Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Key Characteristics

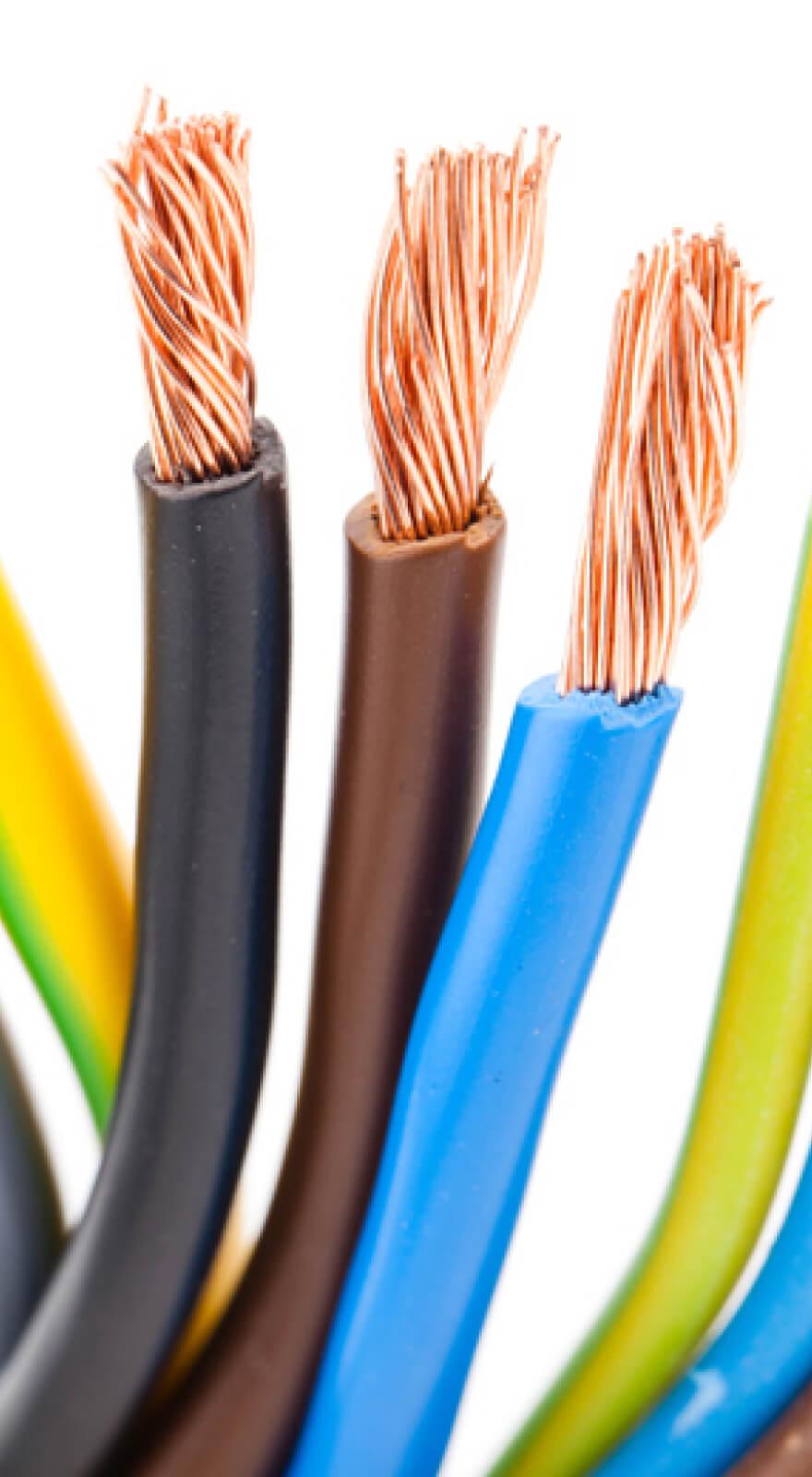

Low smoke, low toxicity, halogen free, flame retardant, silane crosslinkable compound for insulation of LV cables and sheathing of all types of cables rated up to 125°C

Applications & Uses

- Markets

- Applications

- Cure Method

- Plastics & Elastomers Processing Methods

- Applications

Screw Water Temperature: Not mandatory, if present we recommend 40-60°C

Recommended Screen Pack: Spacer ring or breaker plate only

Properties

- Appearance

- Pellets

- Mechanical Properties

- Physical Properties

- Electrical Properties

- Fire & Smoke Properties

- Thermo-Mechanical Properties

| Value | Units | Test Method / Conditions | |

| Elongation at Break | 140 | % | IEC 60811-501 |

| Elongation at Break (After Thermal Aging: 10 days at 150°C) | -15 | % Variation | IEC 60811-401 |

| Elongation at Break (After Thermal Aging: 7 days at 135°C) | -15 | % Variation | IEC 60811-401 |

| Permanent Elongation (After Cooling) | 0 | % | IEC 60811-507 |

| Elongation Under Load (20N/cm² at 200°C) (Cure Assessment by Hot Set Test (Force cured at 80°C in Water) | 50 | % | IEC 60811-507 |

| Tensile Strength | 12 | N/mm² | IEC 60811-501 |

| Tensile Strength (After Thermal Aging: 10 days at 150°C) | 15 | % | IEC 60811-401 |

| Tensile Strength (After Thermal Aging: 7 days at 135°C) | 15 | % | IEC 60811-401 |

| Value | Units | Test Method / Conditions | |

| Density | 1.49 | g/cm³ | BS EN ISO 1183-3 |

| Melt Flow Rate (at 150°C / 2.16kg) | 5 | g/10min | Internal Method |

| Value | Units | Test Method / Conditions | |

| Insulation Resistance Constant (Ki) | 0.285 | Ohm.cm | BS EN 50395 |

| Value | Units | Test Method / Conditions | |

| Conductivity of Gases | 13 | μS/cm | IEC 60754-2 |

| Temperature Index | 260 | °C | BS ISO 4589-3 |

| Temperature Index | 500 | °F | BS ISO 4589-3 |

| Corrosivity of Gases | 4.6 | pH | IEC 60754-2 |

| Halogen Acid Gas Evolution | max. 0.5 | % | IEC 60754-1 |

| Limiting Oxygen Index | 32 | % | BS ISO 4589-2 |

| Smoke Density | max. 3.5 | % | ASTM 2843:2004 |

| Value | Units | Test Method / Conditions | |

| Cold Bend (at -30°C) | Pass | No Cracks | IEC 60811-504 |

| Hot Pressure Deformation (at 100°C) (K=1) | 30 | % | IEC 60811-508 |

Regulatory & Compliance

Technical Details & Test Data

- Processing

Extruder - An extruder with an L/D ratio (length/diameter) between 15 and 24 and a screw with a compression ratio 1.2:1 are recommended.

Extruder Temperature Conditions - It is important that the melt temperature is not allowed to increase above 160oC. As a guide the following temperature profile is recommended:Zone #1 Zone #2 Zone #3 Zone #4 Head Die Celsius 130°C 140°C 145°C 150°C 160°C 160°C Fahrenheit 266°F 284°F 293°F 302°F 329°F 329°F This profile will vary slightly depending on extruder type, head design and output. Initial purging of the extruder should be performed without the addition of catalyst masterbatch to reduce risks of pre-curing.

Packaging & Availability