Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features and Benefits

- Urethane acrylate base

- Low density adhesive

- Reduced core print through

- Highly thixotropic

- Color change system

- Excellent adhesion and high elongation at break

- Reduced weight of end product

- Improved esthetics and surface finish

- No sagging on vertical surfaces

- Visual check for effective catalyst mix

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Recommended Applications

- Crestomer® 1196PA is supplied pre-accelerated. The required hardener is a medium reactivity MEKP catalyst. The catalyst is added at 2% w/v. Crestomer® 1196PA can be applied with a spatula or from a dispensing unit capable of achieving a volumetric ratio of 92:1 taking care to keep air entrapment to a minimum. Care needs to be taken on the pressure settings to ensure that the microspheres within the adhesive are not crushed, which adversely affects the viscosity of the material. Application should always be carried out at temperatures above 15°C/ 59°F. The recommended temperature range is between 18°C and 25°C/ 66°F and 77°F.

- After application, a saw cut toothed comb should be used to meter the adhesive into peaks. A comb with a 4-5mm edge will meter sufficient adhesive for most applications. Crestomer® 1196PA is designed to allow full penetration of the core with a simple consolidation roller used to remove air from laminates. Penetration can be further ensured by the use of a vacuum bag; typical pressures of 0.04 – 0.07 MPa (6-10lb/square inch) are sufficient to ensure good contact.

- For industrial/commercial use only. The user must determine the suitability of a selected adhesive for a given substrate and application. Contact your local Scott Bader representative for questions or assistance with the selection of adhesives for your use. This product is intended for use by skilled individuals at their own risk. Recommendations contained herein are based on information we believe to be reliable. The properties and strength values obtained under controlled conditions at the Scott Bader laboratory.

- Coverage

Coverage is variable depending on the laminate contour uniformity and core material thickness. For 10mm/ 0.4 inch thick square cut foam, an adhesive thickness of about 1.5mm/ 0.06 inch should give adequate bond thickness and cut penetration. For 20mm/ 0.8 inch thick core material, 2.5mm/ 0.1 inch adhesive thickness may be necessary.

Coverage

Adhesive Thickness Coverage 1.5mm 1.5 Liters (0.9Kg) 2.5mm 2.5 Liters (1.5Kg)

Properties

- Appearance

- Pink paste

- Mechanical Properties

- Typical Properties

- Application Properties

- Note

- Geltime measured with 100g mass of adhesive at 25°C/ 77°F. Using 2% Butanox M50 catalyst.

- Time taken at 23°C / 73°F (ambient temperature) to achieve 1.4MPa strength in lap-shear tests according to BS ISO.

- Measured using Brookfield Viscometer at 25°C (77°F)

- Mix ratio based on volume and weight for both machine dispensing and hand mixing

- The shelf life for Crestomer® products is defined from the date of manufacture if stored as recommended. The expiry date is indicated on the product labels.

- Test to BS EN ISO 527-2

- BS EN ISO 62

- Test to ASTM C297 / C97M

- Metals test to ASTM D1002 for Lap Shear Strength, Composites and Marine Ply test to ASTM 5868 for Lap Shear Stength, Balsa tested to ASTM D3807 for Cleavage Peel. All at 23°C (73°F)

- Adhesive Failure When Tested

- Substrate Failure When Tested

- Cohesive Failure When Tested

| Value | Units | Test Method / Conditions | |

| Hardness | 70 | Shore D | — |

| Tensile Strength⁶ | 13 - 16 | MPa | — |

| Tensile Modulus⁶ | 700 - 900 | MPa | — |

| Tensile Elongation⁶ | 4 - 7 | % | — |

| Water Absorption⁷ | 0.43 | % | — |

| Tensile Strength (Balsa)⁸ | 10.2 | MPa | — |

| Tensile Strength (PVC Foam) | 6.3 | MPa | — |

| Value | Units | Test Method / Conditions | |

| Specific Gravity | 0.6 | — | — |

| Volatile Content | 45 | % | — |

| Viscosity³ | 250,000 - 320,000 | cP | — |

| Mixed Ratio⁴ (by volume) | 50:1 | — | — |

| Value | Units | Test Method / Conditions | |

| Working Time¹ | 50 | Minutes | — |

| Fixture Time² | 6.5 | Hours | — |

| Gap Filling | 1 - 30 | — | — |

| Color Change (over cure) | Purple to pink | — | — |

| Recommended Application Temperature | 18 - 25 | °C | — |

Technical Details & Test Data

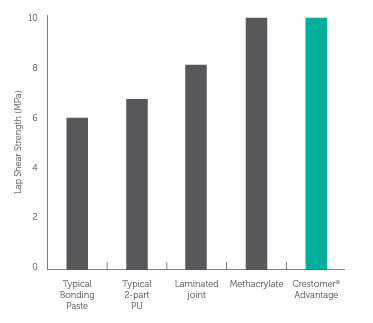

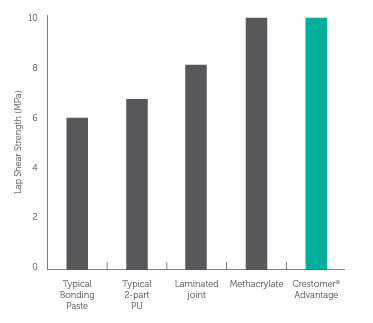

- Comparisons with Competitive Materials

Crestomer® adhesives are one of a wide variety of materials that can be used in bonded assemblies. Compared to other adhesives, Crestomers offer the following benefits:

