Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Features

PELESTAT HC6800 has the following features:

- Imparts excellent antistatic property to ABS resin when the additive amount is between 10 and 20 wt %. It prevents from dust (surface resistivity value: the range of 1012 Ω) and exerts electrostatic dissipative properties to protect electronic parts and circuits (surface resistivity value: the range of 109 Ω).

- Exhibits a permanent antistatic property immediately after molding and the antistatic properties in the resulting plastic remain mostly unchanged even after being washed with water because it is a high-molecular-weight antistatic agent. In addition, it works even in low humidity due to its low dependency on humidity.

- Minimally affects the mechanical properties and moldability of the resins themselves.

- Does not impair the heat resistance of resins because this product is thermally stable.

- Applicable to electric and electronic parts because it contains almost no halogen ions such as chlorine ions or alkali metal ions.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application Methods

1. General Procedure

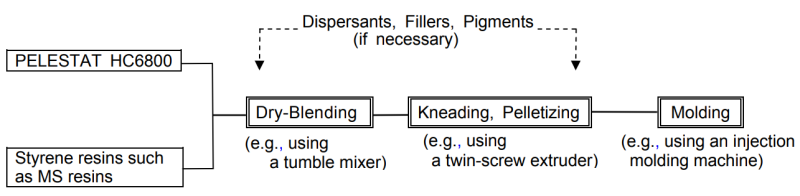

As shown in Figure 1, PELESTAT HC6800 and styrene resins are dry-blended using a blender, and are kneaded and pelletized using a twin-screw extruder and pelletized.

Dispersants, fillers and pigments can be added during the dry-blending or the kneading process if necessary. The pelletized material is then molded into the final product using an appropriate molder (e.g., injection molding machine).

Figure 1. General Procedure for Application of PELESTAT HC6800

2. Amount to be Used The standard amount of PELESTAT HC6800 is between 10 and 20 wt %. Determine the optimal amount by referring to the results of its performance tests.

3. Kneading Conditions Use a high share rate kneader (e.g., twin-screw extruder) when this product is kneaded. The standard kneading temperature is between 210 and 250 °C (410 – 482 °F). Determine the kneading temperature according to the resin applied.4. Control Usage of PELESTAT HC6800

- This product can be immediately used after the sealed package is opened because this product is packaged under moisture-proof conditions.

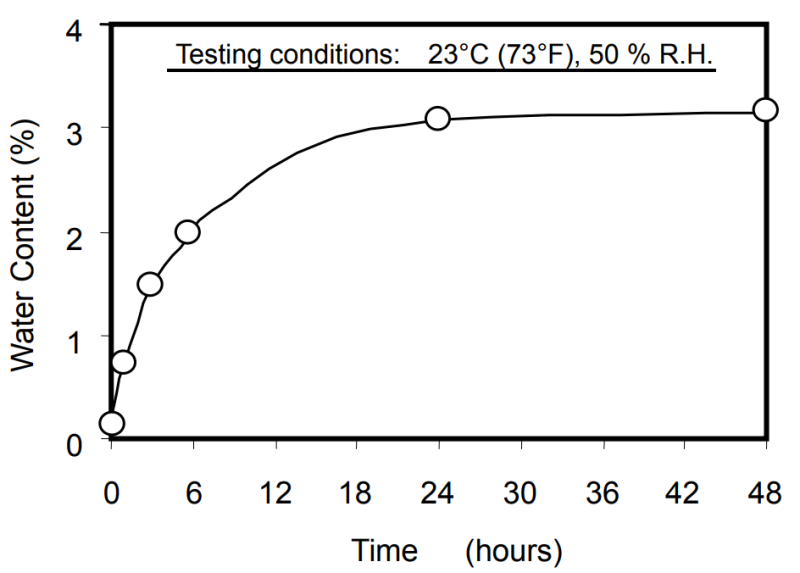

- Drying is necessary when the sealed package is kept unsealed for a long time or when small bubbles form in the molding processes because this product has some hygroscopic properties as described in Figure 2.

- We recommend that you should use a hopper dryer or dehumidifying dryer during the molding process. (because there is a possibility that fisheyes, blisters and silver streaking will occur on molded products of PELESTAT 230 and resins if the water content of the mixture exceeds 500 ppm).

The following are examples of the conditions for drying.

Drying under reduced pressure

Vacuum : Below 1300 Pa (0.2 psi)

Temperature : 70 – 80 °C (158 – 176 °F)

Duration : 2 – 4 hours

Hot-air drying

Temperature : 85 – 95 °C (185 – 203 °F)

Duration : 4 – 6 hours

Hygroscopic Properties of PELESTAT HC6800

- In the case of using resins at molding temperatures at 200 °C (392 °F) or lower, PELESTAT HC6800 may not fuse, possibly resulting in poor effectiveness. Furthermore, in case of using resins at molding temperatures above 300 °C (572 °F), this product may thermally decompose, possibly resulting in poor effectiveness.

