Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Rheological Calculation Properties

- Other Properties

- Test Specimen Production

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Tensile Modulus (dry) | 525 | MPa | ISO 527-1/-2 |

| Tensile Modulus (cond.) | 450 | MPa | ISO 527-1/-2 |

| Yield Stress (dry) | 30 | MPa | ISO 527-1/-2 |

| Yield Stress (cond.) | 28 | MPa | ISO 527-1/-2 |

| Yield Strain (dry) | 27 | % | ISO 527-1/-2 |

| Yield Strain (cond.) | 26 | % | ISO 527-1/-2 |

| Nominal Strain at Break (dry) | min. 50 | % | ISO 527-1/-2 |

| Nominal Strain at Break (cond.) | min. 50 | % | ISO 527-1/-2 |

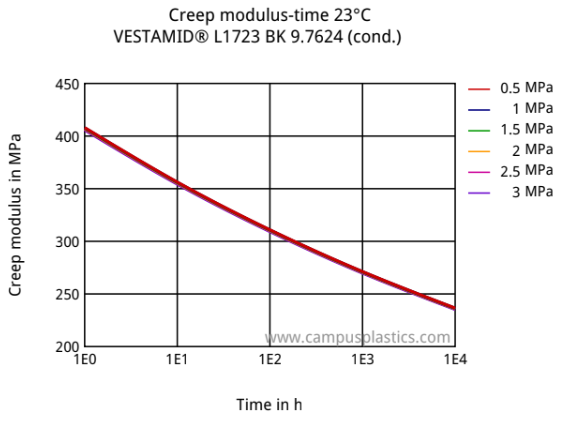

| Tensile Creep Modulus (1h, cond.) | 380 | MPa | 1S0 899-1 |

| Tensile Creep Modulus (1000h, cond.) | 290 | MPa | 1S0 899-1 |

| Charpy Notched Impact Strength (+23°C, dry) | 15C | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (+23°C, cond.) | 41C | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (-30°C, dry) | 5C | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (-30°C, cond.) | 5C | kJ/m² | ISO 179/1eA |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min, dry) | 173 | °C | ISO 11357-1/-3 |

| Temperature of Deflection Under Load (1.80 Mpa, dry) | 45 | °C | 150 75-1/-2 |

| Temperature of Deflection Under Load (0.45 Mpa, dry) | 95 | °C | 150 75-1/-2 |

| Vicat Softening Temperature (50°C/h 50N, dry) | 130 | °C | ISO 306 |

| Coefficient of Linear Thermal Expansion (Parallel, dry) | 180 | E-6/K | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (Normal, dry) | 180 | E-6/K | 1SO 11359-1/-2 |

| Burning Behavior (at 1.5 mm Nominal Thickness) (dry) | HB | class | IEC 60695-11-10 |

| Burning Behavior (at Thickness 0.8 mm) (dry) | HB | class | IEC 60695-11-10 |

| Value | Units | Test Method / Conditions | |

| Relative Permittivity (100Hz, dry) | 10 | — | IEC 62631-2-1 |

| Relative Permittivity (100Hz, cond.) | 14 | — | IEC 62631-2-1 |

| Relative Permittivity (1MHz, dry) | 3.7 | — | IEC 62631-2-1 |

| Relative Permittivity (1MHz, cond.) | 4.3 | — | IEC 62631-2-1 |

| Dissipation Factor (100Hz, dry) | 1600 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (100Hz, cond.) | 1400 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (1Mhz, dry) | 1200 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (1Mhz, cond.) | 1700 | E-4 | IEC 62631-2-1 |

| Volume Resistivity (dry) | 1E10 | Ohm*m | IEC 62631-3-1 |

| Volume Resistivity (cond.) | 4E9 | Ohm*m | IEC 62631-3-1 |

| Surface Resistivity (cond.) | 2E13 | Ohm | IEC 62631-3-2 |

| Electric Strength (dry) | 33 | kv/mm | IEC 60243-1 |

| Electric Strength (cond.) | 31 | kv/mm | IEC 60243-1 |

| Comparative Tracking Index (dry) | 600 | — | IEC 60112 |

| Comparative Tracking Index (cond.) | 600 | — | IEC 60112 |

| Value | Units | Test Method / Conditions | |

| Density of Melt | 860 | kg/m³ | — |

| Specific Heat Capacity Melt | 3000 | J/(kg-K) | — |

| Ejection Temperature | 170 | °C | — |

| Value | Units | Test Method / Conditions | |

| Humidity Absorption (dry) | 5 | % | Sim. to ISO 62 |

| Density (dry) | 1030 | kg/m³ | ISO 1183 |

| Density (cond.) | 1040 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Injection Molding - Melt Temperature | 200 | °C | 1S0O 294 |

