Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Food Ingredients Functions

- Ingredients

- Water, Glycerol, Lactase

- Technologies

- Product Families

- Origin

Non-pathogenic Saccharomyces marxianus var lactis strain (GRAS Status)

Features & Benefits

- Labeling Claims

- Food Ingredients Features

- Characteristics

Liquid yeast ß-galactosidase (E.C. 3.2.1.23, ß-D-galactoside galacto hydrolase) with wide pH and temperature range. The enzyme is dissolved in a yellowish liquid containing glycerol. Due to a special purification step the preparation has no side activities which could cause off-flavors in the milk upon long storage time.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Applications

- Removal of lactose from liquid food and feed

- Digestive preparations for ß-galactosidase insufficient individuals

- Prevents crystallization of lactose in ice-cream and “dulce-deleche”- style products

- Dosage

- A typical dose rate is 0.02 ml Dairyzym Y 50 L per 1 gram of lactose. But the optimal dosage depends greatly on process conditions and may therefore deviate from the suggested dosage. Finding the optimal dosage for each individual process is a matter for the customer.

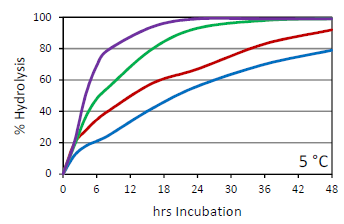

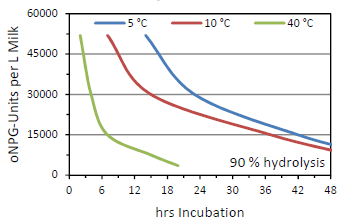

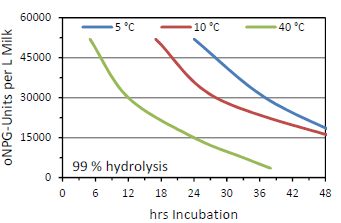

- At a temperature of 5°C hydrolysis of virtually all lactose in milk can be achieved with typical dose rates of 0.8 – 1.2 ml per liter in 24 hours.

- At a temperature of 40°C the hydrolysis takes only 6 hours but undesired microbial growth may occur. In sweetened condensed milk 0.3-0.4 ml per liter milk effectively prevent a sandy mouth feel.

Properties

- Physical Form

- Appearance

- Liquid

- Chemical Properties

- Typical Properties

- Microbiological Values

- Nutritional Information

- Nutritional Data [approximate data per 100 g]

Property Method Dimension Target Energy calculated kcal/100 g 235 - 260 Energy calculated kJ/100 g 917 - 1014 Protein calculated g/100g 4 - 5 Carbohydrates calculated g/100g 54 - 60 of which sugars calculated g/100g 0 Fat calculated g/100g 0 of which saturated fatty acids calculated g/100g 0 Dietary fiber calculated g/100g 0 Sodium (Na) calculated mg/100g 0 Salt (Sodium x 2.5) calculated g/100g 0

| Value | Units | Test Method / Conditions | |

| Arsenic Content | max. 3 | mg/kg | AAS |

| Cadmium Content | max. 0.5 | mg/kg | AAS |

| Lead Content | max. 5 | mg/kg | AAS |

| Mercury Content | max. 0.5 | mg/kg | AAS |

| Value | Units | Test Method / Conditions | |

| Density | 1,05 - 1,15 | g/ml | — |

| Lactase neutral | min. 54000 | oNPG-u/g | oNPG hydrolysis |

| Value | Units | Test Method / Conditions | |

| Escherichia coli | Negative | cfu/25g | M. Colif.-Agar 36°C/48h |

| Salmonella | Negative | cfu/25g | DIN EN ISO 6579 |

| Total Plate Count | max. 1000 | cfu/g | DIN EN ISO 4833 |

| Yeast and Molds Count | max. 100 | cfu/g | ASU L 01.00-37 |

| Value | Units | Test Method / Conditions | |

| Energy | 917 - 1014 | kJ/100 g | Calculated |

| Protein | 4 - 5 | g/100g | Calculated |

| Carbohydrates | 54 - 60 | g/100g | Calculated |

| Sugars | 0 | g/100g | Calculated |

| Fat Content | 0 | g/100g | Calculated |

| Saturated Fatty Acids | 0 | g/100g | Calculated |

| Dietry Fibre | 0 | g/100g | Calculated |

| Sodium Content | 0 | mg/100g | Calculated |

| Salt (Sodium x 2.5) | 0 | g/100g | Calculated |

Regulatory & Compliance

- Certifications & Compliance

- Regulatory Information

Allergen Information: No substances or products causing allergies or intolerances according to Regulation 1169/2011/EG, Annex II

Health Information: The products are suitable for human consumption if used accordingly to recommendations and officially allowed to be sold within Germany and the EU. The product is food grade and conforms with the current european food law.