- Depending on the kind of resin, this product may have an influence on the resin's physical properties such as mechanical properties. Test their influence on each other’s physical properties beforehand to ensure that there are no problems.

- Examples of Applications

PELESTAT HC6800 has been used as a permanent antistatic agent in styrene resins such as ABS

resins, HIPS resins and MS resins (including transparent ABS resins and MBS resins), as well as

polyester resins such as PBT, nylon resins and PC / ABS alloys in the following applications:- Household electrical goods, office equipment, etc.

- Housings and storage cases of video game hardware, magnetic tapes, etc.

- Lighting fixture covers, meter panels, etc.

- Trays and containers for electric and electronic parts, etc.

Properties

- Appearance

- Pale yellow pellet

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (at 215°C 419°F, 21.18 N) | approx. 30 | g/10min | ASTM D 1238 |

| Melting Point | approx. 199 (390) | °C(°F) | DSC, ASTM D 3418 |

| Reduced Viscosity (0.5 wt % formic acid solution at 25°C, 77 °F) | approx. 1.7 | — | — |

| Refractive Index (at 23°C 73°F) | approx. 1.51 | — | ASTM D 542 |

| Surface Resistivity | approx. 3 × 10^7 | Ω | ASTM D 257 |

| Thermal Degradation Temperature | approx. 285 (545) | °C(°F) | — |

Regulatory & Compliance

- Patent Registered

USP 5,652,326 EP 0,613,919 USP 5,886,098 TW NI - 83,929 USP 5,604,284 KR 300,273

Technical Details & Test Data

- Performance Test

The examples on pages 4 to 8 are the results of performance tests using ABS resins mixed with

PELESTAT HC6800.

This product imparts a permanent antistatic property to these thermoplastic resins that cannot be attained by any other conventional blend-type, low-molecular-weight antistatic agent. Furthermore, this product minimally affects the physical properties of these thermoplastic resins because this product is highly compatible with them.

1. Application to ABS Resins

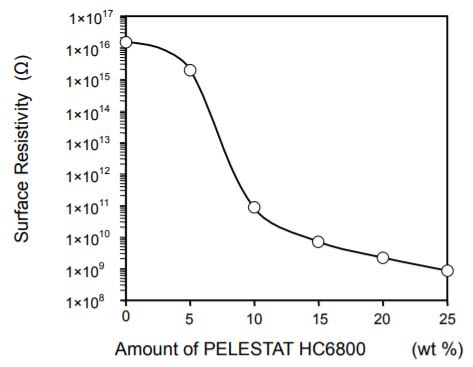

A. Relationship Between Amount of PELESTAT HC6800 and Resulting Surface Resistivity The ABS resin containing PELESTAT HC6800 is highly antistatic when the amount of this product added is between 10 and 20 wt %. Refer to Figure 3 and determine the optimal amount according to the desired surface resistivity.

Amount of PELESTAT HC6800 (wt %)

Relationship Between Amount of PELESTAT HC6800 and Surface Resistivity

Materials and Methods:

Materials:

A predetermined amount of PELESTAT HC6800 was dry-blended with the ABS resin {standard and high impact grade, MFR [220 °C (428 °F), 98.1N]: 17g (10min)} and the mixture was kneaded using a twin-screw extruder at approx. 230 °C (446 °F). The kneaded compound was then molded using an injection molding machine [nozzle temperature: approx. 230 °C (446 °F), mold temperature: approx. 50 °C (122 °F)] into samples 2 mm (approx. 0.08 inches) in thickness.

Method:

Each sample was kept at 23 °C (73 °F), 50 % R.H. for 24 hours. Then, the surface resistivity of each was measured using a megohmmeter according to ASTM D 257.B. Effect on Surface Resistivity When Repeatedly Washed with Water (Evaluation of Durability of Antistatic Effect)

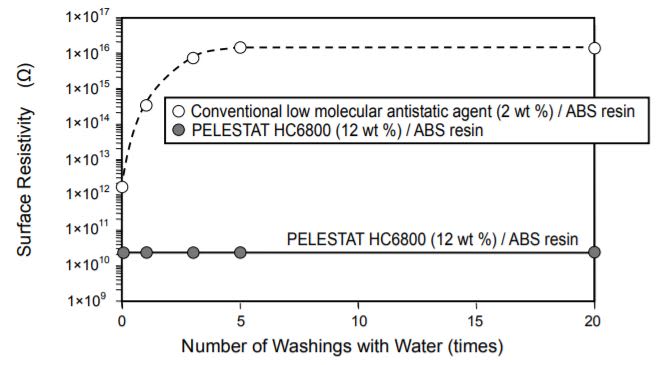

The surface resistivity of the ABS resin blended with PELESTAT HC6800 minimally changes, remaining antistatic even when washed with water. This product imparts a permanent antistatic property that cannot be attained by any other conventional blend type, low-molecular-weight antistatic agent, which loses its antistatic property after being washed with water approximately three times.

