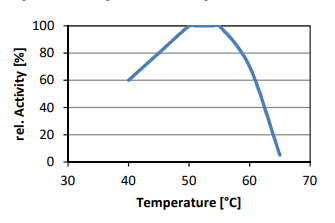

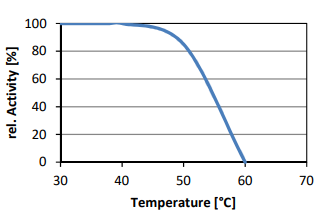

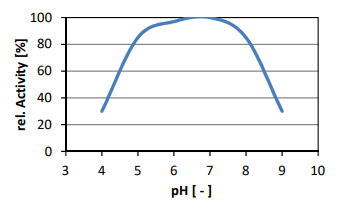

Transglutaminase 500 u/g (pH 7.0, 37 °C) pH optimum 6.0 – 7.0 pH optimum 50°C Fig. 1: Effect of the temperature on the activity of Dairyzym PT 500 LAC

(pH 6)

Fig. 2: Effect of the temperature on the Stability at pH 7 (10 min).

Fig. 3: Effect of the pH on the activity of Dairyzym PT 500 LAC (37 °C)

- Application Information

Cheese (e.g. Mozzarella, Feta, low fat cheese)

Application of transglutaminase can increase the yield of young cheese up to 15% by increase whey retention and improved moisture per protein yield. In low fat cheese taste and texture is improved due to the higher moisture.

Dose 5 Units transglutaminase per 1 g of milk protein together with the rennet and follow the cheese process as usual.

Curd Cheese (“Quark”)

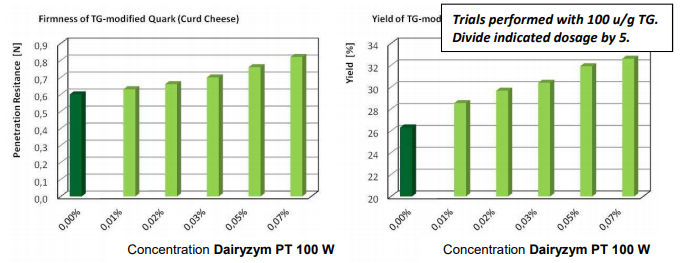

In curd cheese and fresh cheese applications, the transglutaminase addition can increase the yield by up to 25% (Fig. 5).

For applications before pasteurization:

Add 0.012-0.02% Dairyzym PT 500 LAC to milk and keep the milk for 2 hours at 25°C for the reaction of the transglutaminase.

For inactivation of the enzyme pasteurize the milk before the next step.

Add lactic acid bacteria and rennet and proceed as usual.

For applications after pasteurization:

Add 0.002-0.014% Dairyzym PT 500 LAC to milk. Furthermore, add lactic acid bacteria and rennet. Ferment for 6-18 hours at 27-38°C.

Process the following steps as usual.

Fig. 4: Improvement of Firmness and Yield of TG modified Quark

Yogurt (e.g. low fat)

In yogurt application, transglutaminase improves the textural properties of stirred and set type yogurts, especially low fat versions.

Stirred Yogurt

Pasteurize the milk prior application. Apply the transglutaminase together with the microorganism at 0.004-0.01% of final product weight (corresponds to approx. 1-3 Unit per 1 g of milk protein).

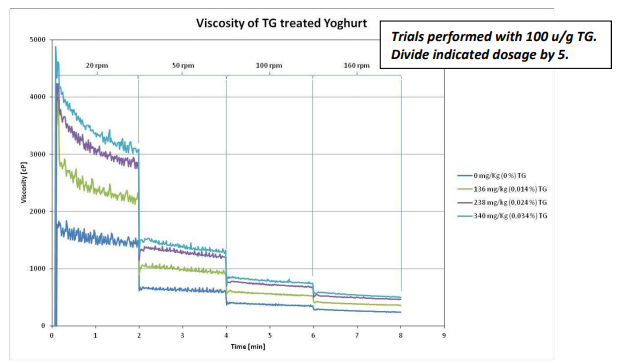

Dairyzym PT 500 LAC will increase the protein links during the fermentation, resulting in a higher viscosity (see Fig. 5).

