"Nanjing Capatue Chemical Co., Ltd (hereinafter referred to as ""Capatue Chemical"")is a fine chemical enterprise focused on the R&D, production and marketing of polymer additives . It was founded in 2007 and located at one of the major chemical industry base of China, Nanjing. Nanjing is also the capital of Jiangsu province in Eastern China and it is about 300km far from Shanghai. It has a prominent place in Chinese history and culture, having been the capital of China for several periods. Nanjing is an old city with a prominent place in Chinese history and culture, having been the capital of China for several periods and its present name means ""Southern Capital"".With nearly 10 years of development, Capatue Chemical has formed a business structure including two technical business core: Organofunctional Silane and Organometallic Titanate ( Aluminate & zirconate); and two derivatives business: coating additives (adhesion promoter & dispersing aid) and silane crosslinking material (porous polymer carrier, dry silane, formulated silane and one-step silane soaking XLPE compounding technology).

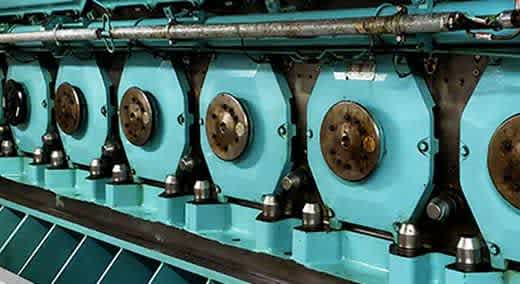

Our products are widely used in various resin-based composites and resin coating applications, offering our value-added products and services to thousands of customers in China and all of the world! The three main application areas are plastic & rubber, coating & sealant and other resin-based composite materials: 1. Plastic & Rubber application: including tires, shoe sole, other rubber goods, modified plastics (mineral filled, fiber glass reinforced, flame retardant, etc.), HFFR, XLPE, wire and cable, and inorganic mineral filler pretreatment & surface coating; 2. Coating & Sealant: including paint, coating, ink, colorant & pigment surface treatment, metal surface treatment, adhesive, sealant and other resin coating; 3. Other resin-based composite: including fiber glass, artificial quartz stone, resin sand casting, abrasive & grinding material, electrical insulation, textile auxiliaries."