| Injection Molding - Mold Temperature | 60 | °C | 1S0O 294 |

| Injection Molding - Injection Velocity | 200 | mm/s | 1S0O 294 |

| Injection Molding - Pressure at Hold | 70 | MPa | 1S0O 294 |

| Value | Units | Test Method / Conditions | |

| Melt Volume Flow Rate (dry, at 230°C, 5kg) | 160 | cm³/10min | 1S0 1133 |

| Molding Shrinkage (Parallel, dry) | 16 | % | ISO 294-4, 2577 |

| Molding Shrinkage (Normal, dry) | 15 | % | 1S0 294-4, 2577 |

Technical Details & Test Data

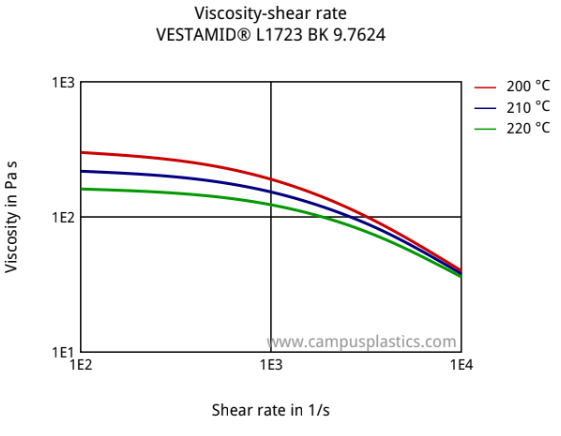

- Viscosity - Shear Rate

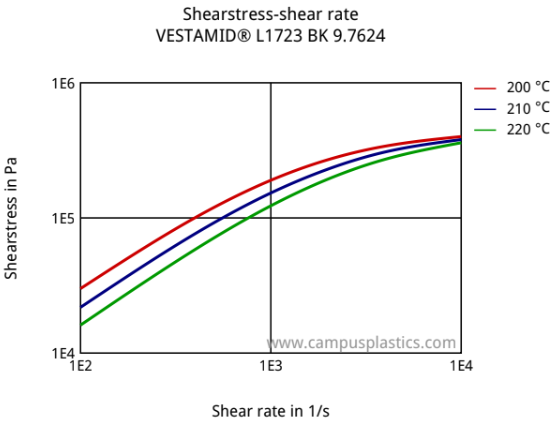

- Shearstress - Shear Rate

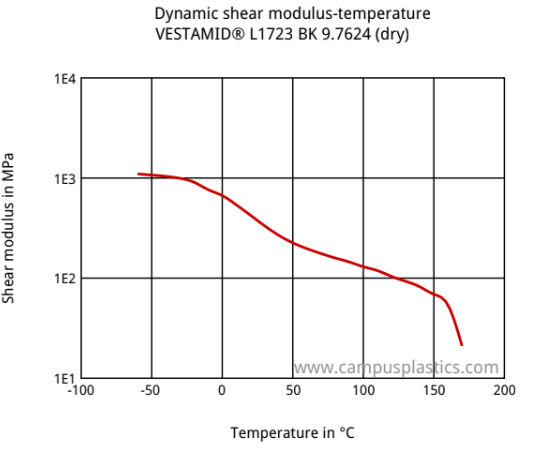

- Dynamic Shear Modulus - Temperature

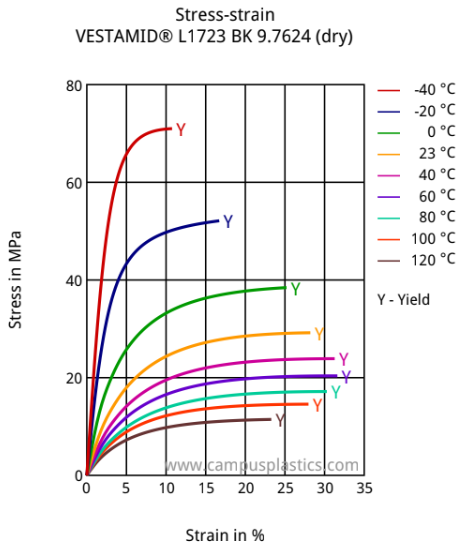

- Stress - Strain

