Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Benefits

- Long Term Heat Resistance : Excellent stability of physical and mechanical properties at elevated temperatures thanks to high glass transition temperature of up to 280°C. Available with relative thermal indices (RTI) higher than 200°C (preliminary).

- Strength and Stiffness : Outstanding strength, stiffness and creep resistance with predictable performance up to 230°C (preliminary). EXTEM™ XH resin is approximately 50% stronger at 170°C than ULTEM™ resin. Unfilled, transparent grades are equal in strength to other thermoplastics with opacifying fillers.

- Dimensional Stability : Among the most dimensionally stable thermoplastics available, offering predictability over a broader temperature range exceeding 200°C. Filled grades offer exceptionally high-tolerance dimensional capabilities.

- Environmental Stress & Cracking Resistance : Unlike most other amorphous thermoplastics, EXTEM™ resins retain strength and resist stress cracking when exposed to automotive and aircraft fluids, aliphatic hydrocarbons, alcohols, acids as well as chlorinated solvents such as methylene chloride.

- Flammability, Smoke Generation and Toxicity : Inherently flame-retardant without the use of halogenated additives, which can pose an environmental risk. EXTEM™ resin is exceptionally difficult to ignite, with a limiting oxygen index (LOI) of 45% (preliminary). EXTEM™ resin is expected to retain the UL performance and flame, smoke and toxicity strengths of ULTEM™ resin.

- Processability : EXTEM™ resin can be processed in conventional drying and injection molding or extrusion equipment capable of running ULTEM™ resin and other high heat thermoplastics. EXTEM™ resin can be film and profile extruded, thermoformed, extrusion blow molded, extruded into stock shapes, and injection molded. Flowability can be tailored to meet customer applications through product and processing design and flows similar to ULTEM™ resins.

- Potential Advantages of ULTEM™ Resin DT1820EV

- High flowability for thin-wall design

- Excellent colorful metallization using Physical Vapor Deposition (PVD)

- High surface hardness with good anti-scratch performance

- High gloss surface with high modulus

- Inherent flame retardancy

- Good UV and chemical resistance

- Benefits of ULTEM™ DT1820EV Resin with PVD Metallization

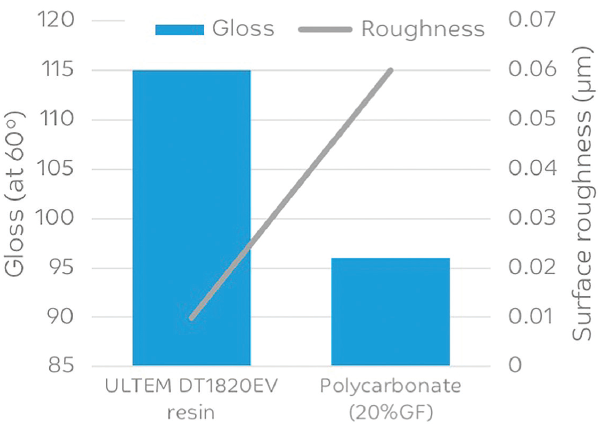

High gloss surface with excellent metallic appearance Glass fiber filled polycarbonate can have a lower quality metallic appearance due to floating fibers

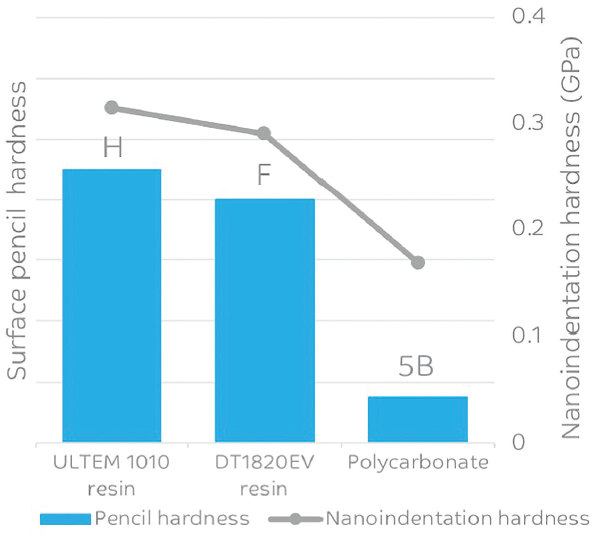

High modulus and hardness with excellent PVD process compatibility Polycarbonate is more easily scratched and the metal layer may crack due to substrate deformation

High heat resistance ULTEM™ resin supports high temperature PVD with better adhesion and shorter cycle time

Small difference in coefficient of thermal expansion (CTE) with PVD layer ULTEM™ resin gives excellent adhesion between PVD layer and the thermoplastic substrate

