Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- CASE Ingredients Functions

- Composite Materials Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

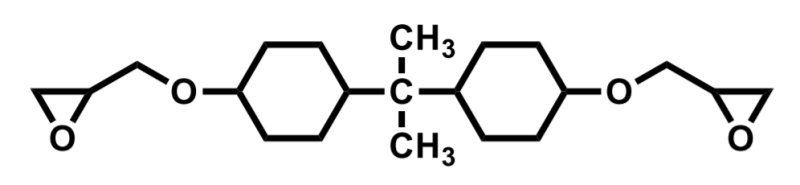

- Molecular Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Features

- Highly adhesive to metal, porcelain, concrete

- Excellent insulation property

- High heat resistance

- High chemical resistance

- High water resistance

- Product Highlights

- Liquid type (easy to handle)

- Excellent Tranparency even after full-curing

- Adhesion

- High Photo cure rate

- Low chlorine level

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Cure Method

- Coating Type

- Plastics & Elastomers End Uses

- Usage & Application

- Photocure process (UV/LED)

- LED/OLED encapsulant

- LED reflector

- Adhesives for optical devices, electro-optic assemblies, and laser components.

Properties

- Physical Form

- Appearance

- Colorless liquid

- Typical Physical Properties

- Physical Properties

- Typical Properties

- Properties Formulation

Value Unit Method jER™ YX8000D 100 - phr Other company’s hydrogenated bisphenol A type epoxy - 100 Anhydride curing agent (Methylhexahydrophthalic anhydride/Hexahydrophthalic anhydride = 70/30) 89 77 phr Curing accelerator (Methyltributylphosphonium dimethylphosphate) 1 1 phr Gel time @ 120 °C 30 36 Curing condition 100°C/3h + 130°C/3 h

Cured State Properties Tg (tanδ) 135 - °C Dynamic Mechanical Analysis

Elastic modulus @ 30 °C 3.4 - GPa Dynamic Mechanical Analysis

Elastic modulus @ 220 °C 17 - MPa Dynamic Mechanical Analysis

Tg 136 110 Thermo Mechanical Analysis

Coefficient of Thermal Expansion (α1) 68 75 ppm Thermo Mechanical Analysis

Coefficient of Thermal Expansion (α2) 172 186 ppm Thermo Mechanical Analysis

Moisture absorption rate

72hr 0.8 0.9 % 85°C 85%RH

168hr 0.83 0.92 % Light resistance (Weathermeter, 0.4kw/m^2)

Yellowness index

0hr 1 1 - 168hr 7 16 - Light transmittance at 360 nm

0hr 86 85 % 168hr 53 35 %

| Value | Units | Test Method / Conditions | |

| Refractive Index (589nm) | 1.50 | — | D line |

| Value | Units | Test Method / Conditions | |

| Density (at 25°C) | 1.1 | g/cm3 | Density Meter (Vibration type) |

| Value | Units | Test Method / Conditions | |

| Epoxy Equivalent Weight (WPE) | 175 - 195 | g/eq | Potentiometric Titration |

| Chloride Content | max. 1200 | ppm | Potentiometric Titration |

| Viscosity (at 25°C) | max. 1500 | mPa.s | Capillary Viscometer |

Technical Details & Test Data

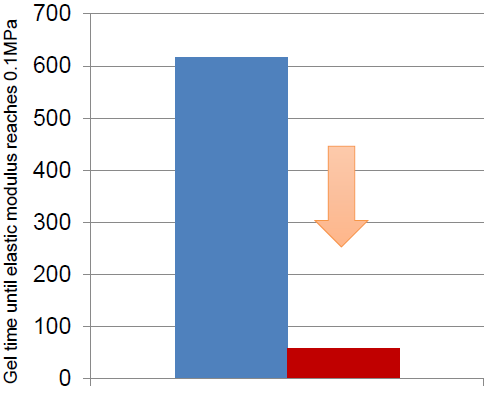

- Photo Curability Data

YX8000D significantly decreases photo curing time to reach sufficient crosslinking reaction level compared to a conventional CER.