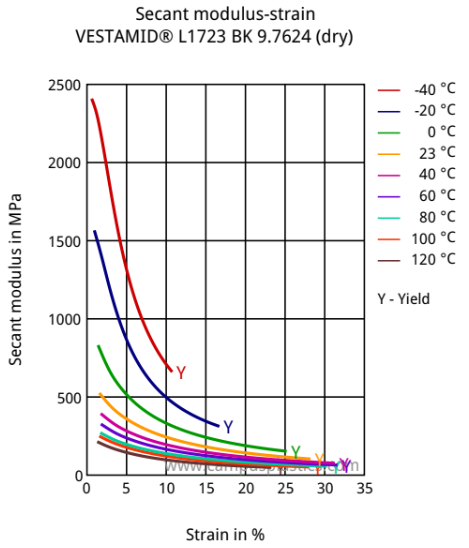

- Secant Modulus - Strain

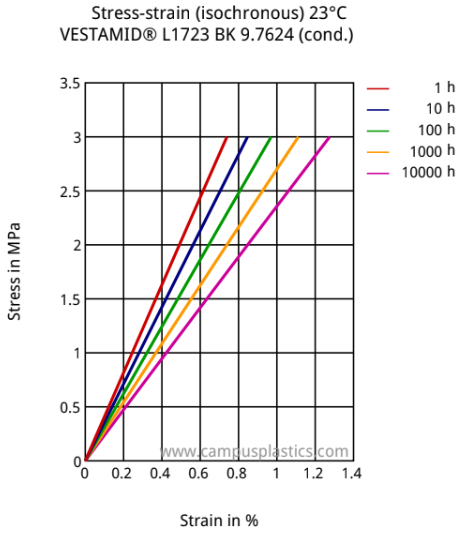

- Stress - Strain (isochronous) 23°C

- Creep Modulus - Time 23°C

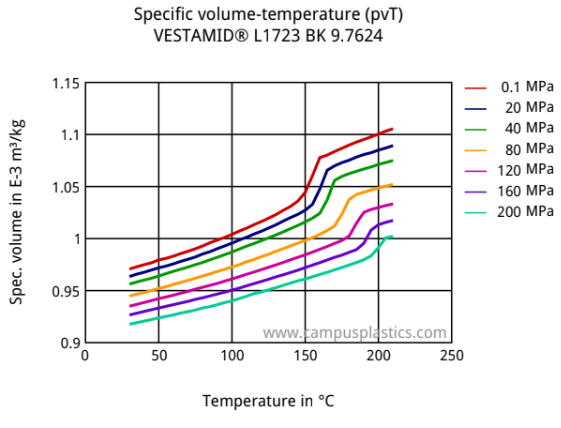

- Specific Volume - Temperature (pvT)

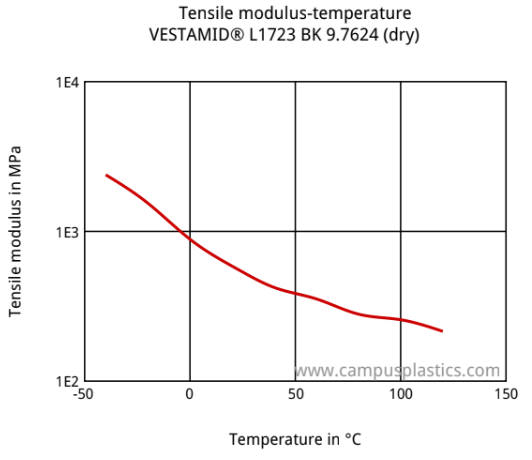

- Tensile Modulus - Temperature

Packaging & Availability

- Regional Availability

- Packaging Information

VESTAMID® L1723 BK 9.7624 is supplied as cylindrical granules, ready for processing in moisture-proof packaging.

Storage & Handling

- Shelf Life

- 2 years

- Storage Conditions

Inside the original and undamaged packaging, the product has a shelf life of at least 2 years when stored in dry rooms at temperatures not exceeding 30°C.