Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Enzyme Type

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Invertase

- Food Additive Number

- E 1103, INS 1103

- Technologies

Features & Benefits

- Food Ingredients Features

Applications & Uses

- Markets

- Food & Nutrition Applications

Properties

- Appearance

- Granulated powder

- Chemical Properties

- Typical Properties

- Microbiological Values

- Nutritional Information

- Nutritional Data

Description Value Unit/100g Energy 1.615 kJ Energy 386 kcal Fat 0.1 g of which: saturated fatty acids (FA) 0 g Carbohydrates 70 g of which: Sugar 2 g Fiber 0 g Proteinn (N x 6,25) 25 g Salt (Sodium x 2.5) 5 g Sodium 2 g organic acid 0 g

| Value | Units | Test Method / Conditions | |

| Arsenic Content | max. 3 | mg/kg | AAS |

| Cadmium Content | max. 0.5 | mg/kg | AAS |

| Lead Content | max. 5 | mg/kg | AAS |

| Loss on Drying | max. 14 | g/100g | drying oven; 3h 105°C |

| Mercury Content | max. 0.5 | mg/kg | AAS |

| Value | Units | Test Method / Conditions | |

| Invertase | 190000 - 210000 | u/g | according to Sumner |

| Value | Units | Test Method / Conditions | |

| Escherichia coli | NEGATIV | cfu/g | M. Colif.-Agar 36°C/48h |

| Salmonella | Negative | cfu/25g | DIN EN ISO 6579 |

| Total Plate Count | max. 10000 | cfu/g | DIN EN ISO 4833 |

| Value | Units | Test Method / Conditions | |

| Energy | 1.615 | kJ/100 g | — |

| Fat Content | 0.1 | g/100g | — |

| Saturated Fatty Acids | 0 | g/100g | — |

| Carbohydrates | 70 | g/100g | — |

| Sugar | 2 | g/100g | — |

| Fibre | 0 | g/100g | — |

| Protein (N x 6.25) | 25 | g/100g | — |

| Salt (Sodium x 2.5) | 5 | g/100g | — |

| Sodium Content | 2 | g/100g | — |

| Organic Acid | 0 | g/100g | — |

Regulatory & Compliance

- Regulatory Information

Allergen Information: contains the allergen milk and lactose according to Regulation 1169/2011/EG, Annex II

Health Information: The products are suitable for human consumption if used accordingly to recommendations and officially allowed to be sold within Germany and the EU. The product is food grade and conforms with the current european food law.

GMO: This product is not a genetically modified organism (GMO), nor does it contain any GMO or any recombinant DNA.

All the non-enzymatic constituents of the product (e.g. carriers, stabilizing agents, free-flowing agents etc.) originate from non-genetically modified sources. Due to the ubiquitous presence of GMO organisms, absence of minor traces of GMO material cannot be guaranteed, but in any case, the content of unintentionally present GMO material will be below 0.9%, in accordance to EU guidelines 1830/2003 and 1829/2003. The product is used as processing aid in food manufacturing processes, and therefore labeling is not required in the EU. National regulations must be observed.Product suitability:

Yes No Vegetarian X Vegan X BSE/TSE Information: The mentioned product does not represent a BSE (Bovine Spongiform Encephalopathy) and/or TSE (Transmissible Spongiform Encephalopathy) risk.

Irradiation: Neither the product nor its ingredients have been treated with ionizing radiation according to Directive 1999/2/EC and 1999/3/EC

Nanoparticles: The product does not contain ingredients in the form of engineered nanomaterials as defined in Regulation (EU) 2015/2283.

Contamination/Residues: The product complies with: Regulation (EC) No 396/2005 and its amendments regarding maximum levels for pesticide residues in foodstuffs. Regulation (EC) No 1881/2006 and its amendments regarding especially maximum levels for heavy metals, mycotoxins, dioxins and PCB in foodstuffs.

Conformity of the Packaging: The packaging material complies with the provisions of Regulation (EC) No 1935/2004 and Regulation (EU) No 10/2011.

Technical Details & Test Data

- Enzyme System for the Production of Bee Food

- Production of bee food with optimum characteristics

- Reliable and cost effective conversion of sucrose

- Specific sugar composition achievable

- No unwanted color formation or by-products

There are times when the beekeeper needs to rely on artificial honey, for instance for facilitating the survival of bees during the winter or for forage gap feeding. Ideally, such a bee food syrup should feature a specific sugar composition (one third sucrose should remain, meaning roughly 70% inversion), a neutral color and the absence of unwanted by-products. Sweetase 200 P enables the reliable and controlled hydrolysis of sucrose while avoiding the formation of harmful by-products. This way, bee food with the optimum characteristics can be produced.