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Physical Properties

- Mechanical Properties

- Thermal Properties

- Impact Properties

- Injection Molding

- Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

| Value | Units | Test Method / Conditions | |

| Specific Gravity ¹¹ | 1.285 | — | ASTM D792 |

| Density ¹¹ | 1.285 | g/cm³ | ISO 1183 |

| Moisture Absorption (at 23°C, 50% RH, 24hrs) ¹¹ | 0.07 | % | ISO 62-4 |

| Melt Flow Rate (at 350°C, 2.16 kgf) ¹¹ | 24 | g/10 min | ASTM D1238 |

| Melt Flow Rate (at 337°C, 6.7 kgf) ¹¹ | 53 | g/10 min | ASTM D1238 |

| Mold Shrinkage (flow) ᵍ ¹¹ | 0.58 | % | SABIC method |

| Mold Shrinkage (xflow) ᵍ ¹¹ | 0.62 | % | SABIC method |

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Yield, Type I, 50 mm/min) ¹¹ | 107 | MPa | ASTM D638 |

| Tensile Stress (Break, Type I, 50 mm/min) ¹¹ | 80 | MPa | ASTM D638 |

| Tensile Strain (Yield, Type I, 50 mm/min) ¹¹ | 6.8 | % | ASTM D638 |

| Tensile Strain (Break, Type I, 50 mm/min) ¹¹ | 25 | % | ASTM D638 |

| Tensile Modulus (at 50 mm/min) ¹¹ | 3150 | MPa | ASTM D638 |

| Flexural Strength (at 1.3 mm/min, 50 mm span) ¹¹ | 166 | MPa | ASTM D790 |

| Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ | 3190 | MPa | ASTM D790 |

| Tensile Stress (Yield, 50 mm/min) ¹¹ | 108 | MPa | ISO 527 |

| Tensile Stress (Break, 50 mm/min) ¹¹ | 80 | MPa | ISO 527 |

| Tensile Strain (Yield, 50 mm/min) ¹¹ | 6.7 | % | ISO 527 |

| Tensile Strain (Break, 50 mm/min) ¹¹ | 25 | % | ISO 527 |

| Tensile Modulus (at 1 mm/min) ¹¹ | 3090 | MPa | ISO 527 |

| Flexural Strength (at 2 mm/min) ¹¹ | 156 | MPa | ISO 178 |

| Flexural Modulus (at 2 mm/min) ¹¹ | 2950 | MPa | ISO 178 |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (at 0.45 MPa, 3.2 mm, Unannealed) ¹¹ | 182 | °C | ASTM D648 |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ | 168 | °C | ASTM D648 |

| Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 181 | °C | ISO 75/Bf |

| Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 168 | °C | ISO 75/Af |

| Coefficient of Thermal Expansion (at 23°C to 150°C, flow) ¹¹ | 55 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at 23°C to 150°C, flow) ¹¹ | 55 | 1/°C | ISO 11359-2 |

| Coefficient of Thermal Expansion (at 23°C to 150°C, xflow) ¹¹ | 58 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at 23°C to 150°C, xflow) ¹¹ | 58 | 1/°C | ISO 11359-2 |

| Vicat Softening Temperature (Rate B/50) ¹¹ | 184 | °C | ASTM D1525 |

| Vicat Softening Temperature (Rate B/50) ¹¹ | 187 | °C | ISO 306 |

| Vicat Softening Temperature (Rate B/120) ¹¹ | 188 | °C | ISO 306 |

| Vicat Softening Temperature (Rate B/120) ¹¹ | 184 | °C | ASTM D1525 |

| Value | Units | Test Method / Conditions | |

| Izod Impact (Notched, at 23°C) ¹¹ | 40 | J/m | ASTM D256 |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 2097 | J/m | ASTM D4812 |

| Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ | 5 | kJ/m² | ISO 180/1A |

| Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ | 128 | kJ/m² | ISO 180/1U |

| Charpy Impact (at 23°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ | 3.3 | kJ/m² | ISO 179/1eA |

| Charpy Impact (at 23°C, Unnotch Edgew 80*10*4 sp=62mm) ¹¹ | 86 | kJ/m² | ISO 179/1eU |

| Value | Units | Test Method / Conditions | |

| Drying Temperature ⁷ | 135 | °C | — |

| Drying Time ⁷ | 4 - 6 | Hrs | — |

| Drying Time (Cumulative) ⁷ | 24 | Hrs | — |

| Maximum Moisture Content ⁷ | 0.02 | % | — |

| Melt Temperature ⁷ | 320 - 355 | °C | — |

| Nozzle Temperature ⁷ | 325 - 350 | °C | — |

| Front - Zone 3 Temperature ⁷ | 330 - 355 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 320 - 345 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 310 - 330 | °C | — |

| Mold Temperature ⁷ | 110 - 165 | °C | — |

| Back Pressure ⁷ | 0.3 - 0.7 | MPa | — |

| Screw Speed ⁷ | 40 - 70 | rpm | — |

Technical Details & Test Data

- Performance Advantages of Ultem™ Resin DT1820EV

High performance ULTEM DT1820EV resin supports thin-wall, high gloss designs and is an excellent candidate for metal replacement thanks to its surface hardness, good mechanical performance and resistance to UV and chemicals.