CER: Cycloaliphatic epoxy resin

Light source 200mW/cm2, no filter, 25°C

Photo cationic catalyst CPI 100P San Apro Ltd.- Transparency of jER YX8000D

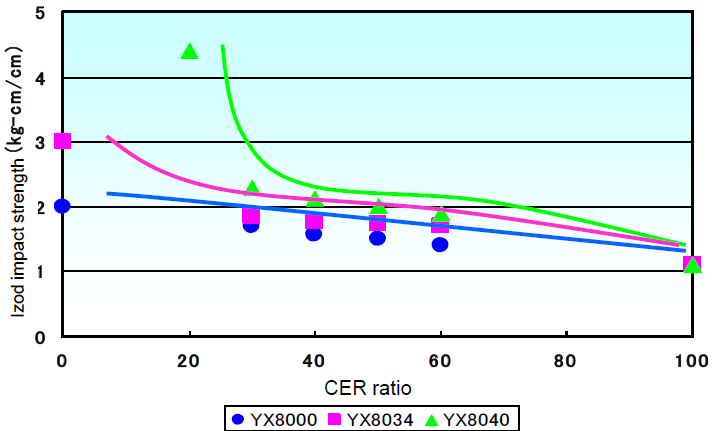

- Izod Impact Strength Data

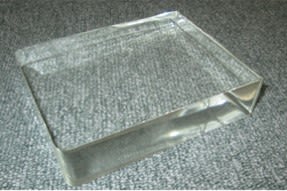

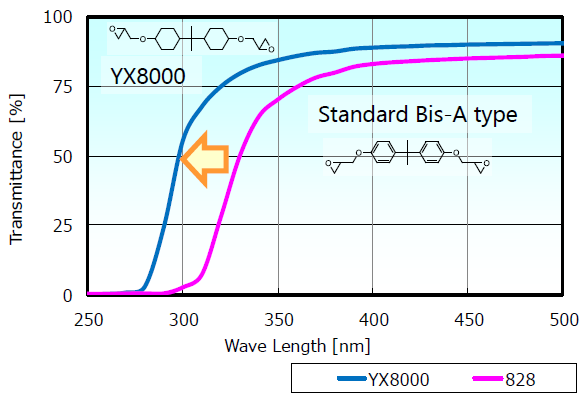

- Transparency Data of YX8000 Series

Transparency data of YX8000*

High transparency can be achieved by YX8000D.

*YX8000 is a former version of YX8000D with higher Cl impurity.

Curing condition: 100°C x 3hr + 130°C x 3hr

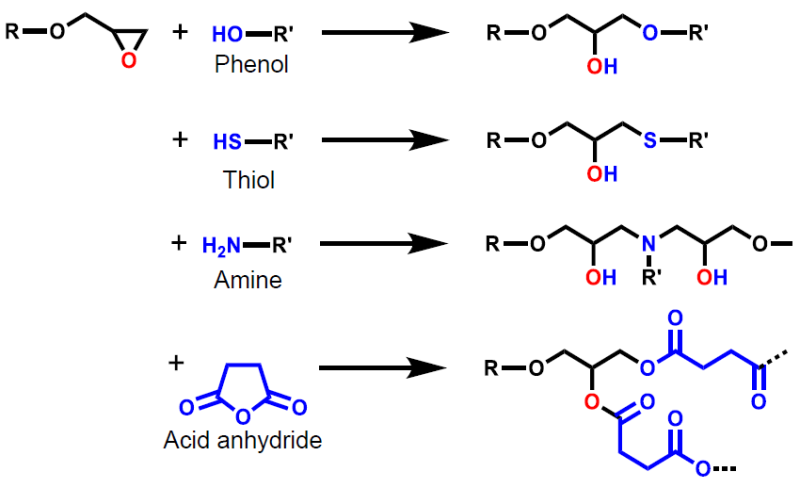

Curing agent: Acid anhydride type- Typical Reactions with Representative Hardeners

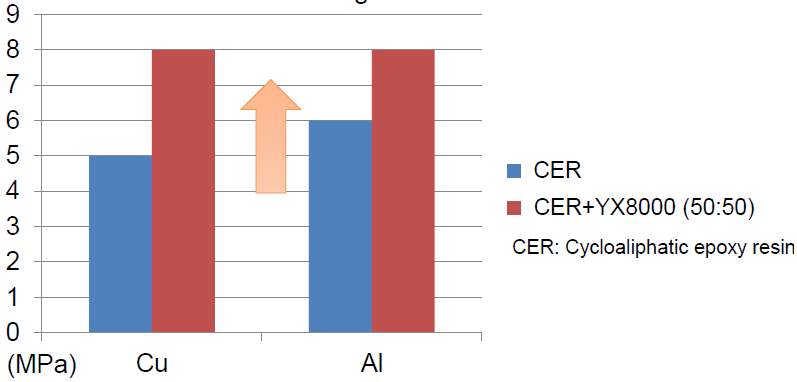

- Adhesion Improvement Data of YX8000

YX8000 addition to CER improves adhesiveness to metal substrates.