- Monomer type identical to polyester resins

- Cured with conventional peroxides

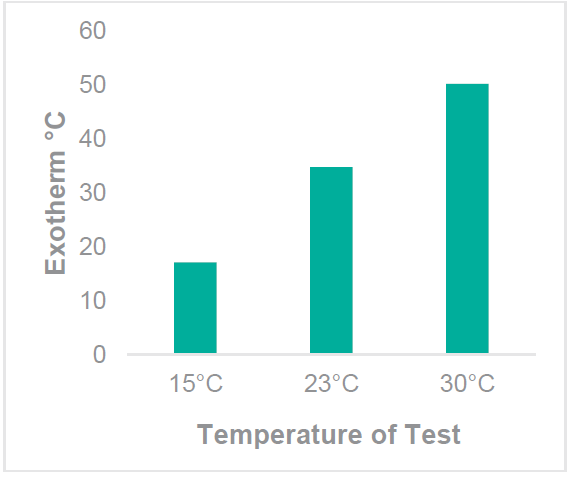

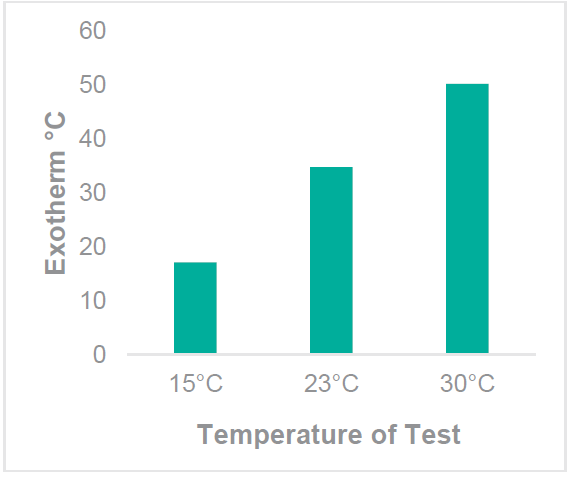

- Low exotherm during cure

- Available in a range of working and fixture times

- Ease of application

- Cost effective

High exotherm in an adhesive can cause the substrate to distort and give poor esthetic characteristics to the parts being bonded. The chemistry of Crestomer® adhesives ensures

that high exotherm temperatures, a characteristic of some other adhesives do not occur. The graph shows the exotherm temperatures of Crestomer® adhesives over a range of test temperatures.FRP to FRP bond strength

Exotherm of Crestomer® adhesives

High exotherm in an adhesive can cause the substrate to distort and give poor aesthetic characteristics to the parts being bonded. The chemistry of Crestomer® adhesives ensures that high exotherm temperatures, a characteristic of some other adhesives, does not occur. The graph shows the exotherm temperatures of Crestomer® adhesives over a range of test temperatures.

- Core Preparation

Priming the core material is essential. It ensures complete wetting of the core material and in the case of balsa, it also effectively seals the grain against potential cracking in the event of minor gelcoat or laminate damage. To prime the core, a light coat of catalyzed resin should be evenly sprayed or rolled onto the core surface. The primer resin does not need to be cured before the core can be pushed onto the Crestomer 1196PA. Crystic polyester resins such as 2.406PA, 414PA and 489PA can be used as the primer resin, although it is recommended that test panels of desired constructions are made to confirm performance.

- Recommended Substrates

Crestomer® adhesives are one of a wide variety of materials that can be used in bonded assemblies. Compared to other adhesives, Crestomers offer the following benefits:

- Monomer type identical to polyester resins

- Cured with conventional peroxides

- Low exotherm during cure

- Available in a range of working and fixture times

- Ease of application

- Cost effective

High exotherm in an adhesive can cause the substrate to distort and give poor esthetic characteristics to the parts being bonded. The chemistry of Crestomer® adhesives ensures

that high exotherm temperatures, a characteristic of some other adhesives do not occur. The graph shows the exotherm temperatures of Crestomer® adhesives over a range of test temperatures.FRP to FRP bond strength

Exotherm of Crestomer® adhesives

High exotherm in an adhesive can cause the substrate to distort and give poor esthetic characteristics to the parts being bonded. The chemistry of Crestomer® adhesives ensures that high exotherm temperatures, a characteristic of some other adhesives, does not occur. The graph shows the exotherm temperatures of Crestomer® adhesives over a range of test temperatures.

Packaging & Availability

- Country Availability

- Regional Availability

- Packaging

- Crestomer® 1196PA is supplied in 15Kg/ 30 lbs and 100Kg/ 220 lbs containers.

Storage & Handling

- Shelf Life

- 6 Months

- Storage

Crestomer® 1196PA should be stored in its original container and out of direct sunlight. It is recommended that the storage temperature should be between 15°C and 20°C/ 59°F and 68°F. Ideally, containers should be opened only immediately prior to use. Products should never be frozen.