Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Features

- High impact strength in all temperature zone

- Excellent flame retardance

- Hydrolysis resistance.

- Product Benefits

PVC

- Processability

- Mechanical Properties

- Dispersibility of Fillers

- Productivity

Engineering Plastics

- Mechanical Properties

- Flame retardancy

- Processability

Polyolefins Elastomers

- Processability

- Flame retardancy

- Dispersibility of Fillers

- Productivity improvement

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Applications

- Automotive & Transportation

- Electric & Electronic

- Aerospace & Aviation

- Consumer goods

Properties

- Typical Properties

- Compatible Polymers & Resins

PC,PC/ABS, PC/AS. PC/PEs, PC/Filler

| Value | Units | Test Method / Conditions | |

| Particle Size | approx. 0.1 - 1 | µm | — |

Technical Details & Test Data

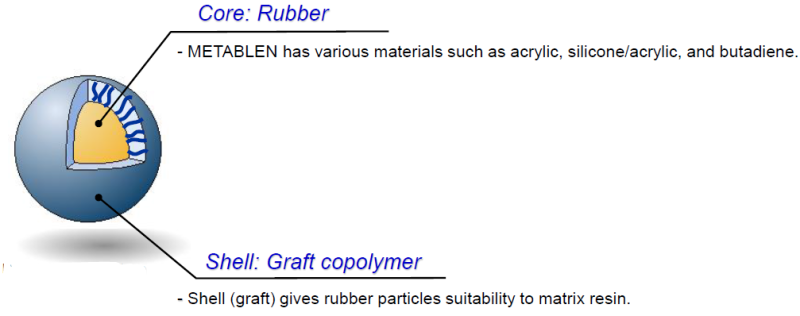

- METABLEN's Impact Modifier Technology

Particle size: 0.1~1μm

Rubber type Rubber elasticity(at R.T.) Rubber elasticity(at low temp.) Weatherability Acrylic ++ + ++ Silicone/Acrylic ++ ++ ++ Butadiene ++ ++ - METABLENT SX-005 is silicone-acrylic rubber type impact modifier

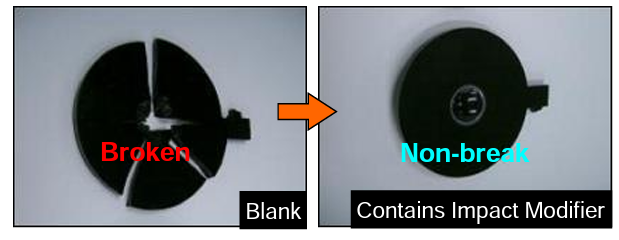

- Improved Plastic Toughness

- METABLEN SX-005: Impact Modifier for PC

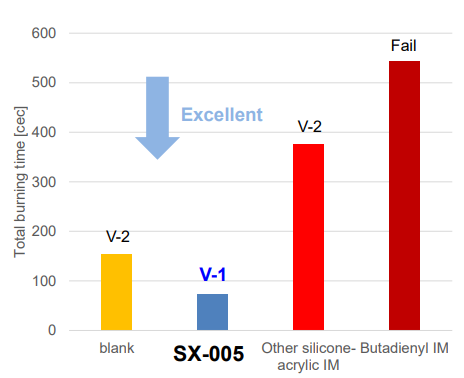

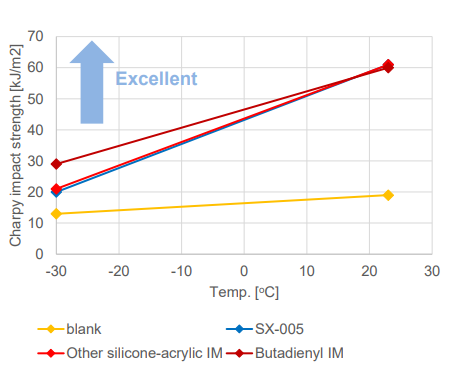

METABLEN SX-005 is impact modifier containing high level of siloxane polymer. This grade has a better balance between flame retardancy and low-temperature impact strength.

Figure: UL-94 test results of PC.

Formulation: PC/IM/A-3800/thermal stabilizer = 100/5/1/0.6 (wt %)

Figure: Charpy impact strength of PC.

Formulation: PC/IM/A-3800/thermal stabilizer = 100/5/1/0.6 (wt %)

Impact test: Thickness: 1/4 inch, Temperature: 23 or -30ºC*METABLEN™ A-3800 is anti-dripping agent composed of acrylic-modified PTFE for flame retardant formulation.