Fig. 5: Viscosity of TG treated yogurt (38 °C, 12 h) aft er 24 h storage at 8°C.

Set Yogurt

Pasteurize the milk prior application. Apply transglutaminase together with the microorganism at 0.002-0.01% of final product weight (corresponds to approx. 1-3 Unit per 1 g of milk protein).

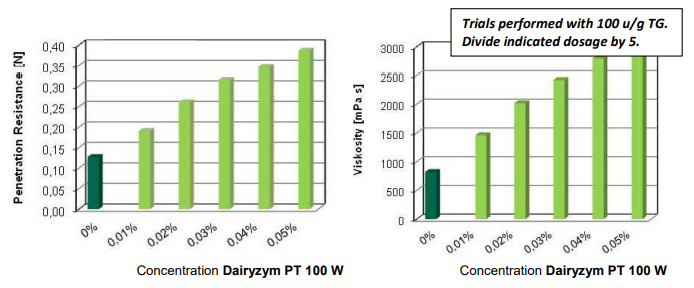

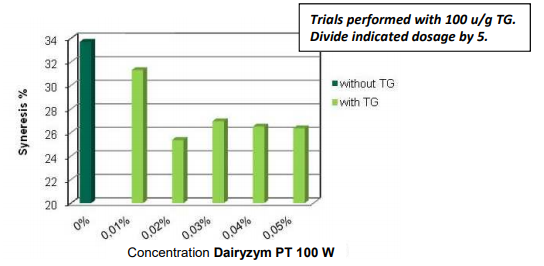

Dairyzym PT 500 LAC will increase the protein links during the fermentation; resulting in a firmer protein gel with higher viscosity and reduced syneresis (see Fig. 6).

Fig. 6: Improvement of Gel Penetration Resistance, Viscosity and Syneresis of set joghurt

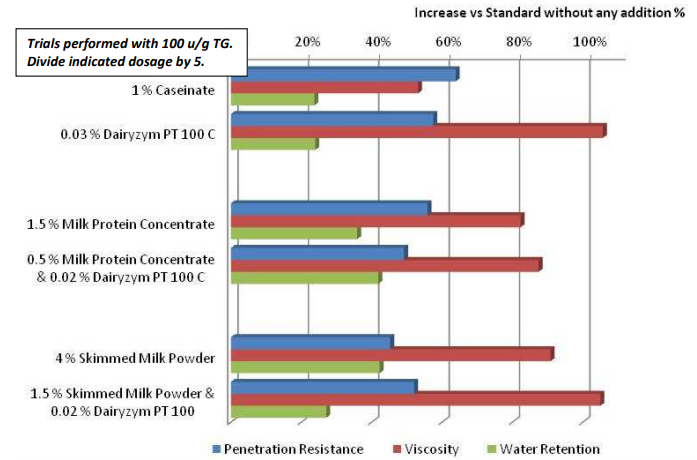

With the above-mentioned properties Dairyzym PT 500 LAC is able to replace milk proteins usually used to produce set type joghurt to achieve financial savings. However, also combinations with proteins, at a reduced dosage, will improve the texture together with economic benefits (Fig 7).

Fig. 7: Comparison of Transglutaminase against protein addition and combination of protein and transglutaminase

Safety & Health

- Safety Precautions and Handling

Enzymes are proteins. Inhalation of dust or aerosols may induce sensitization and cause allergic reactions in sensitized individuals. Prolonged contact with some enzymes may irritate the skin, eyes and mucous membranes. The product may create easily inhaled aerosols if splashed or vigorously stirred. Spilled product may dry out and create dust. Spilled material should be flushed away with water. Avoid splashing. Left over material may dry out and create dust. Wear suitable protective clothing, gloves, eye and face protection, and wash contaminated clothes. A Material Safety Data Sheet is supplied with all products for further information on how to handle the product safely.

Packaging & Availability

- Packaging

- Cardboard box with PE inliner, 10 kg net

Storage & Handling

- Storage & Stability

When kept cool and dry in original, sealed packaging activity loss is less than 15 % in 12 months The product is susceptible to oxidation and should be used quickly after opening of the package.