GMO: This product is not a genetically modified organism (GMO), nor does it contain any GMO or any recombinant DNA. All the non-enzymatic constituents of the product (e.g. carriers, stabilizing agents, free-flowing agents etc.) originate from non-genetically modified sources. Due to the ubiquitous presence of GMO organisms, absence of minor traces of GMO material cannot be guaranteed, but in any case, the content of unintentionally present GMO material will be below 0.9 %, in accordance to EU guidelines 1830/2003 and 1829/2003. The product is used as processing aid in food manufacturing processes, and therefore labeling is not required in the EU. National regulations must be observed.

Product suitability:

Yes No Vegetarian X Vegan X BSE/TSE Information: The mentioned product does not represent a BSE (Bovine Spongiform Encephalopathy) and/or TSE (Transmissible Spongiform Encephalopathy) risk.

Irradiation: Neither the product nor its ingredients have been treated with ionizing radiation according to Directive 1999/2/EC and 1999/3/EC.

Nanoparticles: The product does not contain ingredients in the form of engineered nanomaterials as defined in Regulation (EU) 2015/2283.

Contamination/Residues: The product complies with: Regulation (EC) No 396/2005 and its amendments regarding maximum levels for pesticide residues in foodstuffs. Regulation (EC) No 1881/2006 and its amendments regarding especially maximum levels for heavy metals, mycotoxins, dioxins and PCB in foodstuffs.

Conformity of the Packaging: The packaging material complies with the provisions of Regulation (EC) No 1935/2004 and Regulation (EU) No 10/2011.

Technical Details & Test Data

- Temperature/pH activity data

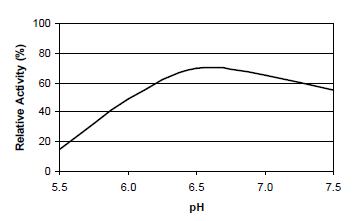

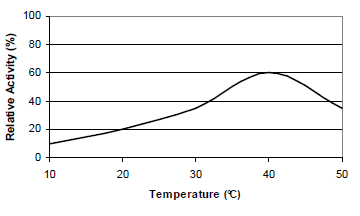

Yeast-ß-galctosidase 54,000 oNPG-U/g (min. 5,000 NLU/g) pH optimum 6.3 – 6.8 pH stability 6.0 - 7.5 Temperature optimum 35 - 40 °C at pH 6.5 Temperature stability very stable below 50°C 1 unit lactase is defined as the enzyme quantity that liberates 1 μMol of o-nitrophenol per minute from o-nitrophenylgalactopyranoside at pH 6.5 and 37°C.

Fig. 1: pH-activity curve for Dairyzym Y 50 L (37 °C, 4 h)

Fig. 2: Temperature-activity curve for Dairyzym Y 50 L (pH 6.5, 4 h)

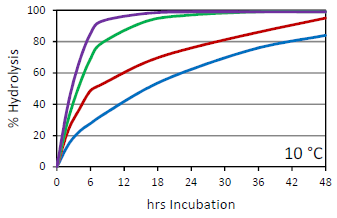

Hydrolysis data

Fig. 3: Lactose hydrolysis at 5 °C with different dosages

Fig. 4: Lactose hydrolysis at 10 °C with different dosages

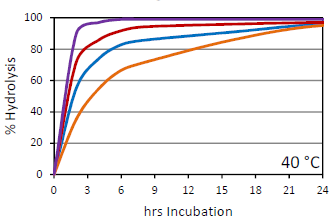

Fig. 5: Lactose hydrolysis at 40 °C with different dosages

Fig. 6: Applied dosages in Fig. 3-5

Fig. 7: Needed time to reached 90 % hydrolysis with different dosages at different temperatures

Fig. 8: Needed time to reached 99 % hydrolysis with different dosages at different temperatures