Number of Washings with Water (times)

Figure 4. Effect on Surface Resistivity When Repeatedly Washed with Water

Materials and Methods:

Materials:

PELESTAT HC6800 (12 wt %) / ABS resin

PELESTAT HC6800 (12 wt %) was dry-blended with the ABS resin and the mixture was using a twin-screw extruder at approx. 230 °C (446 °F). The kneaded compound was then molded using an injection molding machine [nozzle temperature: approx. 230 °C (446 °F); mold temperature: approx. 50 °C (122 °F) ] into samples 2 mm (approx. 0.08 inches) in thickness. Conventional low-molecular-weight anionic antistatic agent (2 wt %) / ABS resin

A conventional blend-type, low-molecular-weight antistatic agent, a Sanyo Chemical product, was applied. These samples were prepared by using the method described above.

Method:

Each sample was submerged in water and their surfaces were rubbed with cotton cloth. The samples were dried under reduced pressure [133 Pa (0.02 psi)] at 70 °C (158 °F) for 2 hours and were kept at 23 °C (73 °F), 50 % R.H. for 24 hours. The surface resistivity was measured using a megohmmeter according to ASTM D 257. This process was repeated according to the number of washings with water as described in Figure 4.C. Effect of Humidity on Surface Resistivity

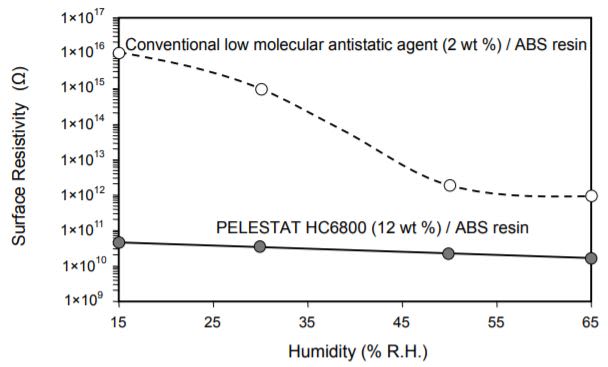

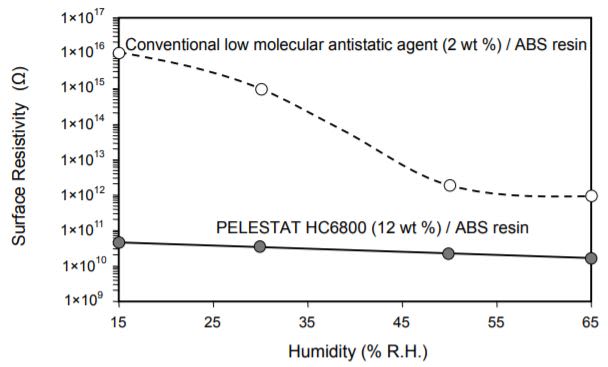

The surface resistivity of the ABS resin blended with PELESTAT HC6800 minimally changes even in low humidity due to this product’s low dependency on humidity. Conversely, an ABS resin blended with any other conventional low-molecular-weight antistatic agent loses its antistatic property in low humidity.

Humidity (% R.H.)

Effect of Humidity on Surface Resistivity

Materials and Methods:

Materials:

See Figure

Method:

Each sample was kept at 23 °C (73 °F) at a predetermined humidity for 24 hours. Then, the surface resistivity of each was measured using a megohmmeter according to ASTM D 257.D. Effect on Resin Physical Properties As shown in Table 1, PELESTAT HC6800 minimally affects the ABS resin physical properties.

Property Method

(ASTM No.)PELESTAT HC6800

(12 wt %) / ABSABS Resin Surface Resistivity D 257 3 × 10^10 > 10^16 Tensile Strength D 638 41 (5,900) 42 (6,100) Flexural Modulus D 790 2,100 (304,500) 2,300 (333,500) Izod impact strength (notched) D 256 220 (4.1) 240 (4.5) Deflection temp. under load (1.82 MPa) °C (°F) D 648 86 (187) 90 (194) Materials and Methods:

Materials:

Surface resistivity

PELESTAT HC6800 (12 wt %) was dry-blended with the ABS resin and the mixture was molded using an injection molding machine under the same conditions as described in Figure 4 into samples 2 mm (approx. 0.08 inches) in thickness. ABS resin was also molded under the same conditions.

