Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Food Ingredients Functions

- Technologies

Features & Benefits

- Labeling Claims

- Food Ingredients Features

- Product Features

- Crumb softening or shelf-life extension by reducing the rate of starch retrogradation.

- Dough strengthening for better gas retention and optimum bread volume.

- Compensation for variations in raw materials (e.g., flour quality).

- Enhance hydration of the flour and other ingredients.

- Improved dough machinability by gluten complexing.

- Greater tolerance to production stress of dough by providing a drier, less sticky dough. This reduces tearing and facilitates easier processing.

- Ease of formulating low-fat products; reduction in shortening or oil with no loss of volume, softness, or slicing ease.

- Increased gas retention, resulting in lower yeast requirements, improved oven spring, shorter proof times, and increased volume.

- Better texture of finished bread - i.e., finer grain.

- Stronger side walls, improved symmetry, and reduction of deformed bread.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Formulation Considerations

- Dough conditioners - No additional emulsifiers are needed. MASEMUL® EB 1005 is specially developed to be a full solution.

- Yeast - Addition 1.0 - 1.5% yeast when the blends used are other types of flour like whole meal, multigrain and rye.

- Dough temperature - Dough temperature at the end of mixing should be at 82 - 86°F (28 - 30°C). This helps to boost yeast activity and slightly decrease elasticity and resistance to deformation for good machining.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Outcome and Results

By using MASEMUL® EB 1005, volume, softness, cell structure, shelf life and eating parameters of bread will be enhanced.

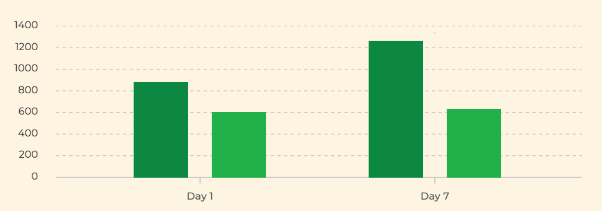

Wholemeal bread with MASEMUL® EB 1005

Days Blank Day 1 874.15 599.7 Day 7 1216.3 649.05 Comparison of hardness between Blank and MASEMUL® EB 1005 for Day 1 and Day 7

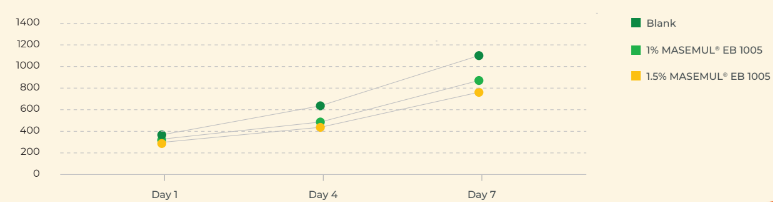

White bread with MASEMUL® EB 1005

Days Blank 1% MASEMUL® EB 1005 Day 1 386.5 346.6 316.6 Day 4 655.6 505.4 456.6 Day 7 1121 890.3 781.3 Change in hardness of breads with different dosage MASEMUL® EB 1005 over storage periods of 7 days