Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

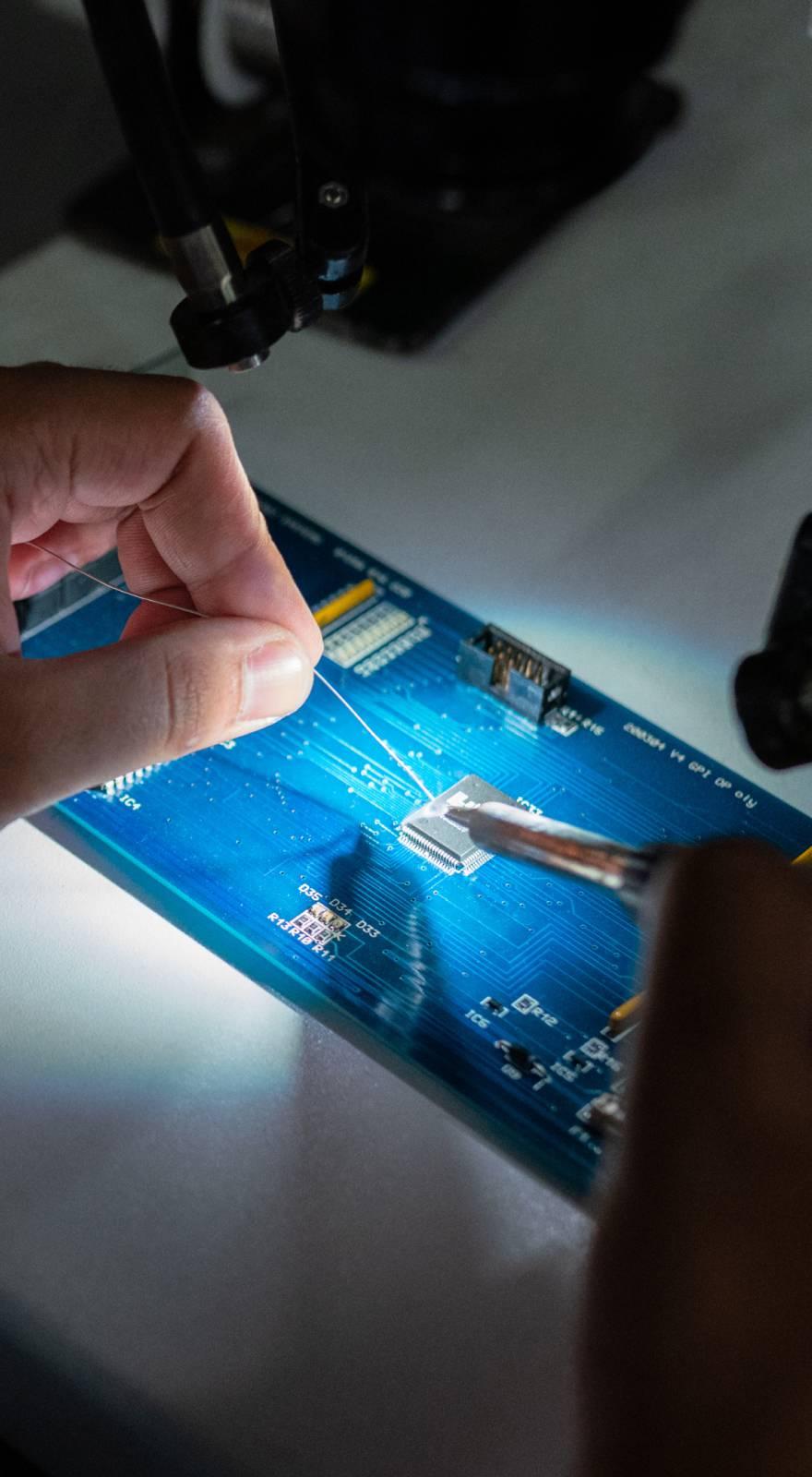

Encapsulation of electrical devices e.g. Solenoids and Transformers.

- Processing methods

Transfer and injection molding.

Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 90 | MPa | ISO 527 |

| Flexural Strength | 160 | MPa | ISO 178 |

| Surface Strain | 1.5 | % | ISO 178 |

| E-Modulus (Flexural Test) | 17’500 | MPa | ISO 178 |

| Impact Strength | 18 | kJ/m2 | ISO 179-1 |

| Notched Impact Strength | 6 | kJ/m2 | ISO 179-1 |

| Value | Units | Test Method / Conditions | |

| Density | 2 | g/cm3 | DIN 53479 |

| Water Absorption (100°C/30Min) | 0,1 | % | ISO 62 |

| Glass Transition Temperature | 140 | °C | ISO 6721 |

| Temperature-Time Limit Ti (Flexural Strength) (20’000H) | 190 | °C | IEC 60216 |

| Thermal Conductivity | 0.6 | W/mK | ISO 8894 |

| Coefficient Of Thermal Expansion (20-105°C) | 16 | ppm/K | ISO 11359-2 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity at 25°C | 10^15 | Ωcm | IEC 60093 |

| Surface Resistivity | 10^17 | Ω 25°C | IEC 60093 |

| Dielectric Loss Factor Tan Δ (At 50Hz,25°C) | 1.2 | % | IEC 60250 |

| Dielectric Constant Εr (At 25°C,50Hz) | 5.5 | 50 Hz | IEC 60250 |

| Electric Strength (3Mm Plate) | 22 | kV/mm | IEC 60243-1 |

| Comparative Tracking Index | 275 | CTI | IEC 60112 |

Storage & Handling

- Shelf Life

12 months at temperatures below 8°C.