*YX8000 is a former version of YX8000D with higher Cl impurity.Share adhesive strength

Curing condition: 100°C x 3hr + 130°C x 3hr

Curing agent: Acid anhydride type

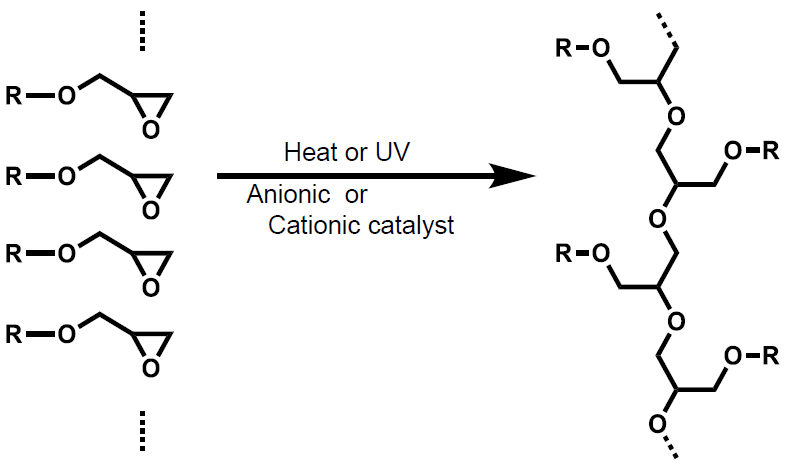

Share adhesive strength test: ISO4587 (JIS K 6850)- Typical Reactions with Self Polymerization

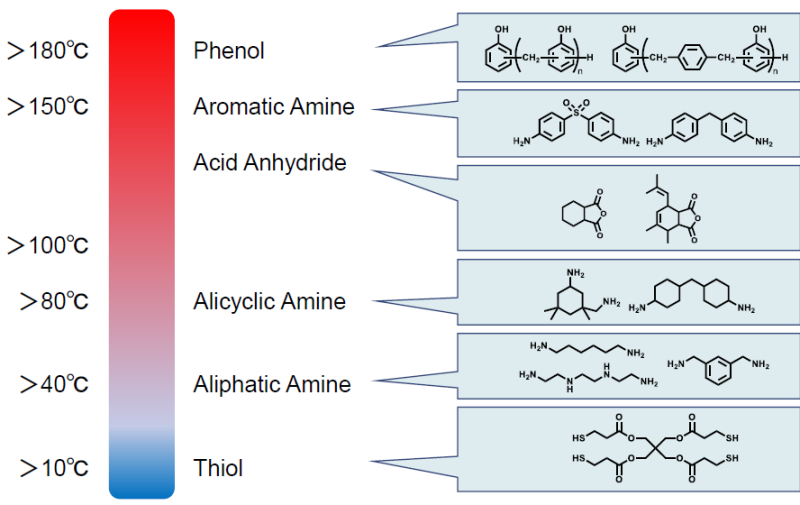

- Selection of Hardeners

Appropriate choice of Hardener for a desired curing temperature

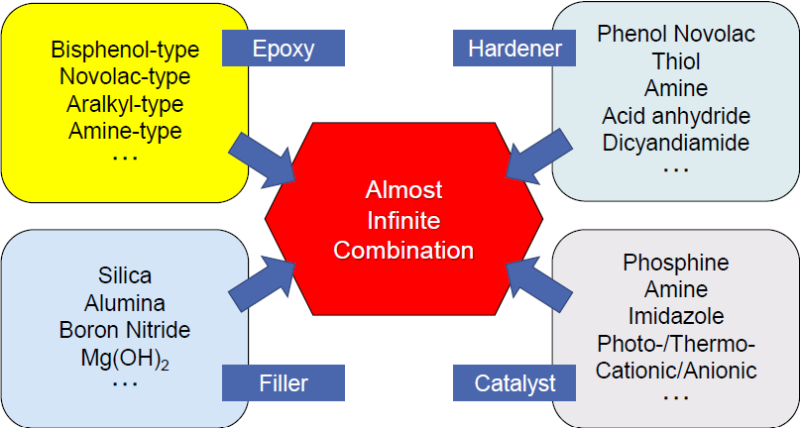

- General Ways to Use Epoxy

- Epoxy resin forms 3D crosslinked network structure

- Abundant choices of Epoxy/Hardener combination

Packaging & Availability

- Packaging Information

- Steel drum with 200 kg net and metal can with 20 kg net

Storage & Handling

- Shelf Life

- 3 months

- Storage and Handling

Carefully read the SDS before using, handling, transporting, storing or disposing. jER™ YX8000D should be stored in tightly closed containers under exclusion of humidity at gentle temperatures. Avoid exposure to direct sunlight. Under these storage conditions the product has a minimum shelf life of three months from date of delivery.