Bee Food

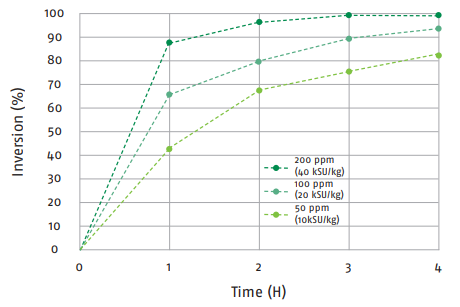

Sweetase 200 P catalyzes the inversion of sucrose to equal parts of fructose and glucose. It originates from Saccharomyces cerevisiae. By adjusting the enzyme dosage and/or the reaction time, the inversion of sucrose can be precisely adjusted (see Fig. 1).

Fig. 1: Inversion [%] of a 66% (w/v) sucrose solution at pH 5 and 60°C using Sweetase 200 P.

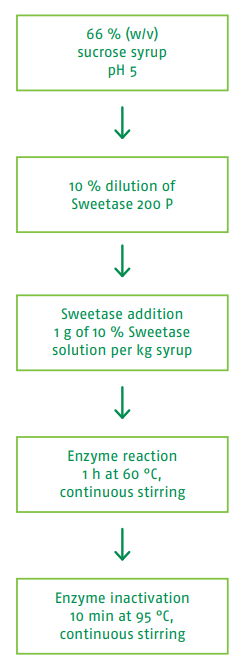

Application of Sweetase 200 P

1. A 66 % (w/v) sucrose solutions is the starting material for the sucrose inversion. After the complete dissolution of sucrose, the pH is adjusted to a value of 5.

2. Prepare a 10 % enzyme solution. Thus, 0.1 kg Sweetase 200 P is filled up with water to a total amount of 1 kg.

3. To this syrup, add 1 g of the 10 % - Sweetase 200 P solution per kg syrup is added. This corresponds to 20.000 Sumner Units.

4. Stirring continuously, heat the syrup to 60 °C. This temperature is then kept for 1 hour, as an example, to obtain an inversion of roughly 70 % (see Fig. 1 above).

5. Afterwards, the enzyme is inactivated by increasing the temperature to 95 °C for 10 minutes.

- Enzyme System for the Production of Invert Sugar Syrup

- Reliable and cost effective conversion of sucrose

- Higher sweetening power Improved taste

- Longer shelf-life of food products

- No unwanted color formation or by-products

Invert sugar syrup is popularly used in the confectionary and baking industry. The resulting syrup, containing equal parts of glucose and fructose, has superior properties compared to glucose or sucrose syrups. Invert sugar syrup is known for a higher sweetening power as well as a mild and fruity taste. Besides, the shelf-life of the final products (such as confectionary, cream fillings, pastries) is increased. Sweetase 200 P provides a reliable and cost-efficient inversion of sucrose without the formation of any by-products.

Invert sugar syrup

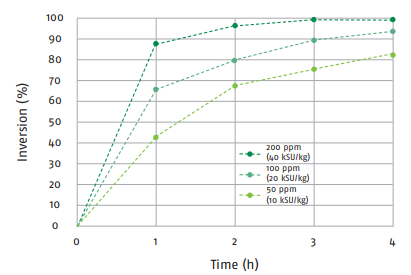

Sweetase 200 P catalyzes the inversion of sucrose to equal parts of fructose and glucose. It originates from Saccharomyces cerevisiae. By adjusting the enzyme dosage and/or the reaction time, the inversion of sucrose can be maximized (see Fig. 1).

Fig. 1 Inversion [%] of a 66% (w/v) sucrose solution at pH 5 and 60°C using Sweetase 200 P.

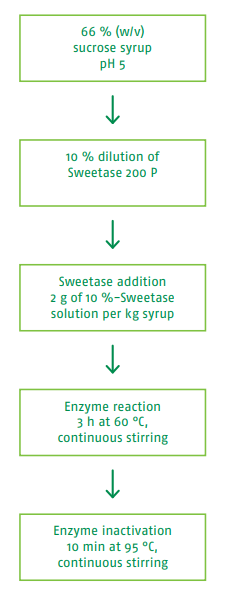

Application of Sweetase 200 P

1. A 66 % (w/v) sucrose solutions is the starting material for the sucrose inversion. After the complete dissolution of sucrose, the pH is adjusted to a value of 5.

2. Prepare a 10 % enzyme solution. Therefore, 0.1 kg Sweetase 200 P is filled up with water to a total amount of 1 kg.

3. To this sugar syrup, an amount of 2 g of the 10% - Sweetase 200 P solution per kg syrup is added. This corresponds to 40.000 Sumner-Units.

4. Under continuous stirring, the syrup is heated up to 60°C. This temperature is then kept for 3 hours to obtain an inversion of 100% (see Fig. 1 above).

5. Afterwards, the enzyme is inactivated by increasing the temperature to 95°C for 10 minutes.

Packaging & Availability

- Packaging

Cardboard box with PE-Inliner, 15 kg net weight

Storage & Handling

- Storage & Shelf Life

Min. 18 months if stored cool (< 25°C) and dry in c losed original packing