Knowde Enhanced TDS

Identification & Functionality

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Industrial Additives Features

- Materials Features

- Key Performance benefits

- Delayed action catalysis

- Wide applicability

Applications & Uses

- Applications

- Applicable Processes

- Compatible Polymers & Resins

- Industrial Additives End Use

- Plastics & Elastomers End Uses

- Product Applications

DABCO® DC 1 can be used in flexible, rigid, and castable polyurethane applications, and has proven extremely versatile in adapting to a particular system's reactivity. Due to its versatility, the use level of the product is dependent on the particular processing needs and application.

Properties

- Physical Form

- Appearance

- Light yellow liquid

- Insoluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (at 25°C) | 400.0 | mPa.s | — |

| Density (at 25°C) | 1.19 | g/cm³ | — |

| Calculated OH number | 689.0 | mg KOH/g | — |

| Flash Point | 63.0 | °C | PMCC |

Technical Details & Test Data

- Test Data

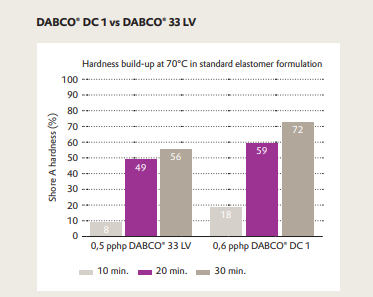

DABCO® DC 1 is a delayed-action catalyst for use in all castable (foamed and high density) polyurethane systems. It has a reactivity similar to standard amine catalysts such as DABCO® 33 LV while also providing a more efficient hardness build-up. DABCO® DC 2 shows a higher reactivity compared to DABCO® DC 1 with shorter pot life and faster return-toservice time. For application sensitive to VOC’s emissions or staining issue, DABCO® DC 5 LE offers similar benefits to DABCO® DC 2 with a lower emission profile. POLYCAT® SA 20 exhibits a similar front-end reactivity as DABCO® DC 1, while meeting low emission requirements and providing an option that does not contain dibutyltin. For situations that require both tin-free and low emission solutions, we offer POLYCAT® SA 5 as a high-performance delayed-action catalyst. DABCO® DC 1, DABCO® DC 2, and POLYCAT® SA 5 are highly efficient and can be used at low levels as co-catalysts in existing formulations to help increase the cure speed of the system without affecting the front-end of the reaction, while maintaining working life.

Storage & Handling

- Storage Conditions

- Shelf life: minimum 12 months. For exact date of expiration, please consider CoA.

- Storage conditions: dry and cool place in factory-packed containers.

- Optimum storage temperature: 10 to 30 °C.