- High Flowability For Thinwall Design : Well-suited for thin-wall and complex design with weld line elimination

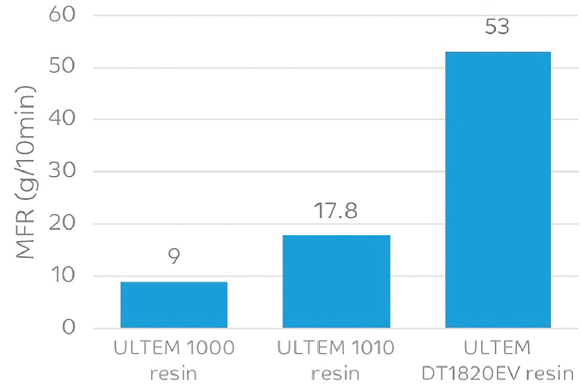

Melt Flow Rate (837°C/6.7kg)

- High Gloss Surface With High Modulus : ULTEM™ DT1820EV resin has high surface gloss with low surface roughness

- High Surface Hardness : ULTEM™ DT1820EV resin shows good anti-scratch and high surface hardness

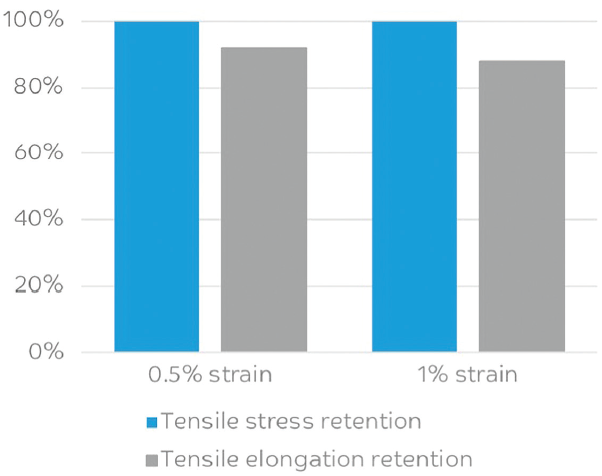

- Good Chemical Resistance : ULTEM™ DT1820EV resin passes the anodization process and has good resistance to sunscreen

- High Flowability For Thinwall Design : Well-suited for thin-wall and complex design with weld line elimination

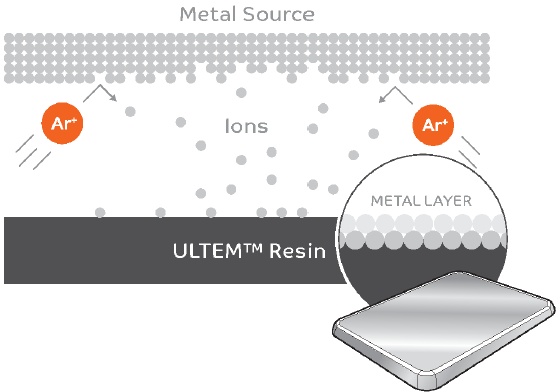

- Colorful Metallization Using PVD

Colorful Metallization Using Physical Vapor Deposition (PVD) : Because of its high modulus and surface hardness, ULTEM™ DT1820EV resin is well-suited for metallization using sputtering PVD. The excellent appearance and good mechanical properties can help to replace metals and may reduce production costs.

ULTEM™ Resin DT1820EV is well suited for PVD sputtering : PVD is a simpler process compared to Non-conductive Vacuum Metallization (NCVM) used with glass fiber filled polycarbonate (PC). PVD provides a better metallic appearance than NCVM and since coloris determined by the PVD layer, this method can eliminate the 3 coating steps used in NCVM. In addition, ULTEM DT1820EV resin’s high heat resistance enables the use of higher temperatures in the PVD process which can improve adhesion and cycle time.

Simplification of The Metallization Process

Top Coating Middle Coating NCVM Base Coating Polycarbonate (20%GF) >> PVD ULTEM™ Resin

Packaging & Availability

- Regional Availability