Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- Industrial Additives Functions

Features & Benefits

- CASE Ingredients Features

- Key Performance Benefits

- Promotes rapid gel and tack-free times

- Improves mechanical properties in molded and slabstock foams

- Specialty Catalysts - High Performance

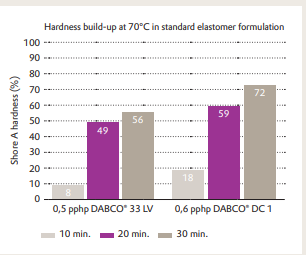

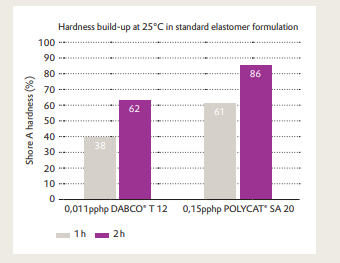

DABCO® DC 1 is a delayed-action catalyst for use in all castable (foamed and high density) polyurethane systems. It has a reactivity similar to standard amine catalysts such as DABCO® 33 LV while also providing a more efficient hardness build-up. DABCO® DC 2 shows a higher reactivity compared to DABCO® DC 1 with shorter pot life and faster return-toservice time. For application sensitive to VOC’s emissions or staining issue, DABCO® DC 5 LE offers similar benefits to DABCO® DC 2 with a lower emission profile. POLYCAT® SA 20 exhibits a similar front-end reactivity as DABCO® DC 1, while meeting low emission requirements and providing an option that does not contain dibutyltin. For situations that require both tin-free and low emission solutions, we offer POLYCAT® SA 5 as a high-performance delayed-action catalyst. DABCO® DC 1, DABCO® DC 2, and POLYCAT® SA 5 are highly efficient and can be used at low levels as co-catalysts in existing formulations to help increase the cure speed of the system without affecting the front-end of the reaction, while maintaining working life.

DABCO® DC 1 vs DABCO® 33 LV

POLYCAT® SA 20 vs DABCO® T 12

Adjusted to similar pot life times

Applications & Uses

- Markets

- Applicable Processes

- Cure Method

- Adhesive & Sealant Type

- Industrial Additives End Use

- Product Applications

- DABCO® T 12 finds greatest use in the manufacture of rigid polyurethane foams. In de- manding applications where amine catalysis alone is inadequate, the extra activity obtained by the synergistic combination of organometallics like DABCO® T 12 with an amine catalyst permits the required rapid catalysis. Examples include high- density structural foam, spray-up wall insulation and rigid boardstock run at high line speeds. Even when used at levels as low as 0.1 phr based on polyol, DABCO® T 12 is especially effective in promoting rapid gel and tack-free times. Tetravalent diorganotins like DABCO® T 12 are known throughout the industry as promoters of the reaction of isocyanates with polyols to form polyurethanes, and of the secondary crosslinking reactions to form allophonate and biuret linkages.

- Because of this selectivity for polymerization, DABCO® T 12 is often a benchmark in the catalysis of polyurethane systems including two- component adhesives and moisture-cure coatings, where the oxidative stability of tetravalent tins permits masterbatching of components.

- Use-life and retention of catalytic activity of such a masterbatch are dependent upon the presence of amines, moisture and other additives as well as on the storage temperatures. Organotin carboxylates will hydrolyze like any ester, so applications de- manding specific pot lives should be laboratory screened first.

Properties

- Physical Form

- Appearance

- Light yellow liquid

- Insoluble in

- Water

- Typical Properties

- Product Properties

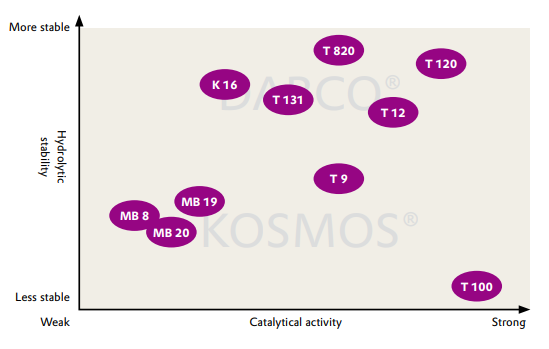

DABCO® series organotin and bismuth metal catalysts can optimize material properties and curing behavior

| Value | Units | Test Method / Conditions | |

| Viscosity (at 25°C) | 125 | mPa.s | — |

| Density (at 21°C) | 1.03 | g/cm³ | — |

| Calculated OH Number | 0 | mg KOH/g | — |

| Flash Point | min. 204 | °C | PMCC |

Technical Details & Test Data

- Specialty Catalysts – High Sustainability

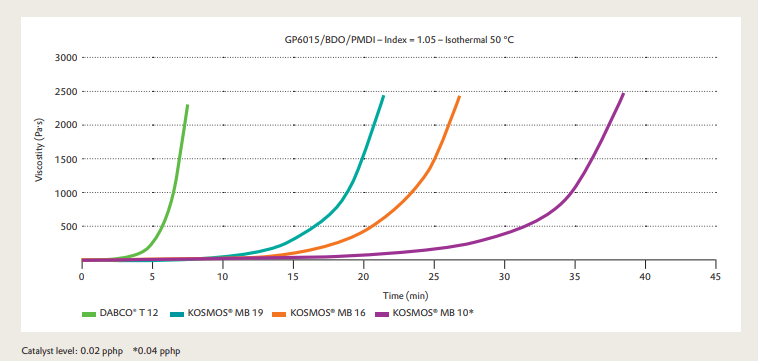

Organotin catalysts, like Dibutyl Tin Dilaurate (DBTL) and Dioctyl Tin Dilaurate (DOTL), are constantly under regulatory threat and have special labeling requirements when being used around the world. With these challenges, formulators need to be aware and ready with suitable alternatives. At Evonik, sustainability is the central element behind our purpose "Leading Beyond Chemistry" and we are committed to providing innovative solutions that help to make our lives more sustainable, healthier, and more comfortable. To help drive this initiative, we have recently launched a series of bismuth catalysts under the KOSMOS® MB tradename. The KOSMOS® MB series are Bismuth-based catalysts are versatile alternatives to traditional Organotin catalysts. KOSMOS® MB 16 and MB 19 are 16 and 20 wt% bismuth dissolved in neodecanoic acid. And KOSMOS® MB 10 is a specialty developed grade of bismuth that has been optimized for moisture stability to ensure a consistent pot life and cure time during extended storage and application. This technology enables formulators and manufacturers to use ecologically safe polyurethane catalysts and create products and systems that are Tin-, Lead and Mercury-free. Furthermore, they exhibit low volatility with little or no odor. KOSMOS MB® series are ideal for all type of Coating, Adhesives & Sealants and Elastomers polyurethane applications

Viscosity profiles of KOSMOS® MB series and of DABCO® T 12 (DBTL)

Storage & Handling

- Shelf Life

- 12 months

- Storage Conditions

- Shelf life: minimum 12 months.

- Storage conditions: dry and cool place in factory-packed containers.

- Optimum storage temperature: 10 to 30°C.