Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Composites Processing Methods

Properties

- Color

- Appearance

- Clear yellowish brown resin

- Typical Cast Resin Properties - Base Resin

- Uncured Properties

- Note

- * Curing schedule - 24 hours at 20°C/ 68°C, 5 hours at 80°C/ 176°C

- ** CTE as measured by TMA, ASTM E 831

- Water Absorption Data

Avg Gain/ mg Avg Gain/ % 24 hours 6.5 0.08 1 week 17.1 0.20 4 weeks 20.8 0.24 BS EN ISO 62:1999. 50x50x3mm sample size. Water bath 23oC/ 73oF. Cast resin, cure: 2% of 1% solution cobalt in styrene, + 2%LPT-IN. Post Cure: 16 hours at 40°C/ 104°F (Lloyd’s).

| Value | Units | Test Method / Conditions | |

| Barcol Hardness | 55 | — | — |

| Heat Deflection Temperature | 109 | °C | — |

| Tensile Strength* | 76 | MPa | — |

| Tensile Modulus* | 3.6 | GPa | — |

| Elongation (at Break)* | 2.7 | % | — |

| CTE - Alpha 1** | 65 | ppm (°C)-1 | — |

| CTE - Alpha 2** | 200 | ppm (°C)-1 | — |

| Tg - TMA (Onset) | 100 | °C | — |

| Tg - TMA | 112 | °C | — |

| Tg - TMA (Exit) | 125 | °C | — |

| Value | Units | Test Method / Conditions | |

| Viscosity (at 25°C, 4500 s⁻¹) | 2.25 | Poise | — |

| Density (at 25°C) | 1.038 - 1.042 | g/cm³ | — |

| Stability in the Dark (at 20°C) | 12 | months | — |

Technical Details & Test Data

- Technical Support

A non-exclusive list of factors to consider when optimizing a pultrusion manufacturing process are:

- Reinforcement type

- Resin type

- Resin/reinforcement ratio

- Resin temperature

- Profile shape

- Profile thickness

- Die length

- Die heating method (oil, electric, water)

- Peroxide package

- Die temperature set points

This is an example start point formulation/set up, however, for the factors listed above, there will be some local optimizing required to maximize productivity. Fiber volume fraction of >70% is achievable with this resin.

Component Parts Crestapol 1250 100.00 Internal Release Agent 1.25 - 1.50 Trigonox HM (or equivalent) 1.25 Trigonox C (or equivalent) 1.25 Calcium Carbonate 5 Typical starting set point temperatures (based on 500mm die with 5 equal zone lengths)

Component Temp (°C) Temp (°F) Zone 1 145 293 Zone 2 165 329 Zone 3 195 383 Zone 4 210 410 Zone 5 (cooling zone) 10 50 - Abrasion Data

- Accelerated wear testing was performed by doing a Taber Abrasion test to ASTMD4060. After 4000 abrasion cycles, Crestapol 1250 lost 190mg.

- Impact Resistance Data

ASTM D 4226 Standard Test Method for Impact Resistance of rigid Poly Vinyl Chloride building products was conducted by Professional Engineering Inc. to determine what affect impact at extreme temperatures would have on the composite material. Tests to be conducted at -54°C, ambient, and 71°C/160°F, on thirty samples at each temperature. All samples were conditioned for at least 24 hours then immediately tested to maintain the temperature of the test specimen. An 8.4lb weight was dropped from various heights to determine if the fibers broke in the composite material. For purposes of customer testing, the failure criteria would be no permanent deformation or breakage of the skin material. There was no permanent deformation or breakage observed.

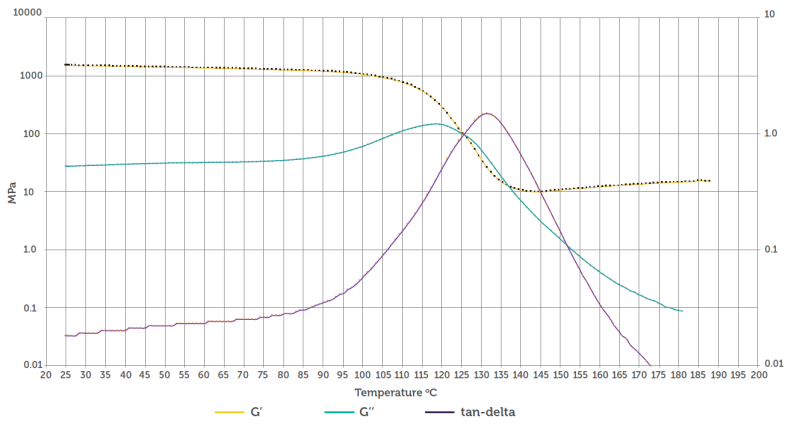

Temperature Failure Height Damage Observed -54ºC/ -65ºF 32cm - 38cm Broken fibers Ambient 28cm - 34cm Broken fibers 71ºC/ 160ºF 28cm - 32cm Broken fibers Temperature effects on modulus - Tg onset g’ 109°C/ 227°C

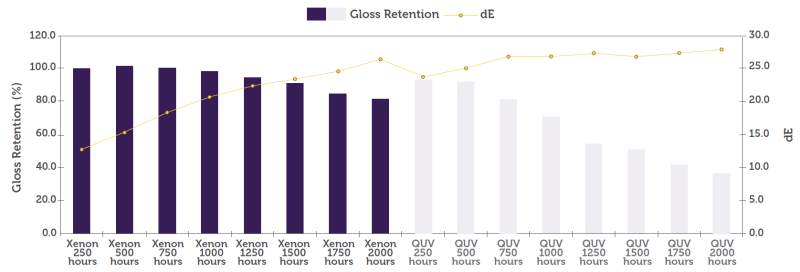

- UV Weathering Data

Results: Crestapol 1250 & 1260

The resin color-shifted but no fiber bloom detected, meaning the resin did not degrade.

Panel Description

Laminate lay up as follows:

- 9” x 9” square

- 2 x glass tissue on tool side

- 2 x 450gsm powder pound CSM

- Peel ply and infusion flow media on bag side only

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging

Crestapol 1250 is supplied in 25kg/6.6 gallon, 200kg/53 gallon and 1000kg/264 gallon pack sizes.

Storage & Handling

- Storage

Crestapol 1250 should be stored ar 25°C/77°C in the original, unopened container in a dry, well ventilated place Protect from freezing and direct sunlight. Avoid contact with oxidizing agents. The shelflife is defined from date of manufacture when stored as recommended.