Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Rheological Calculation Properties

- Test Specimen Production

- Rheological Properties

- Burn Testing Properties

| Value | Units | Test Method / Conditions | |

| Tensile Modulus (dry) | 319000 | psi | ISO 527 |

| Tensile Modulus (cond.) | 247000 | psi | ISO 527 |

| Tensile Strength (dry) | 8410 | psi | ISO 527 |

| Yield Stress (dry) | 8410 | psi | ISO 527 |

| Yield Stress (cond.) | 7690 | psi | ISO 527 |

| Yield Strain (dry) | 4 | % | ISO 527 |

| Yield Strain (cond.) | 16 | % | ISO 527 |

| Stress at 50% Strain (dry) | 5950 | psi | ISO 527 |

| Stress at Break (dry) | 6090 | psi | ISO 527 |

| Nominal Strain at Break (ɛtb, dry) | 115 | % | ISO 527 |

| Nominal Strain at Break (ɛtb, cond.) | min. 50 | % | ISO 527 |

| Typical for the Mat. Nom. Strain at Break (ɛtb) | 92 | % | ISO 527 |

| Charpy Notched Impact Strength (+23°C, dry) | 2.38 | ftlb/in² | ISO 179/1eA |

| Charpy Notched Impact Strength (+23°C, cond.) | 2.85 | ftlb/in² | ISO 179/1eA |

| Charpy Notched Impact Strength (-30°C, dry) | 2.85 | ftlb/in² | ISO 179/1eA |

| Charpy Notched Impact Strength (-30°C, cond.) | 2.85 | ftlb/in² | ISO 179/1eA |

| Flexural Modulus (23°C, dry) | 287000 | psi | ISO 178 |

| Flexural Modulus (23°C, cond.) | 189000 | psi | ISO 178 |

| Flexural Stress at Conv. Deflection (23°C, dry) | 9570 | psi | ISO 178 |

| Flexural Stress at Conv. Deflection (23°C, cond.) | 5800 | psi | ISO 178 |

| Flexural Strength (23°C, dry) | 11300 | psi | ISO 178 |

| Flexural Strength (23°C, cond.) | 7980 | psi | ISO 178 |

| Flexural Strain at Flexural Strength (23°C, dry) | 7 | % | ISO 178 |

| Flexural Strain at Flexural Strength (23°C, cond.) | 9 | % | ISO 178 |

| Puncture - Maximum Force (+23°C, dry) | 985 | Ibf | ISO 6603-2 |

| Puncture - Maximum Force (-30°C, dry) | 1280 | Ibf | ISO 6603-2 |

| Puncture Energy (+23°C, dry) | 469 | in-lb | ISO 6603-2 |

| Puncture Energy (-30°C, dry) | 531 | in-Ib | ISO 6603-2 |

| Value | Units | Test Method / Conditions | |

| Density (dry) | 1.06 | g/cm³ | ISO 1183 |

| Water Absorption (dry) | 2.7 | % | Sim. to 1SO 62 |

| Humidity Absorption (dry) | 1 | % | Sim. to ISO 62 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (dry) | 419 | °F | ISO 11357-1/-3 |

| Glass Transition Temperature (dry) | 113 | °F | ISO 11357-1/-2 |

| Temperature of Deflection Under Load A (1.80 Mpa, dry) | 149 | °F | ISO 75-1/-2 |

| Temperature of Deflection Under Load B (0.45 Mpa, dry) | 302 | °F | ISO 75-1/-2 |

| Vicat Softening Temperature A (10 N, 50 K/h, dry) | 419 | °F | ISO 306 |

| Vicat Softening Temperature B (50 N, 50 K/h, dry) | 356 | °F | ISO 306 |

| Coefficient of Linear Thermal Expansion (23°C to 55 °C, Parallel, dry) | 7.22e-05 | in/in/°F | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (23°C to 55 °C, Normal, dry) | 6.67e-05 | in/in/°F | ISO 11359-1/-2 |

| Melting Temperature | 419 | °F | ASTM D 3418 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity (pV, dry) | min. 1E13 | Ohm*m | IEC 62631-3-1 |

| Volume Resistivity (pV, cond.) | 1000000000000 | Ohm*m | IEC 62631-3-1 |

| Relative Permittivity (100Hz, dry) | 3.8 | — | IEC 62631-2-1 |

| Relative Permittivity (100Hz, cond.) | 4.5 | — | IEC 62631-2-1 |

| Relative Permittivity (1MHz, dry) | 3.2 | — | IEC 62631-2-1 |

| Relative Permittivity (1MHz, cond.) | 441 | — | IEC 62631-2-1 |

| Dissipation Factor (100Hz, dry) | 240 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (100Hz, cond.) | 590 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (1Mhz, dry) | 290 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (1Mhz, cond.) | 510 | E-4 | IEC 62631-2-1 |

