Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Thermocomp™ Compounds For Dielectric Solutions

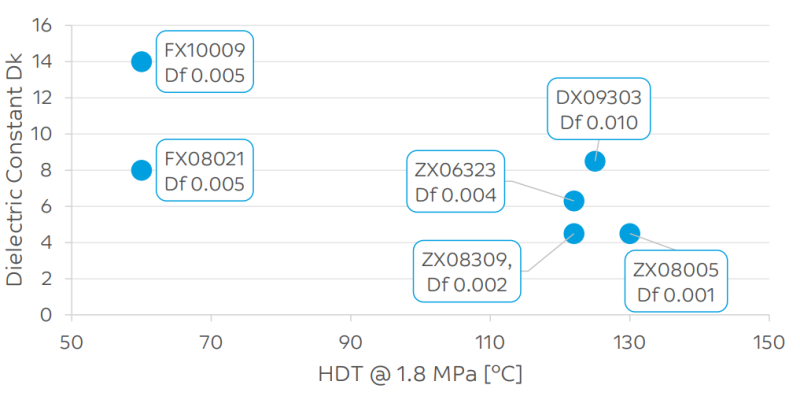

LNP™ THERMOCOMP compounds portfolio contains thermoplastic injection molding materials that offer low Dissipation Factor (Df ) for improved signal gain and longer reading distance paired with tailor made Dielectric Constants (Dk ) to fine tune or detour a signal direction supporting innovative antenna designs. Beyond that, THERMOCOMP compounds allow further antenna miniaturization and the design of phase shifters with higher productivity through combined high Dk and low Df material properties.

Typical Industry Requirements

- Materials for individual antenna design to fine tune or detour signal direction.

- Improved signal gain and longer reading distance through less signal attenuation.

- Miniaturized antenna solutions with sufficient signal strength for 5G technology.

- Improved mechanical performance versus Epoxy or Ceramics in more complex designs for less maintenance through longer lifetime.

Typical Material Characteristics

- Tailored Dielectric Constant Dk by customized compound formulations.

- Very low Dissipation Factor Df for lower signal absorption, less signal scattering.

- Combined high Dk and low Df with very high signal transmission density.

- Sufficient flowability for thin wall design, improved ductility, dimensional and dielectric stability versus current solution.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Impact Properties

- Injection Molding

- Flame Characteristics

- Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Break, Type I, 5 mm/min) ¹¹ | 54 | MPa | ASTM D638 |

| Tensile Strain (Break, Type I, 5 mm/min) ¹¹ | 4.2 | % | ASTM D638 |

| Tensile Modulus (at 5 mm/min) ¹¹ | 4140 | MPa | ASTM D638 |

| Flexural Stress (Yield, 1.3 mm/min, 50 mm span) ¹¹ | 102 | MPa | ASTM D790 |

| Flexural Stress (Break, 1.3 mm/min, 50 mm span) ¹¹ | 102 | MPa | ASTM D790 |

| Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ | 3940 | MPa | ASTM D790 |

| Tensile Stress (Break, 5 mm/min) ¹¹ | 54 | MPa | ISO 527 |

| Tensile Strain (Break, 5 mm/min) ¹¹ | 4.7 | % | ISO 527 |

| Tensile Modulus (at 1 mm/min) ¹¹ | 4080 | MPa | ISO 527 |

| Flexural Modulus (at 2 mm/min) ¹¹ | 4390 | MPa | ISO 178 |

| Value | Units | Test Method / Conditions | |

| Density ¹¹ | 1.95 | g/cm³ | ASTM D792 |

| Density ¹¹ | 1.95 | g/cm³ | ISO 1183 |

| Moisture Absorption (at 23°C, 50% RH, 24hrs) ¹¹ | 0.1 | % | ASTM D570 |

| Mold Shrinkage (flow, 24 hrs) ᵍ ¹¹ | 0.64 | % | ASTM D955 |

| Mold Shrinkage (xflow, 24 hrs) ᵍ ¹¹ | 0.56 | % | ASTM D955 |

| Melt Volume Rate (at 300°C, 5.0 kg) ¹¹ | 8 | cm³/10 min | ISO 1133 |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ | 122 | °C | ASTM D648 |

| Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 122 | °C | ISO 75/Af |

| Value | Units | Test Method / Conditions | |

| Dissipation Factor (at 900 MHz) ¹¹ | 0.003 | — | ASTM D150 |

| Relative Permittivity (900MHz) ¹¹ | 6.4 | — | ASTM D2520 - Mth B |

| Value | Units | Test Method / Conditions | |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 294 | J/m | ASTM D4812 |

| Izod Impact (Notched, at 23°C) ¹¹ | 46 | J/m | ASTM D256 |

| Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ | 20 | kJ/m² | ISO 180/1U |

| Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ | 5 | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Drying Temperature ⁷ | 105 | °C | — |

| Drying Time ⁷ | 3 - 5 | Hrs | — |

| Melt Temperature ⁷ | 295 - 305 | °C | — |

| Nozzle Temperature ⁷ | 290 - 295 | °C | — |

| Front - Zone 3 Temperature ⁷ | 300 - 305 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 290 - 295 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 280 - 285 | °C | — |

| Mold Temperature ⁷ | 9.00E+01 | °C | — |

| Back Pressure ⁷ | 9 | MPa | — |

| Screw Speed ⁷ | 100 | rpm | — |

| Value | Units | Test Method / Conditions | |

| UL Recognized (94HB Flame Class Rating) ᵖ | min. 1.5 | mm | UL 94 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Typical Properties of Thermocomp Compounds for Dielectric Solutions

Packaging & Availability

- Country Availability

- Regional Availability