Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Key Features & Benefits

- Flexible cure temperature 50-150 °C

- Service temperature up to 150 °C (after post-cure, or high temperature ramped cure)

- 21 days out-life at room temperature

- 12 months storage life at -18 °C

- Good tack and drape

- Toughened

- Excellent surface finish

- Available on a range of reinforcement fabrics

Applications & Uses

- Applications

- Cure Method

- Composites End Use

- Composites Processing Methods

Technical Details & Test Data

- Processing & Curing

To optimize surface finish for autoclave cure:

● Vacuum debulking is recommended after the 1st or 2nd ply and then every subsequent

4-5 plies.

● A suitable debulking stage is 30 minutes at room temperature using a perforated release

film and breather fabric.

● For the final cure a non-perforated release film should be used with a layer of breather

fabric.The times indicated in the tables below are minimum cure times. If in doubt regarding the accuracy of the temperature controller or process it is recommended to add extra time.

● We recommend a low autoclave pressure e.g. 3.5 bar (50 psi)

● Cure times may need to be extended to account for thermal lag in large tools.Initial Cure

Suggested initial cure cures (on-pattern) are shown below:

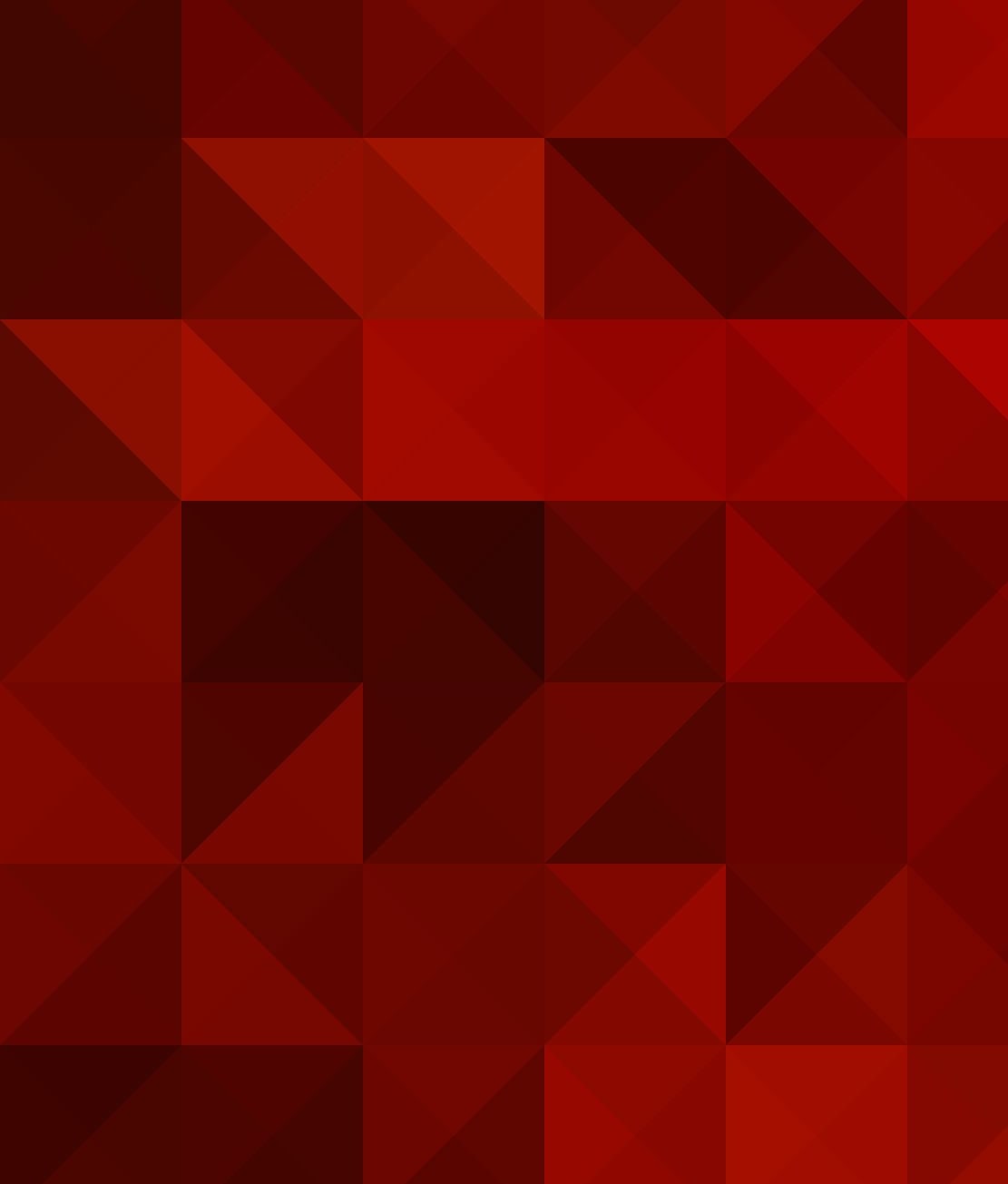

Cure temperature Ramp rate Minimum cure time Glass transition temperature Tg, onset E’ Glass transition temperature Tg, peak tan δ 50 °C 1 °C/min 40 hours 57 °C 74 °C 55 °C 1 °C/min 24 hours 63 °C 81 °C 65 °C (recommended) 1 °C/min 12 hours 81 °C 101 °C Suggested initial cure cycle (ramp rate 1 °C/min, dwell 12 hours at 65 °C):

Post-Cure

Suggested free-standing post-cures (off-pattern):

Post-cure

temperatureRamp rate Minimum cure time Glass transition DMA temperature Tg, onset E’ Glass transition DMA temperature Tg, peak tan δ 130 °C 0.5 °C/min 1 hour 141 °C 170 °C 150 °C 0.5 °C/min 1 hour 158 °C 176 °C - Ramp rate for post-cure should not exceed 0.5 °C/min.