| Electric Strength (AC, S20/S20, t. 1 mm, dry) | 711 | kV/in | IEC 60243-1 |

| Electric Strength (AC, S20/S20, t. 1 mm, cond.) | 686 | kV/in | IEC 60243-1 |

| Electric Strength (AC, S20/P50, dry) | 711 | V/ mil | Sim. to IEC 60243-1 |

| Value | Units | Test Method / Conditions | |

| Minimum Mold Temperature | 86 | °F | — |

| Maximum Mold Temperature | 212 | °F | — |

| Minimum Melt Temperature | 446 | °F | — |

| Maximum Melt Temperature | 518 | °F | — |

| Value | Units | Test Method / Conditions | |

| Injection Molding - Melt Temperature | 482 | °F | ISO 294 |

| Injection Molding - Mold Temperature | 176 | °F | ISO 294 |

| Injection Molding - Injection Velocity | 7.87 | in/s | ISO 294 |

| Injection Molding - Pressure at Hold | 10200 | psi | ISO 294 |

| Value | Units | Test Method / Conditions | |

| Melt Volume Flow Rate (dry, at 464°F, 1lb) | 75 | cm³/10min | ISO 1133 |

| Molding Shrinkage (Parallel, dry) | 1.3 | % | ISO 294-4, 2577 |

| Molding Shrinkage (Normal, dry) | 1.4 | % | ISO 294-4, 2577 |

| Mold Temperature (dry) | 176 | °F | — |

| Melt Temperature (dry) | 482 | °F | — |

| Value | Units | Test Method / Conditions | |

| Burning Behavior (at 1.5 mm Nominal Thickness) (dry) | HB | class | IEC 60695-11-10 |

| Burning Behavior (at Thickness 0.1260 in.) (dry) | HB | class | IEC 60695-11-10 |

Technical Details & Test Data

- Viscosity-Shear Rate HKR

- Shearstress-Shear Rate HKR

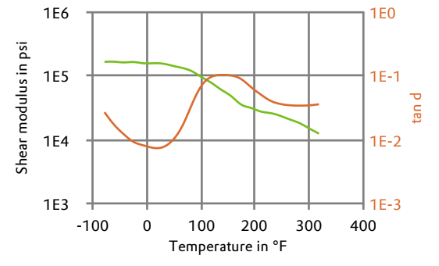

- Dynamic Shear Modulus-Temperature (Dry)

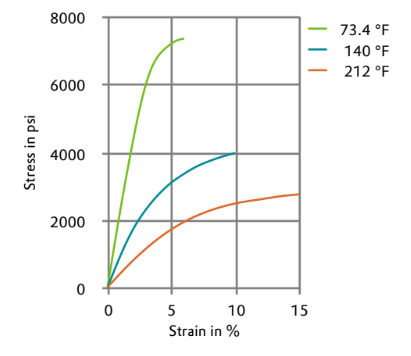

- Stress-Strain (Dry)

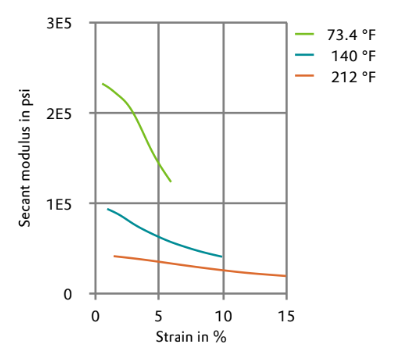

- Secant Modulus-Strain (Dry)

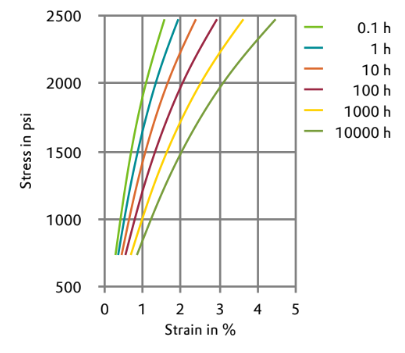

- Stress-Strain (Isochronous) 73°F (Cond.)

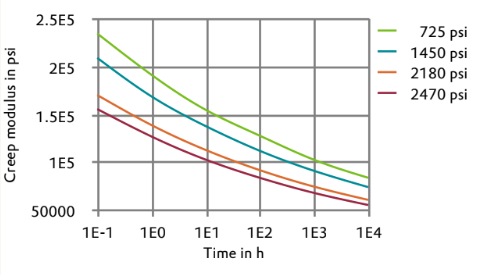

- Creep Modulus-Time 73°F (Cond.)

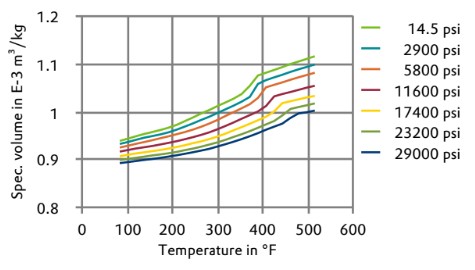

- Specific Volume-Temperature (pvT)

Packaging & Availability

- Packaging Type

- Packaging Information

VESTAMID® D16 is supplied as cylindrical granules in moisture-proof polyethylene containers ready for processing.