Other mechanical properties

Samples were prepared under the same conditions described in Figure 4 except that the predetermined size described in ASTM was applied.Methods:

See the ASTM No. described in Table 1.(The testing method for surface resistivity is described in Figure)E. Ion Elution Properties

PELESTAT HC6800 is applicable to electric and electronic parts because it contains almost no halogen ions such as chlorine ions or alkali metal ions.Ion Elution Properties

Ionic specie Detection limit Measurement value Cl- 0.1 ppm Not detected Na+ 0.1 ppm Not detected K+ 0.1 ppm Not detected Materials and Methods:

Materials:

A predetermined amount of PELESTAT HC6800 was molded using an injection molding

machine [nozzle temperature: approx. 230 °C (446 °F); mold temperature: approx. 50 °C

(122 °F)] into boards sized 80×80×2 mm (approx. 3.15×3.15×0.08 inches) as samples.

Method:

The sample was immersed in 128 mL of ultrapure water at 80 °C (176 °F) for 60 min. The eluted ions were quantitated by the ion chromatography.F. Dispersibility of PELESTAT HC6800 in ABS Resins

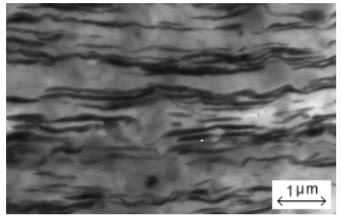

As shown in Figure , PELESTAT HC6800 is finely dispersed in the ABS resin.

Figure. Transmission Electron Micrograph of Molding (TEM photo)

Composed of PELESTAT HC6800 (12 wt %) and ABS Resin Explanation of Photograph]

Black stripes: PELESTAT HC6800 Circular form: Butadiene component of ABS resin

Figure is a magnification (approx. 10,000 times) of a cross section of the PELESTAT HC6800 12 wt %) / ABS resin mixture described in Figure 4. This product (black stripes) is dispersed in ABS resin (white portion) and works as a conductive network.2. Application to MS Resin

A. Effect on MS Resin Physical Properties

As shown in Table 2, PELESTAT HC6800 imparts a permanent antistatic property to the MS resin. The compatibility of this product with this resin is excellent, and the MS resin physical properties show minimal change.Property Method

ASTM No.PELESTAT HC6800

(10 wt %) / MS ResinMS Resin Surface Resistivity Ω D257 6 × 10^10 > 10^16 Total light transmittance % D1003 90.0 91.0 Haze % D1003 5 4 Tensile strength MPa (psi) D638 43 (6,200) 45 (6,500) Flexural modulus MPa (psi) D790 2,000 (290,000) 2,000 (290,000) Izod impact strength (notched) J/m (ft・lbf/in) D256 130 (2.4) 140 (2.6) Deflection temp. under load (1.82 MPa) °C (°F) D648 78 (172) 80 (176) *1 Refractive index of the resin: approx. 1.51 [23 °C (73 °F)]

Materials and Methods:

Materials:

PELESTAT HC6800(10 wt %) / MS resin

PELESTAT HC6800 (10 wt %) was dry-blended with the MS resin {MFR [220 °C (428 °F), 98.1N]: 29g (10min), refractive index: approx. 1.51} and the mixture was kneaded using a twin-screw extruder at approx. 230 °C (446 °F).

The kneaded compound was then molded using an injection molding machine [nozzle

temperature: approx. 230 °C (446 °F); mold temperature: approx. 50 °C (122 °F)] into a

predetermined sample.

MS resin

MS resin was molded under the conditions described above.Methods:

See the ASTM No. described in Table 2.

Surface resistivity

The samples of 2 mm (approx. 0.08 inches) in thickness were kept at 23 °C (73 °F) and 50 % R.H. for 24 hours. The surface resistivity of each was measured using a megohmmeter according to ASTM D 257.

Total light transmittance and haze

The samples were kept at 23 °C (73 °F) and 50 % R.H. for 48 hours. Total light transmittance and haze were measured using a hazemeter according to ASTM D 1003.B. Relationship between Amount of PELESTAT HC6800 and Resin Optical Property

PELESTAT HC6800 has a refractive index of approx. 1.51. When this product is added to the MS resins (refractive index: 1.51 – 1.57), this product minimally affects the resins’ transparency.

Amount of PELESTAT HC6800 (wt %)

Figure . Relationship Between Amount of PELESTAT HC6800 and Resin Optical Property Materials and Methods:

Materials: See table 3 except that amount (described in Figure 7) of PELESTAT HC6800 was dry-blended with the MS resin [refractive index: approx. 1.51, 23 °C (73 °F)].

Method:

See Table 3 (ASTM D 1003).