Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Advantages

- Excellent anti-settling property

- Imparts high thixotropic property without excess viscosity increasing

- Easy incorporation

Applications & Uses

- Applications

- Coating Type

- Use Level

- 1 - 6 wt. % (Total Formulation)

- Applications

DISPARLON AQ-870 can be used in a wide range of waterborne coating systems.

Properties

- Physical Form

- Appearance

- Yellow liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Active Matter | 15 | wt.% | — |

| Amine | N, N-dimethylethanolamine | — | — |

| Acid Value | 9.1 | — | — |

| Solvent | Water /2ethylhexylalcohol | — | — |

Technical Details & Test Data

- Instruction

Product’s Viscosity

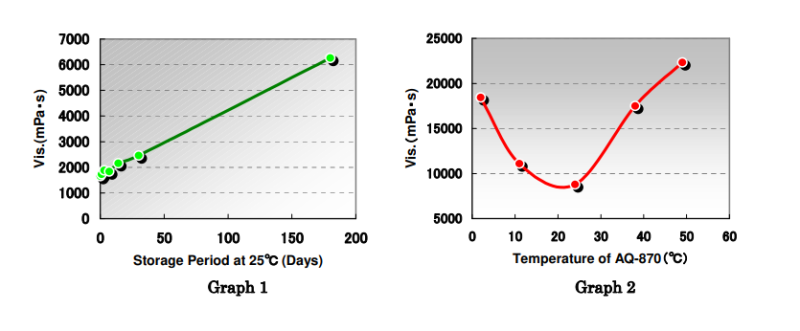

The viscosity of this product gradually increases during storage (Graph 1), and is temperature depending (Graph 2). Storage at around 25°C is recommended to get lower viscosity.

Flow property

At low temperature (below 10°C), this product loses the fluidity and becomes paste form. In this case, heat at 50°C or more for about 24 hours to fluidize it again.

Storage (days) 0 1 3 7 14 30 Viscosity at 0°C (mPa.s) 1656 min. 10000 min. 10000 min. 10000 Not flowable Not flowable Viscosity at 10°C (mPa.s) 1656 4190 4310 4750 5720 7620 Viscosity at 20°C (mPa.s) 1656 2220 2300 2450 2670 3070 *Brookfield Viscometer

Storage & Handling

- Storage Conditions

- Keep from freezing. Freezing causes degradation of quality and performance.

- At low temperature (below 10°C), this product loses the fluidity and becomes paste form. In this case, heat at 50°C or more and fluidize again before use.