Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Highlights

- Chemical and grease resistance

- Fast set

- Air filters

- High-temperature resistance

- Good low-temperature flexibility

Applications & Uses

- Markets

- Applications

- Adhesive & Sealant Type

- Applications

- Packaging

- Air filters

- Textiles

Properties

- Sales Specifications

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Softening Point (Ring & Ball) | 150 - 165 | °C | ASTM E28 (AQCM 003) |

| Viscosity LVT Brookfield, Spindle #31, cps/mPA.s 190°C | 1800 - 3200 | — | ASTM D3236 (AQCM 146) |

| Color , 40% in n-Butanol | max. 7 | Gardner | AQCM 002 |

| Value | Units | Test Method / Conditions | |

| Acid Number | 9.5 | mg KOH/g | AQCM 001 |

| Amine Number | 0.6 | mg KOH/g | AQCM 139 |

| Color , 40% in n-Butanol | 5+ | Gardner | AQCM 002 |

| Moisture Quintel Moisture Analyzer | 0.22 | % | AQCM 056 |

| Tensile Strength | 600 (4.1) | Mpa | ASTM D1708 |

| Elongation at Break | 150.0 | % | ASTM D1708 |

| Tensile Modulus | 16000 (110) | Mpa | ASTM D638 |

| Mandrel Bend Flexibility (1” diameter), pass | -25.0 | °C | ASTM D3111 |

| Open Time seconds, 10 mil film | max. 5 | — | ASTM D4497 |

| Shear Adhesion Failure Temp (SAFT), 1 kg. wt. C | 132.0 | — | ASTM D4498 |

| Hardness | 74 | Shore A | ASTM D2240-97 |

| Pounds per gallon 25°C | 8.1 (0.97) | g/cc | ASTM D792 |

| Flash Point (COC) | 271 (520) | °C (°F) | ASTM D92-16 |

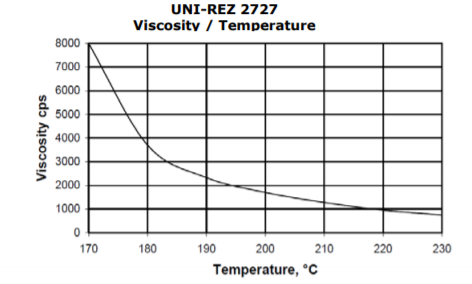

Technical Details & Test Data

- Viscosity/Temperature Curve

Packaging & Availability

- Packaging

- UNI-REZ 2727 hot melt polyamide adhesive is in pellet form, packaged in poly-foil lined multi-wall bags, 40 or 50 lb . net

Storage & Handling

- Storage

This product will slowly absorb moisture from the air, which may cause foaming when the resin is melted and could result in inadequate bonds. Partially used containers should be closed tightly, or the remaining resin transferred into an airtight container and kept in a cool, dry area.