Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

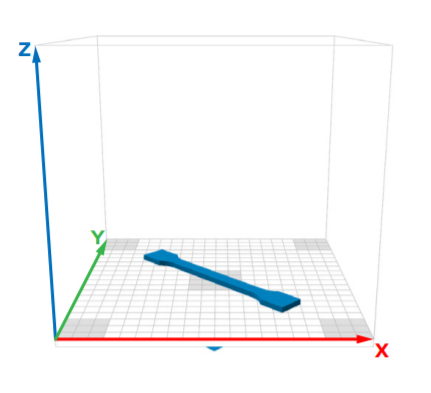

- TURBINE.

Fully functional prototype of the wind turbine 3D printed with Z-ASA Pro filament. The model stays unaffected by the changing temperature, humidity and light, allowing for a prolonged field testing.

-

Weather resistance

Weather resistance of Z-ASA Pro filament allows for testing your models outdoors. 3D printed, highly durable prototypes and final parts can work even in direct sunlight.

- UV stable

Z-ASA Pro won’t deform or fade when exposed to the heat. Conduct thorough outdoor tests, no matter the changing temperature and direct sunlight.

- Low shrinkage and warping

The polystyrene-based filament is also available for Zortrax M300, which makes it ideal for large casings and parts. Its low shrinkage and warping guarantee dimensionally accurate 3D printing.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Models tested outside

- Objects required to be resistant to the changing weather conditions and UV light

- Functional outdoor prototyping

- Large-scale models

- Automotive parts

Properties

- Physical Form

- Mechanical Properties

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 24.21 | MPa | ISO 527:1998 |

| Breaking Stress | 21.94 | MPa | ISO 527:1998 |

| Elongation (Max Tensile Stress) | 2.64 | % | ISO 527:1998 |

| Elongation (Break) | 2.76 | % | ISO 527:1998 |

| Bending Stress | 45.6 | MPa | ISO 178:2011 |

| Flexural Modulus | 1.36 | GPa | ISO 178:2011 |

| Izod Impact (Notched) | 3.81 | kJ/m2 | ISO 180:2004 |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 80.99 | °C | ISO 11357-3:2014 |

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (Load 10 kg Temperature 220°C) | 74.91 | g/10 min | ISO 1133:2006 |

| Hardness | 68 | Shore D | ISO 868:1998 |

| Specific Density | 1.176 | g/cm³ | ISO 1183-3:2003 |

Technical Details & Test Data

- Test Data

Samples of Z-ASA Pro used to carry out the tests were built on Zortrax M200. The general print parameters utilized are noted below

- Z-SUITE: v2.2.0.0

- Layer thickness: 0.19 mm;

- Quality: High;

- Seam: Normal;

- Infill: Solid,

- Fan Speed: Auto;

- Surface Layers:

- Top: 7 (default);

- Bottom: 4 (default);

Packaging & Availability

- Available Colours

- Graphite

- Pure Black

- Pure White