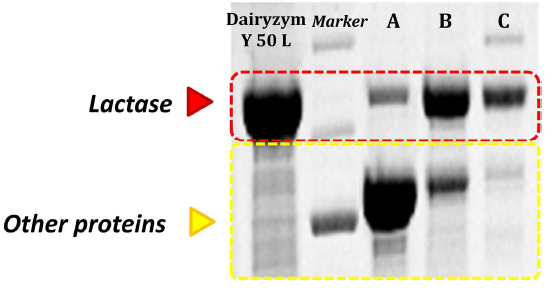

Enzyme purity

Beside Lactase unmodified yeast also produces other enzymes. These contaminating enzymes could bring unfavorable effects, like taste defects, to your final product. Dairyzym Y 50 L is very pure and is produced by unique technology.

Fig. 8: Polyacrylamid gel analysis of enzyme proteins in various lactase preparations.

Information on application

Lactose-free milk

Pasteurize the fresh milk and adjust the temperature to fit the chosen time, temperature

and enzyme concentration relationship. To prevent undesirable microbial growth we advise to hydrolyze and treat the milk below 10°C.

Agitate the milk to assure proper mixing of the enzyme and to keep the solution homogeneous.

Add the required amount of Dairyzym Y 50 L to the milk according to the chosen incubation time and temperature. At 5-10 °C milk temperature 1 ml Dairyzym Y 50 L is sufficient to completely hydrolyze the lactose in the milk.

At the expected end of the hydrolysis one should again determine the degree of hydrolysis. When the desired degree of hydrolysis is achieved, the milk is ready for further processing. The milk can now be pasteurized or preferably UHT-treated and packed.Sweetened condensed milk

Raw milk is clarified and standardized, and then is heated to 85-90 °C for several seconds. This heating destroys osmophilic and thermophilic microorganisms, decreases fat separation, inhibits oxidative changes and inactivates lipolytic and proteolytic enzymes.

After the heat treatment 0.4 ml Dairyzym Y 50 L is added per liter raw milk.

The milk is then concentrated at low temperatures by vacuum evaporation. In case milk evaporation, the boiling point is lowered to approximately 40-45°C. This results in little to no cooked flavor and perfect conditions for the lactose hydrolysation. The milk is concentrated to 30-40 % total solids.

Although sugar may be added before evaporation, post evaporation addition is recommended to avoid undesirable viscosity changes during storage. Enough sugar is added so that the final concentration of sugar is approximately 45%.

The sweetened evaporated milk is pasteurized and then cooled and packaged in smaller containers, such as cans, for retail sales and bulk containers for industrial sales.

The applied lactase enzyme completely hydrolyses the lactose of the milk. For this reason lactose crystallization is not longer possible and further preventive measures like seeding with powdered lactose crystals is not required.Yogurt (lactose-free)

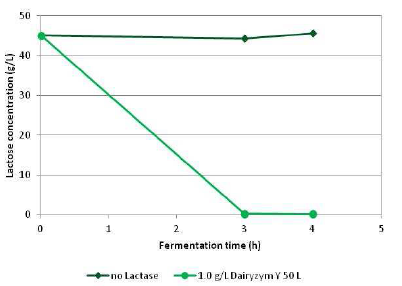

The yeast lactase is very active at typical yogurt fermentation temperatures of 30-40 °C (Fig. 5). For this reason Dairyzym Y 50 L can easily be applied to produce lactose-free yogurt. A dosage of 1 g per liter of yogurt milk will hydrolyse all lactose within the fermentation time (Fig. 9).Fig. 9: Lactose hydrolysation during yogurt fermentation (42 °C)

Safety & Health

- Safety Precautions and Handling

Enzymes are proteins. Inhalation of dust or aerosols may induce sensitization and cause allergic reactions in sensitized individuals. Prolonged contact with some enzymes may irritate the skin, eyes and mucous membranes. The product may create easily inhaled aerosols if splashed or vigorously stirred. Spilled product may dry out and create dust. Spilled material should be flushed away with water. Avoid splashing. Left over material may dry out and create dust. Wear suitable protective clothing, gloves, eye and face protection, and wash contaminated clothes. A Material Safety Data Sheet is supplied with all products for further information on how to handle the product safely.

Packaging & Availability

- Packaging Type

- Packaging

PE bottle, 25 kg net or 1,000 kg IBC

Storage & Handling

- Storage & Shelf Life

Min. 12 month if Stored cool and dry, activity loss on storage less than 10% per year