- Care should be taken to heat slowly and steadily to avoid distortion during post-cure, larger molds may require additional support.

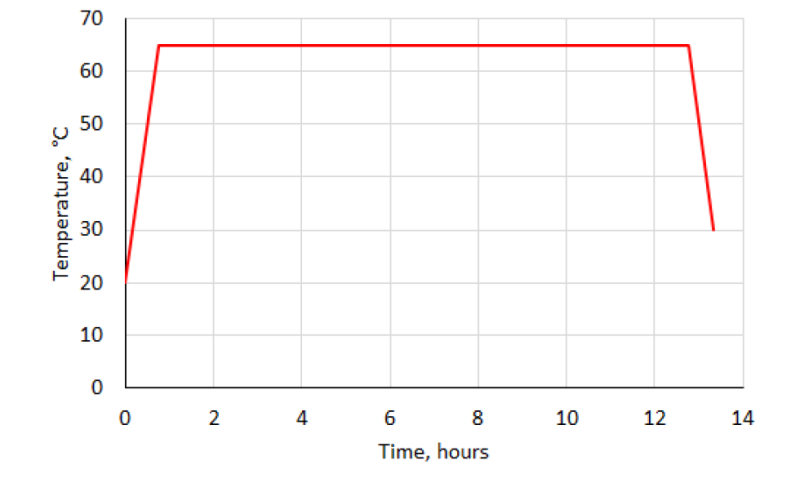

Suggested post-cure schedule (ramp rate 0.5 °C/min, dwell 1 hour at 150 °C):

Single-shot cure

Suggested single-shot cure options for faster turnaround tooling where thermal expansion is not critical and pattern is not sensitive to thermal shock (e.g. metallic patterns).

Cure

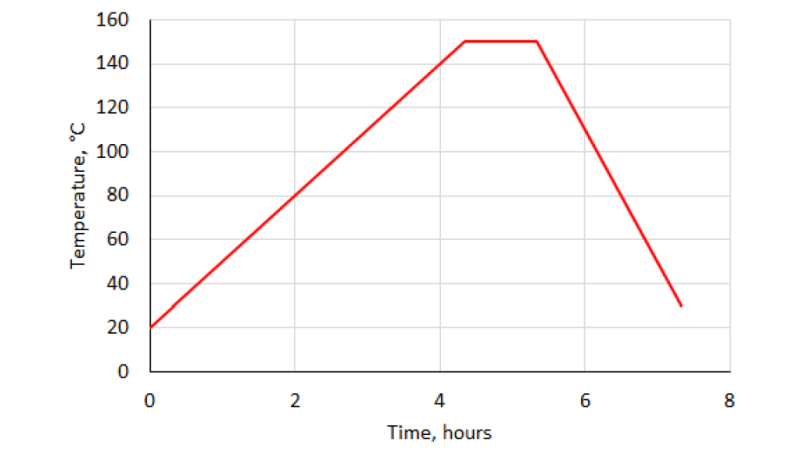

temperatureRamp rate* Minimum cure time Glass transition temperature Tg, onset E’ Glass transition temperature Tg, peak tan δ 130 °C 1 °C/min 1 hour 142 °C 181 °C 150 °C 1 °C/min 1 hour 157 °C 179 °C Suggested single-shot cure schedule (ramp rate 1 °C/min, dwell 1 hour at 150 °C):

- Available Products

Evopreg® EPT120 prepregs are available with a wide range of reinforcements, including woven, non-crimp stitched and unidirectional fabrics. Standard products are as follows:

- Carbon 205 g/m² 2x2 twill 3K surface ply

- Carbon 650 g/m² 2x2 twill 12K bulking ply

For other reinforcements including glass and ampliTex™ flax please contact us.

Safety & Health

- Health & Safety

Please refer to the Safety Data Sheet (SDS) before use. This material contains epoxy resin and fibers which can cause irritation to skin and eyes and allergic reactions. Wear appropriate PPE including overalls and impervious gloves, and ensure adequate ventilation. Exothermic reactions can occur when curing epoxy resins, and particular care must be taken when curing thick laminates.Please refer to the Safety Data Sheet (SDS) before use. This material contains epoxy resin and fibers which can cause irritation to skin and eyes and allergic reactions. Wear appropriate PPE including overalls and impervious gloves, and ensure adequate ventilation. Exothermic reactions

can occur when curing epoxy resins, and particular care must be taken when curing thick laminates.

Packaging & Availability

- Packaging

The material is typically delivered in rolls and with a silicone coated release paper on the bottom and a polythene release film on the top. Typical packaging - 76 mm (3”) diameter cardboard core, polythene bag, reusable cable ties, cardboard box and end supports. Where relevant, multiple boxes are typically stacked on a standard wooden pallet, strapped and covered with stretch wrap. Other packaging may be available on request. We recommend retaining the boxed packaging to protect the material during storage.

Storage & Handling

- Shelf Life

- 12 Months

- Storage

The material should ideally be stored in a freezer at -18°C and sealed in a polythene bag. To protect the material, we recommend storing it in its original box with the end supports. To avoid moisture condensation, allow the material to defrost fully and reach room temperature before opening the polythene bag. Typical thaw time for a full roll is 4-6 hours. Keep the material sealed in a polythene bag when not in use to prevent moisture absorption. Out-life at room temperature is 21 days. Storage life at -18°C is 12 months.