Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Key Characteristics

Lead free, Thermoplastic CPE Compound

Applications & Uses

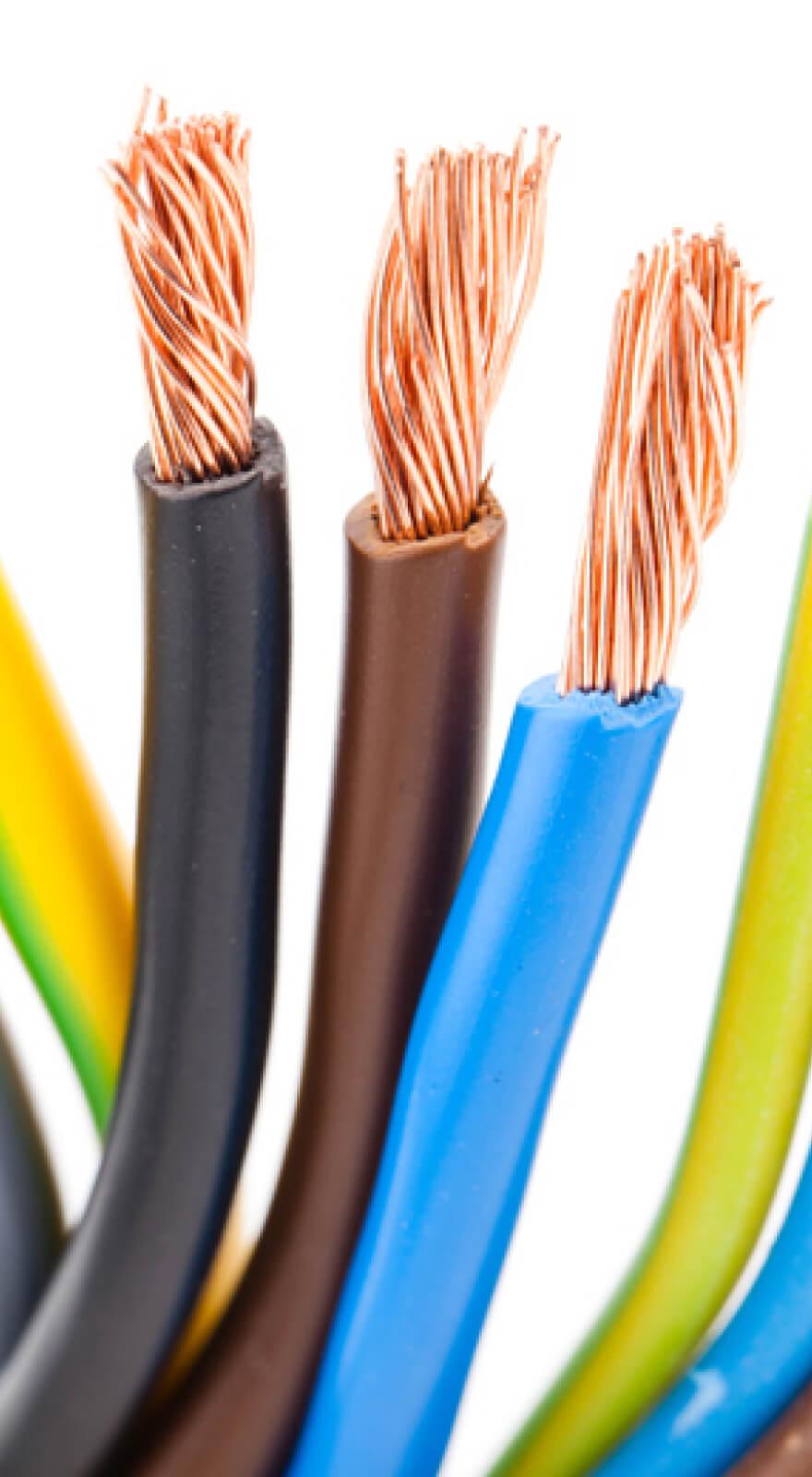

- Markets

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Mechanical Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Deformation Test 2000-gram Load (at 100°C) | 12 | % Deformation | UL 1277 |

| Deformation Test 2000-gram Load (at 121°C) | 24 | % Deformation | UL 1277 |

| Elongation (After 4 Days: 100°C, IRM 902 Oil) | 70 | % Retention | ASTM D638 |

| Elongation (After 60 Days: 75°C, IRM 902 Oil) | 75 | % Retention | ASTM D638 |

| Elongation (After Thermal Aging: 7 Days at 121°C) | 105 | % Retention | ASTM D638 |

| Elongation at Break | 350 | % | ASTM D638 |

| Flexural Modulus (at 1% Secant) | 19900 | psi | ASTM D790 |

| Hardness: Durometer (1-Second) | 93 | Shore A | ASTM D2240 |

| Hardness: Durometer (10-Seconds) | 60 | Shore D | ASTM D2240 |

| Limiting Oxygen Index | 37 | % Oxygen | ASTM D2863 |

| Tensile Strength (After 4 Days: 100°C, IRM 902 Oil) | 65 | % Retention | ASTM D638 |

| Tensile Strength (After 60 Days: 75°C, IRM 902 Oil) | 80 | % Retention | ASTM D638 |

| Tensile Strength (After Thermal Aging: 7 Days at 121°C) | 95 | % Retention | ASTM D638 |

| Tensile Strength at Break | 2200 | psi | ASTM D638 |

| Value | Units | Test Method / Conditions | |

| Low Temperature Brittleness: 3 min in Methanol | -19 | °C | ASTM D746 |

| Melt Flow Rate (at 190°C / 2.16 kg) | 12 | g/10 min | ASTM D1238 |

| Specific Gravity (at 23°C) | 1.38 | g/cm³ | ASTM D792 |

| Tear Strength (at 23°C) | 380 | lb/ft³ | ASTM D470 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Processing

THERMODAN® CP 0110-108 NT can be processed very easily on a wide range of commercially available extrusion equipment. A typical temperature profile would be:

Zone #1 Zone #2 Zone #3 Zone #4 Head Die Melt Temp Celsius 149°-160°C 160°-174°C 174°-185°C 174°-185°C 174°-185°C 188°-199°C 188°-199°C Fahrenheit 300°-320°F 320°-345°F 345°-365°F 345°-365°F 345°-365°F 370°-390°F 370°-390°F It is recommended that THERMODAN® CP 0110-108 NT is pre-dried for 2 – 4 hours at 150⁰F in a heated desiccant system prior to processing. As processes vary widely,

Packaging & Availability

- Packaging Information

THERMODAN® CP 0110-108 NT is packaged in 1400 pounds in poly-lined octagon gaylords (29.5 inches in height). Our technical team is at your disposal for further information and assistance.

Storage & Handling

- Storage and Handling

SACO AEI Polymers recommends that THERMODAN® CP 0110-108 NT be stored in an ambient temperature range (40 to 80⁰F), tightly sealed in its original container and away from moisture and high humidity.